Metal matrix self-lubricating composite material and preparation method thereof

A technology of self-lubricating materials and composite materials, applied in the field of metal-based self-lubricating composite materials and their preparation, can solve unsatisfactory problems and achieve good lubrication and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing a metal-based self-lubricating composite material, comprising the following steps:

[0029] a) Sintering copper alloy powder on the surface of the metal substrate to form a copper alloy layer on the surface of the metal substrate;

[0030] b) Scraping or dip-coating a self-lubricating material on the surface of the copper alloy layer, then vacuumizing to obtain a metal plate, and drying the metal plate;

[0031] c) repeat step b) multiple times;

[0032] d) Sintering the metal plate obtained in step c) to obtain a metal-based self-lubricating composite material.

[0033] According to the present invention, in the process of preparing the metal-based self-lubricating composite material, copper alloy powder is first sintered on the surface of the metal substrate to form a copper alloy layer on the surface of the metal substrate. Wherein, the metal substrate includes but not limited to carbon steel, stainless ste...

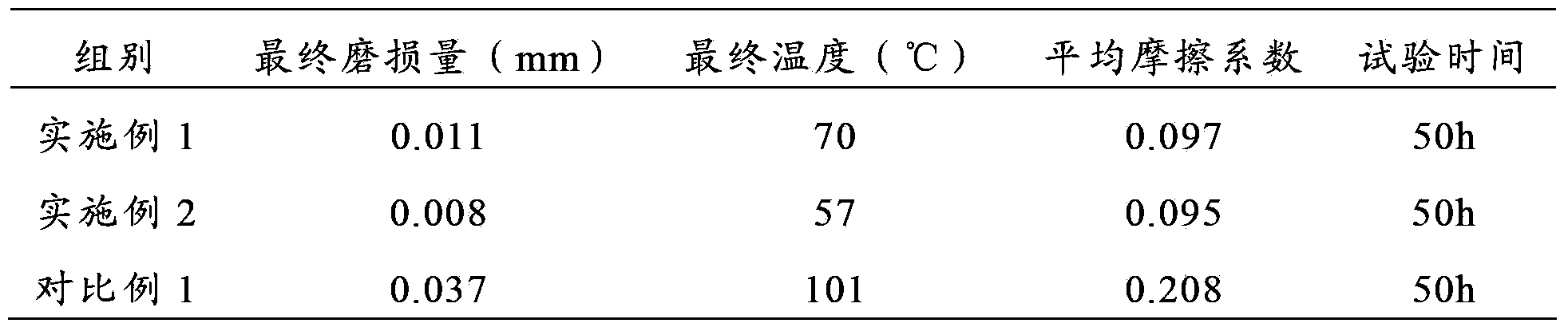

Embodiment 1

[0043] The 1.8mm cold-rolled carbon steel sheet provided by the company is used as the metal substrate, and the copper alloy powder with a particle size of 60-200 mesh is covered on one surface of the metal substrate. The copper alloy powder includes 10wt% tin, 10wt% lead and The remaining amount of copper; then the metal substrate is sintered in nine areas of the sintering furnace in sequence, the linear speed of the sintering is 260mm / min, the furnace temperature of the first to second areas of the sintering furnace is 750 ° C, and the third area to The furnace temperature in District 9 is 810°C. After the sintering is completed, a copper alloy layer is formed on the surface of the metal substrate, and the thickness of the copper alloy layer is 1.2±0.1mm;

[0044] Colloidal graphite, molybdenum disulfide and polytetrafluoroethylene are configured with 1000g of self-lubricating material according to the mass ratio of 0.25:1:3.5;

[0045] Use a scraper to scrape a layer of sel...

Embodiment 2

[0051] A 2mm cold-rolled carbon steel sheet is used as the metal substrate, and copper alloy powder with a particle size of 100 to 140 mesh is covered on one surface of the metal substrate, wherein the copper alloy powder includes 8wt% tin and the balance of copper; then the metal substrate Carry out sintering in nine areas of the sintering furnace in sequence, the linear speed of the sintering is 350mm / min, the furnace temperature of the first and second areas of the short plate furnace is 750°C, and the furnace temperature of the third area to the ninth area is 810°C , after the sintering is completed, a copper alloy layer is formed on the surface of the metal substrate, and the thickness of the copper alloy layer is 2.5mm;

[0052] Colloidal graphite, molybdenum disulfide and polytetrafluoroethylene are configured with 1000g of self-lubricating material according to the mass ratio of 0.25:1:3.5;

[0053] Use a scraper to scrape a layer of self-lubricating material on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com