High-flux plane light source device

A planar light source and high-flux technology, applied to gas discharge lamp parts, lamp parts, gas plasma lamps, etc., can solve problems such as multi-electrode arc discharge instability, arc chamber wall and transmission window pollution, damage, etc. , to achieve the effect of increasing window life, increasing arc power, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

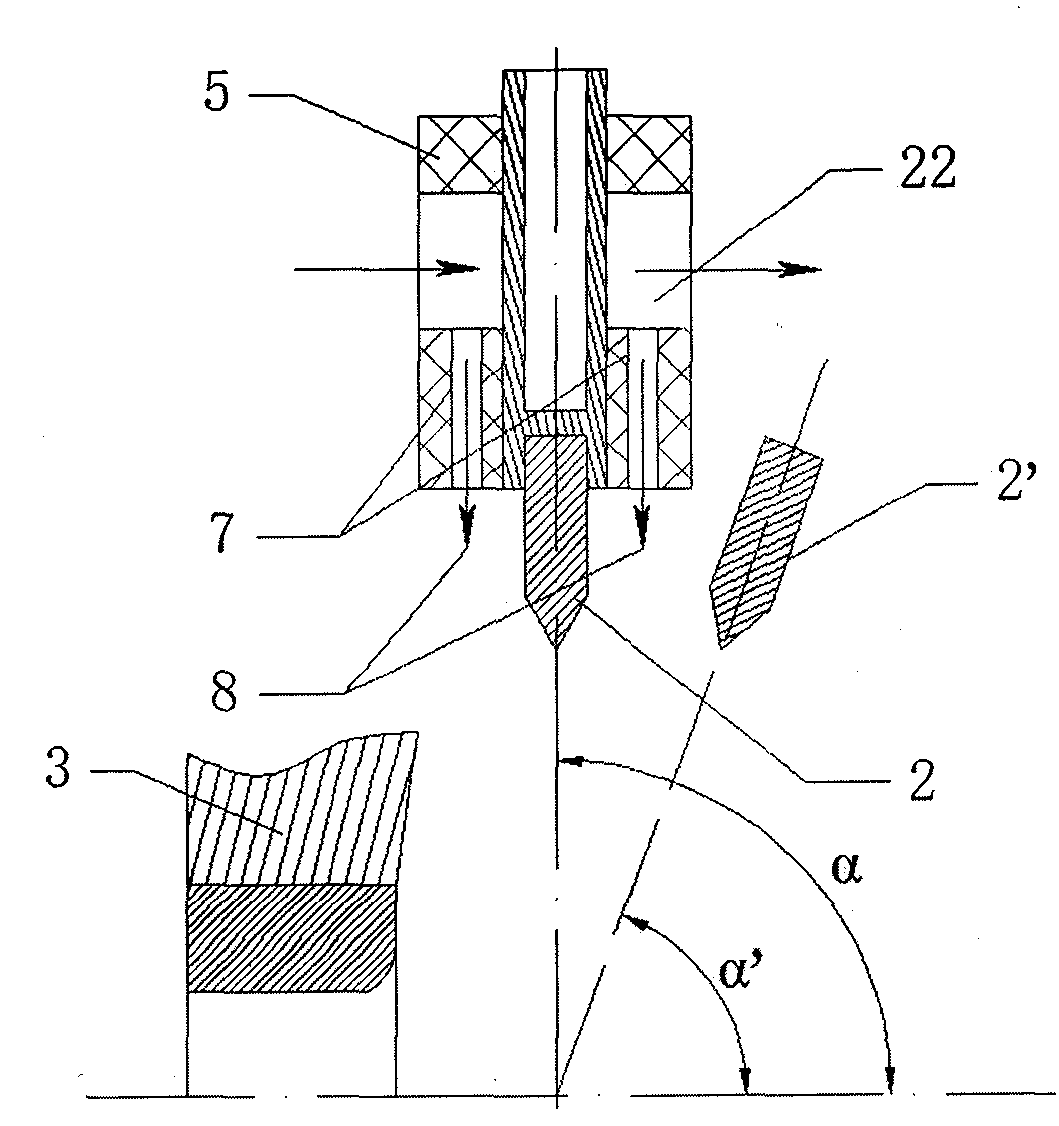

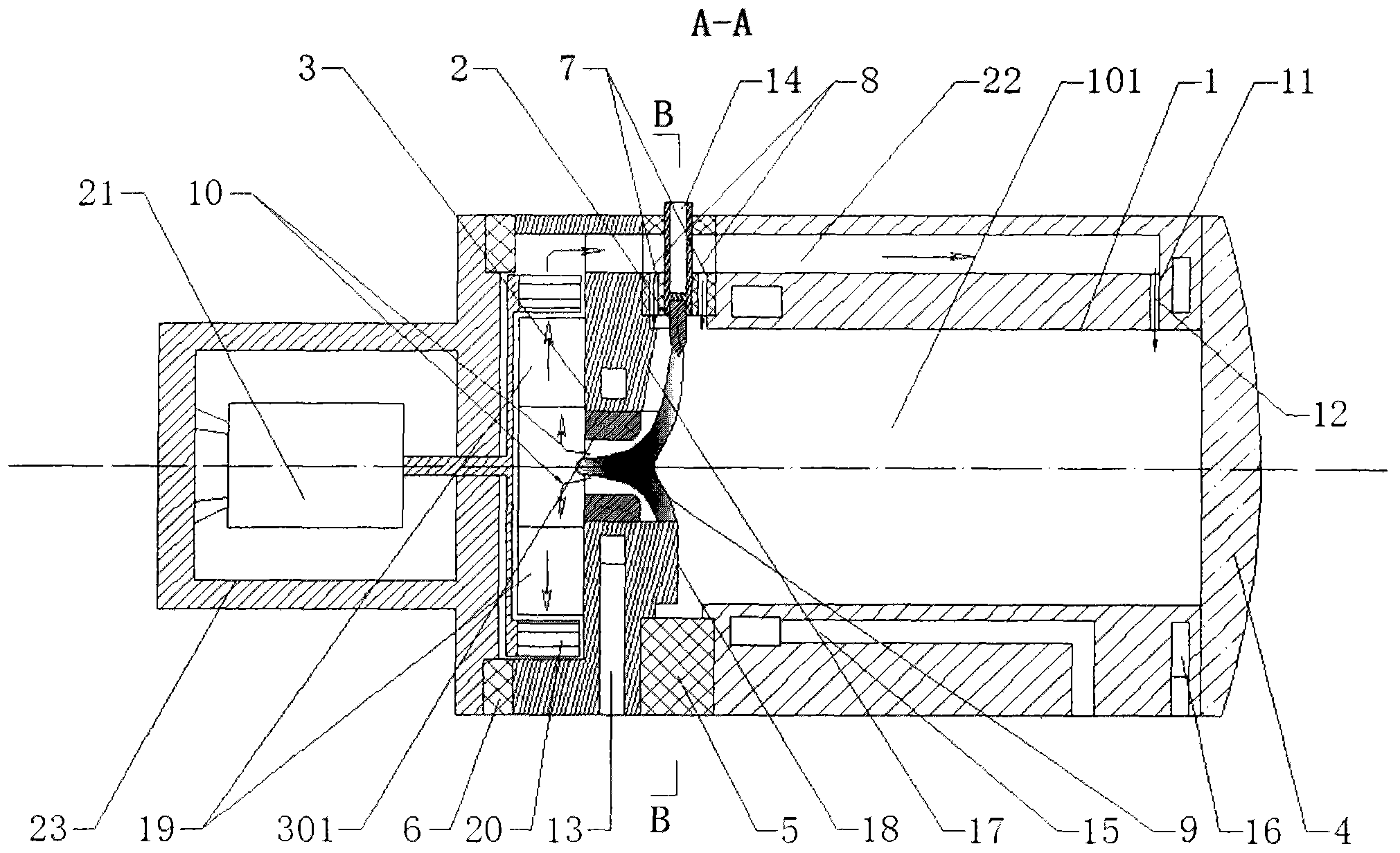

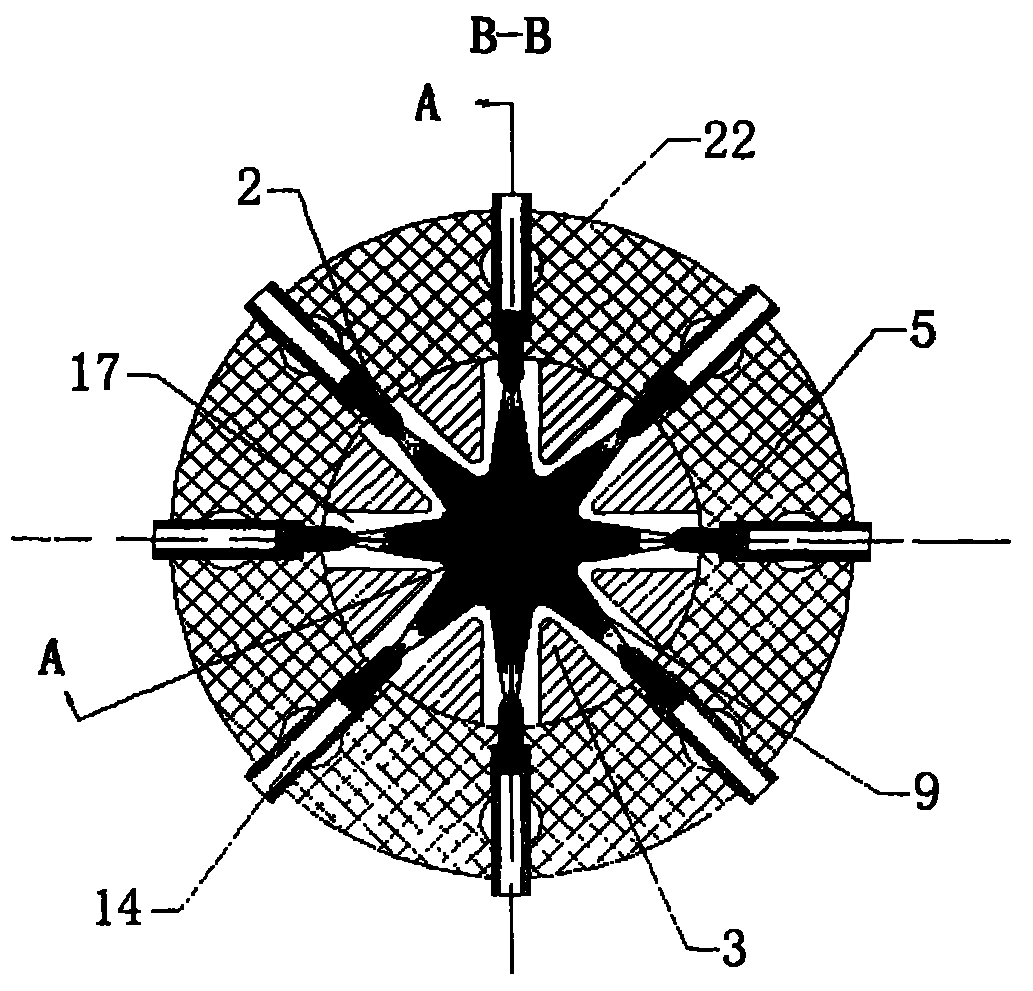

[0056] The main structural dimensions of the device: the diameter of the anode arc chamber is 100mm, the length of the arc chamber is 300mm; the number of rod-shaped cathodes is 8, and the diameter of the cathode is 6mm; the plate-shaped anode is composed of two parts, the center is a ring of pure tungsten metal, and the inner hole of the tungsten ring is the anode The circular hole has a diameter of 20mm, and the outer diameter of the tungsten ring is 30mm. The cathodes are arranged in the same plane, and the distance between the diagonal cathode tips is 80mm.

[0057] Electrode material: the rod-shaped cathode is lanthanum tungsten (containing 3% lanthanum oxide); the anode and arc chamber wall are T2 copper, and the surface is coated with aluminum film.

[0058] Inflatable pressure: 1MPa argon.

[0059] Arc current: each cathode current 200A, total current 1600A;

[0060] Arc voltage: 40V, arc power 64kW, arc radiation power over 10kW.

[0061] Compared with the "point" ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com