Composite wear-resistant liner, wear-resistant alloy for making it and method for making it

A technology of composite wear-resistant lining plate and wear-resistant alloy, applied in the field of composite wear-resistant lining plate and manufacturing composite wear-resistant lining plate, can solve the problems of different performance, high density, affecting the service life, etc., and achieve high product yield, The preparation process is simple and the effect of good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

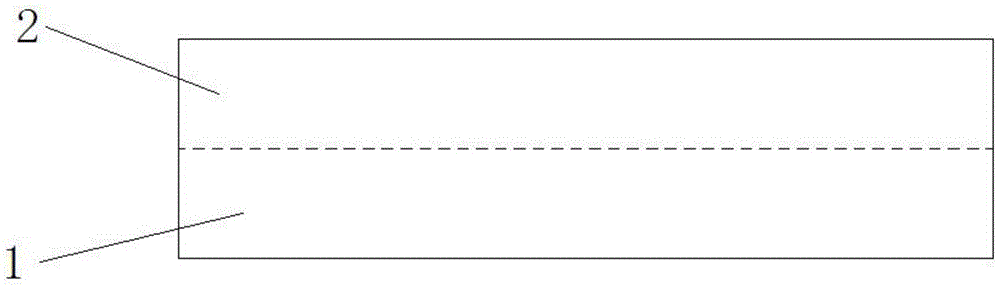

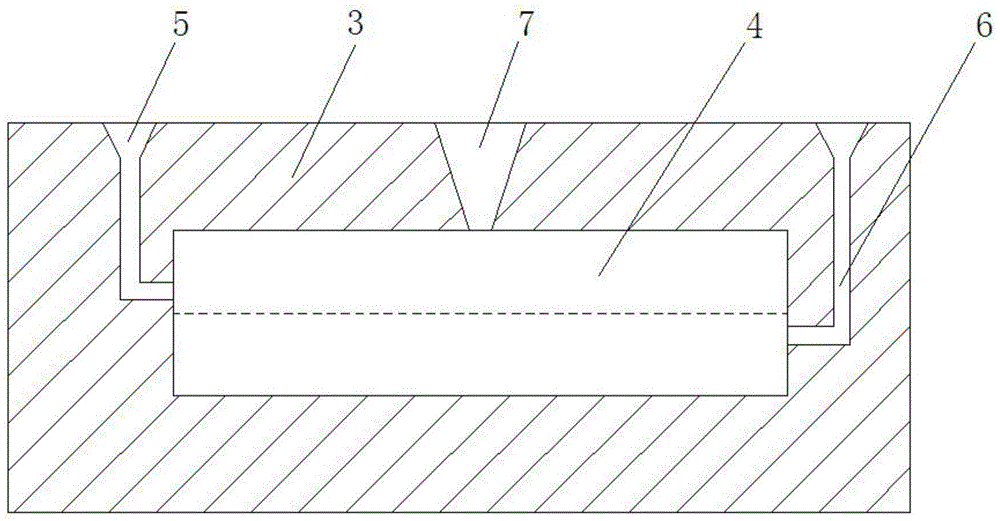

[0037] figure 1 Show the specific implementation of a composite wear-resistant lining board of the present invention: the composite wear-resistant lining board is composed of a wear-resistant layer 1 and a base layer 2, the wear-resistant layer 1 is made of wear-resistant alloy, and the base layer 2 is made of high-toughness steel Made of wear-resistant alloys made of Cr, C, Si, Mn, S, P, Mo, Ni, Cu, Re and Fe mixed. The high toughness steel is one of CA6WV, Cr4W2MoV or Cr12.

[0038] The invention relates to a wear-resistant alloy for manufacturing a composite wear-resistant lining plate. The weight percentages of the components in the wear-resistant alloy are as follows: Cr (14.0-25.0) W%, C (2.0-4.0) W%, Si (0.3- 1.2) W%, Mn (0.3-0.8) W%, S (0-0.015) W%, P (0-0.015) W%, Mo (0.2-2.0) W%, Ni (0-1.0) W%, Cu (0.3-1.2) W%, Re (0.2-0.4) W%, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com