Induction heating device having temperature compensation function

A technology of induction heating device and temperature compensation, which is used in manufacturing tools, heat treatment equipment, and energy efficiency improvement. It can solve problems such as uneven temperature distribution and affect product quality, achieve uniform temperature distribution, avoid repeated disassembly, and small temperature difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

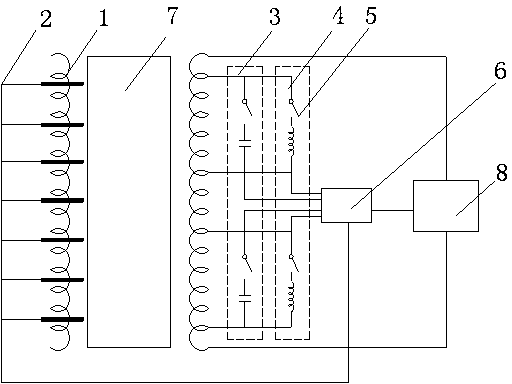

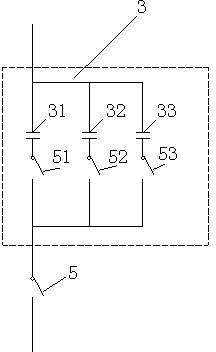

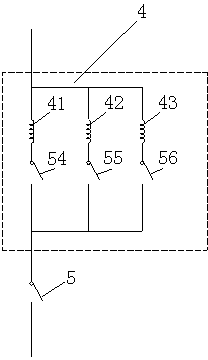

[0027] see figure 1 , an induction heating device with a temperature compensation function, comprising an inductor component 1, a temperature detection component 2, a PLC control system 6 and a compensation component, the compensation component includes several compensation units, the compensation unit includes a capacitance compensation unit 3 and an inductance compensation unit The unit 4, the capacitance compensation unit 3 and the inductance compensation unit 4 are respectively provided with an independent circuit breaker 5, and the capacitance compensation unit 3 and the inductance compensation unit 4 are connected in parallel, and the circuit breaker 5 is an electric circuit breaker; each compensation unit is connected in parallel with the inductor On the induction coil unit of the component 1, the circuit breaker 5 is connected to the PL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com