High-pressure stratification and spark ignition device for an internal combustion engine

A spark ignition, internal combustion engine technology, applied in spark ignition controllers, mechanical equipment, engine ignition, etc., can solve problems such as reducing filling capacity, reducing overall efficiency, and delaying the start of ignition, reducing fuel consumption and consumption. , Increase the effect of producing Chenben

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

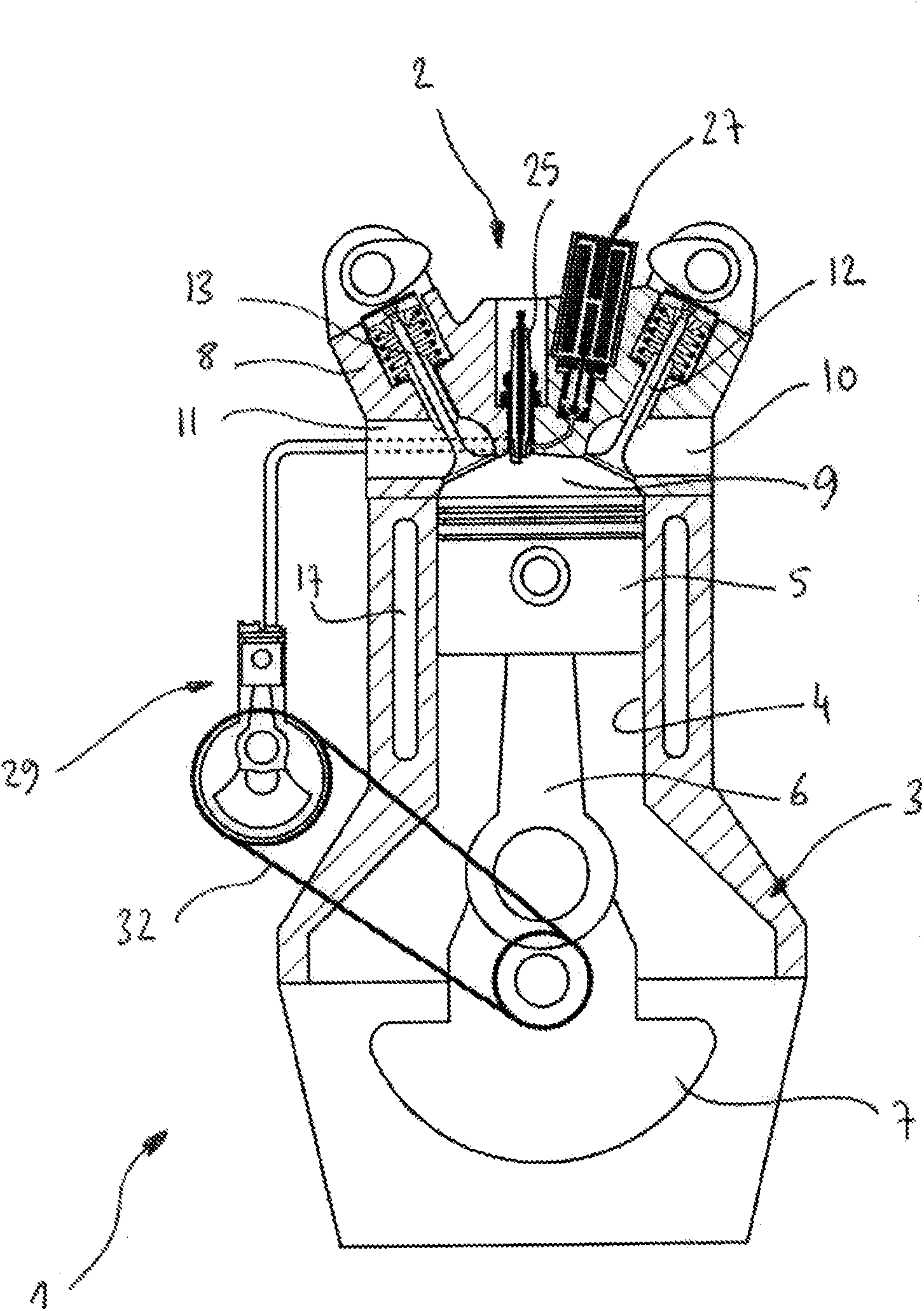

[0108] figure 1 An internal combustion engine 1 comprising a high-pressure spark ignition and stratification device 2 according to the invention is shown.

[0109] The internal combustion engine 1 comprises an engine block or crankcase 3 containing at least one combustion cylinder 4 closed by a cylinder head 8 and in which cylinder a combustion piston 5 moves.

[0110] The combustion piston 5 is articulated on a connecting rod 6 connected to a crankshaft 7 which transmits the movement of the combustion piston 5 to the crankshaft 7 as it moves within the combustion cylinder 4 .

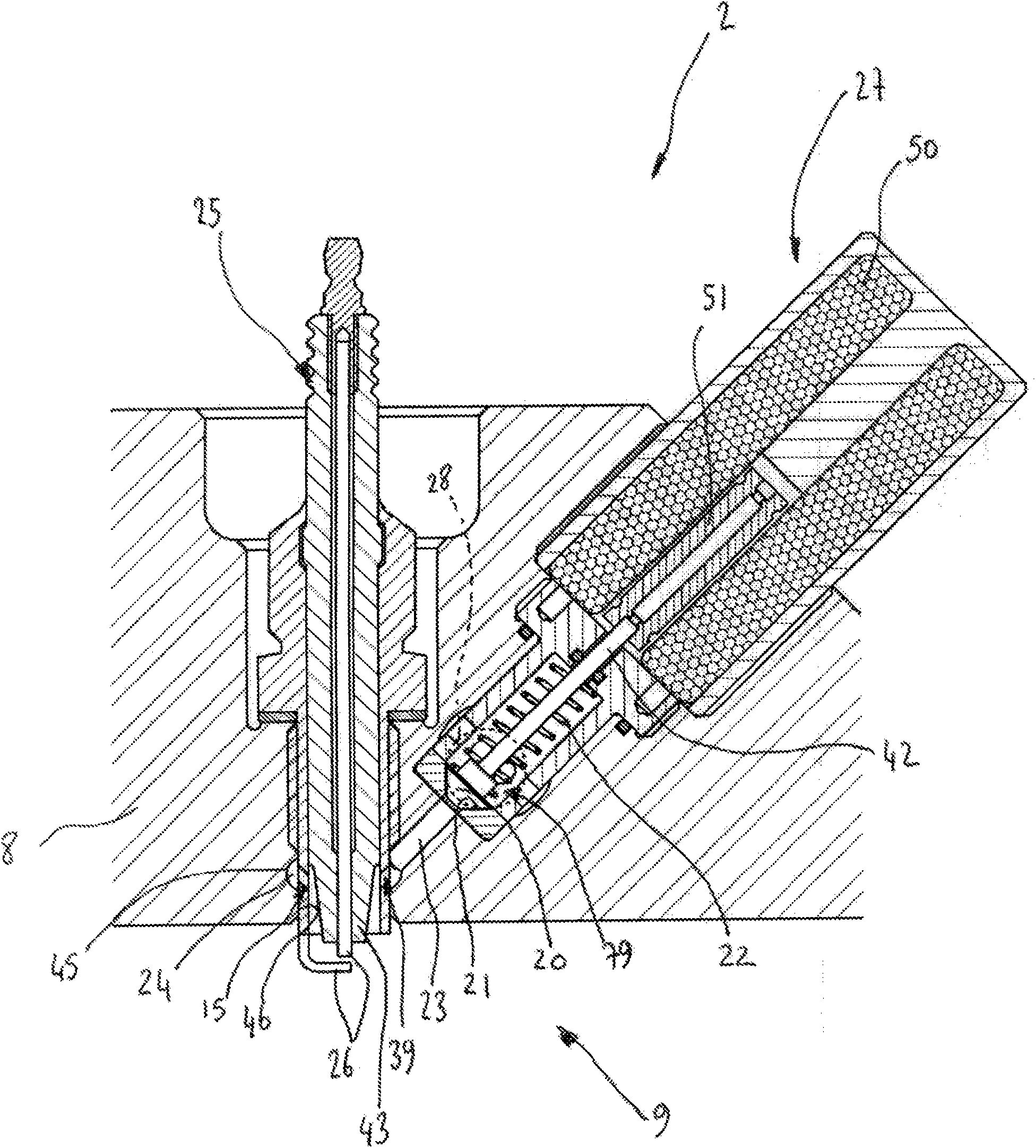

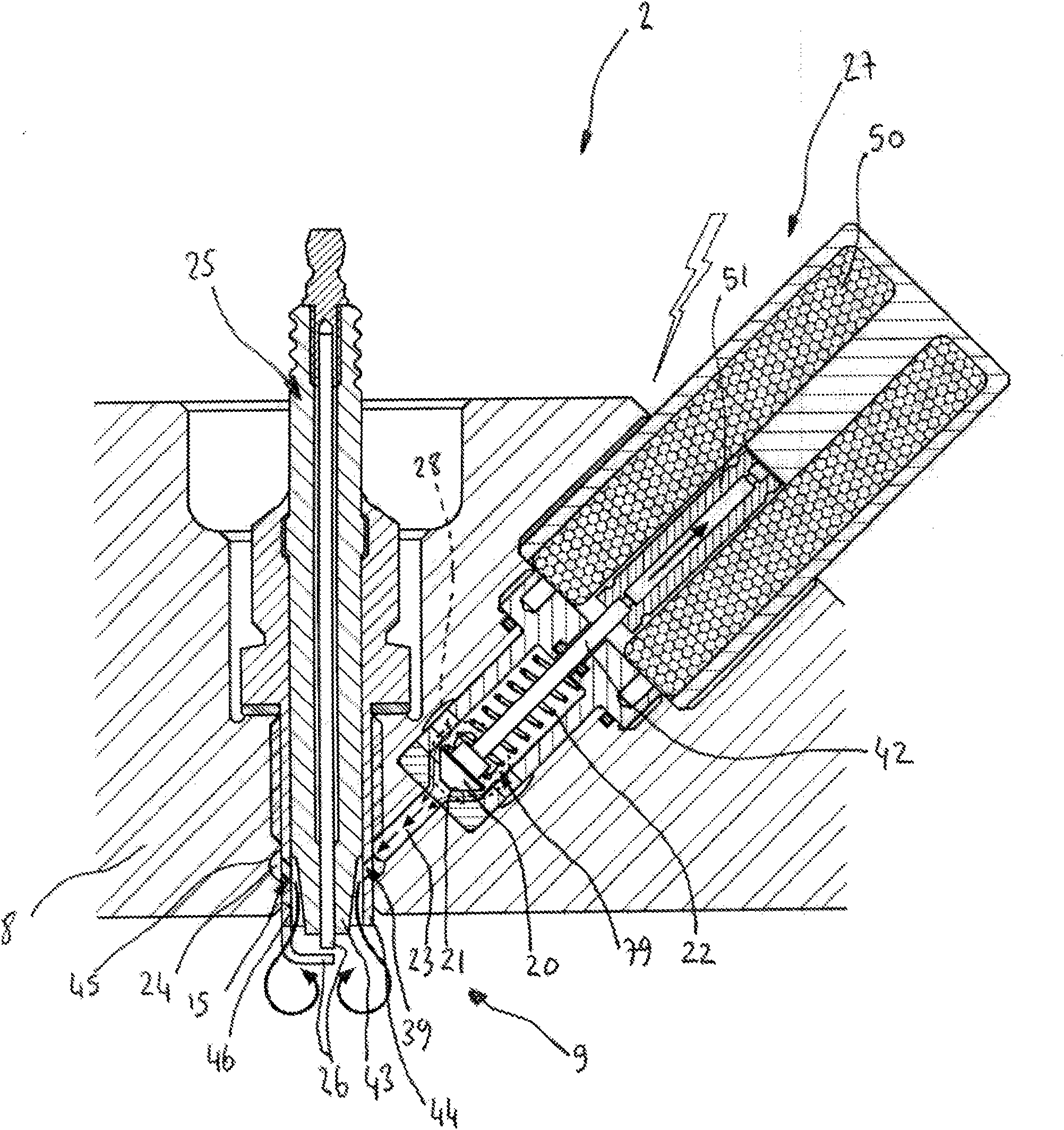

[0111] The cylinder head 8 of the internal combustion engine 1 comprises a combustion chamber 9 into which, on the one hand, there is an intake duct 11 , which may or may not be closed by an intake valve 13 , and which communicates with an intake plenum 19 , and on the other hand , there is an exhaust duct 10 leading therein which may or may not be closed by an exhaust valve 12 and which communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com