Antirust oil composition and application thereof

A composition and technology of anti-rust oil, applied in the direction of lubricating composition and the like, can solve the problems of poor anti-lamination performance of anti-rust oil, etc., and achieve the effects of excellent anti-rust performance, easy removal and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

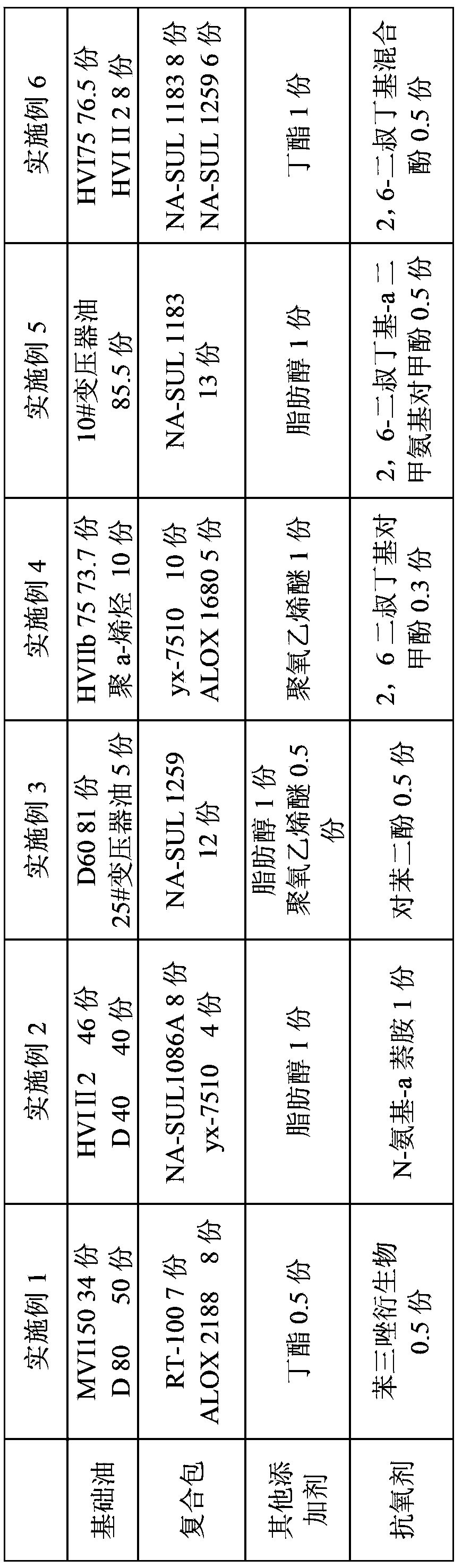

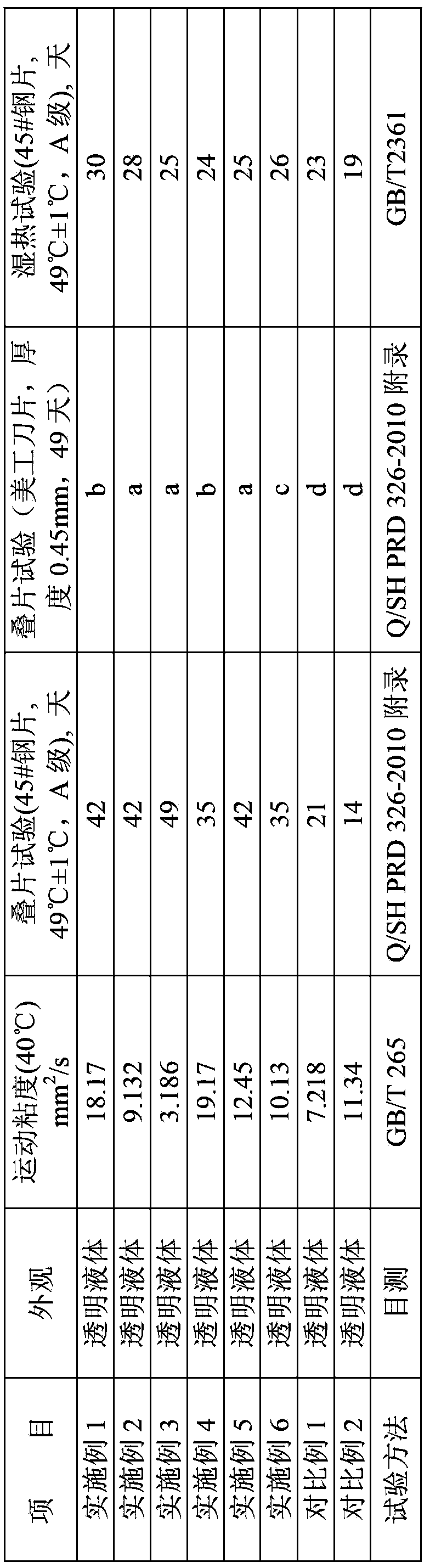

Embodiment 1~6

[0034] According to the parts by weight in Table 1, add the base oil into the blending kettle, heat and stir at 50°C, then add the oil-soluble antirust agent composite package, other additives, antioxidants, and stir at a constant temperature of 50°C for 2 hours to obtain the anti-corrosion agent of the present invention. Rust oil composition.

[0035] Among them, the composite package RT-100 is a product of Suzhou Runtian Company, the NA-SUL series is a product of King Company, the ALOX series is a product of Lubrizol Company, RP6073 is a product of Dongguan Sunwill Company, and yx-7510 is a product of Suzhou Yuanxing Company.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com