A vacuum isolation device for ultra-low temperature fluid transmission pipeline

A fluid transmission and ultra-low temperature technology, applied in the direction of heat preservation, pipe components, pipeline protection, etc., can solve the problems that vacuum partitions are not suitable, superfluid helium is not easy to store, and does not involve vacuum partitions, etc., to achieve the effect of reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

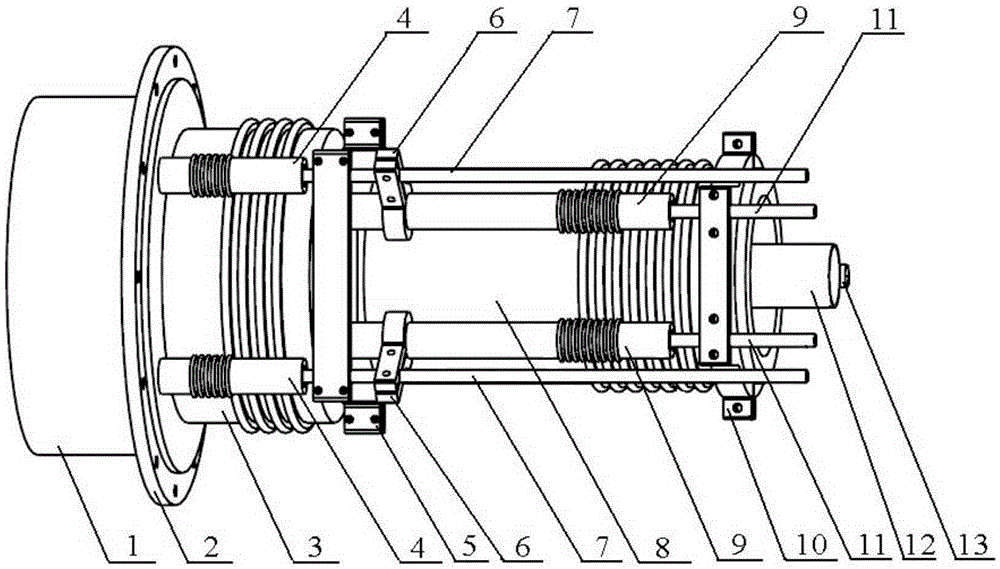

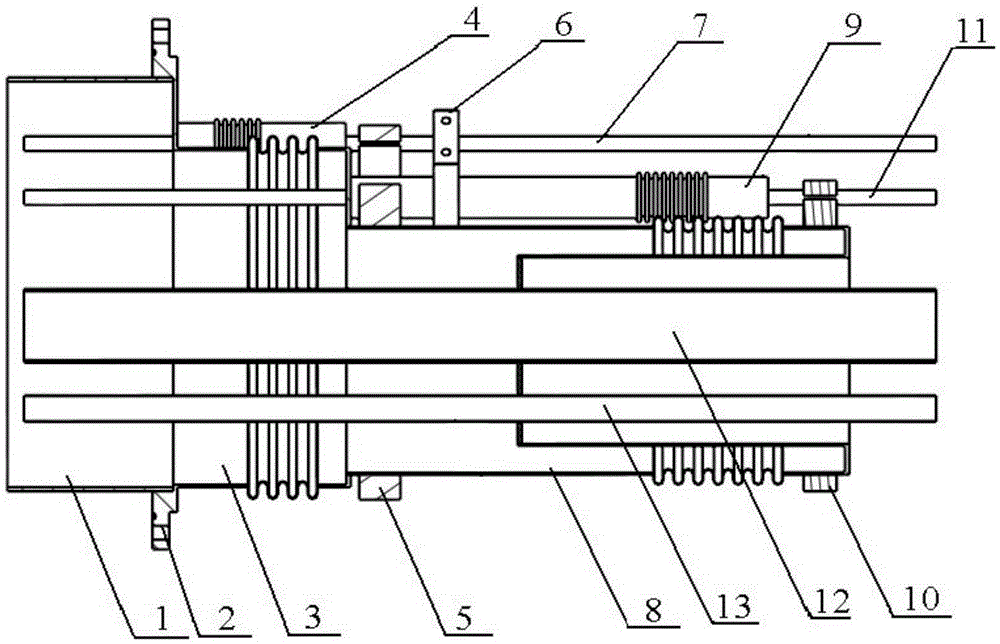

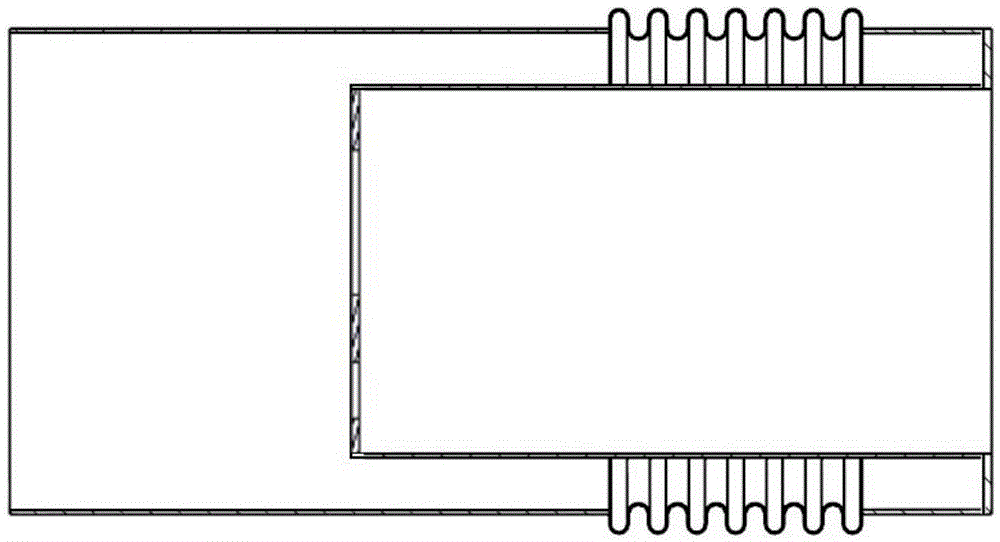

[0026] The vacuum isolation device in the 2K low-temperature transmission pipeline of the present invention includes the vacuum isolation flange of the 2K low-temperature transmission pipeline, low-temperature pipelines in different temperature zones and corresponding vacuum sleeve types. It is characterized in that the vacuum isolation device of the 2K low-temperature transmission pipeline includes low-temperature pipelines in different temperature zones, and the low-temperature pipelines in each temperature zone are equipped with double-layer sleeves with bellows, and at the same time, the low-temperature pipelines in each temperature zone are separated by copper cooling sinks. To establish a connection, the copper cooling sink of the upper temperature zone (that is, the adjacent higher temperature zone) is set in the appropriate position of the double-layer casing as a heat cut-off to selectively consume the fluid in the higher temperature zone to reduce the fluid consumption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com