Cylinder part welding method and cylinder part welding device

A part welding and welding device technology, applied in the field of welding methods and devices, can solve the problems of difficulty in welding cylindrical parts, inconvenient workpiece clamping, affecting welding quality, etc., and achieves flexible use, adjustable welding speed, Ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

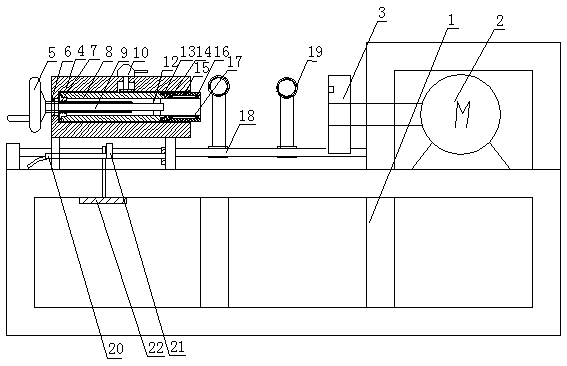

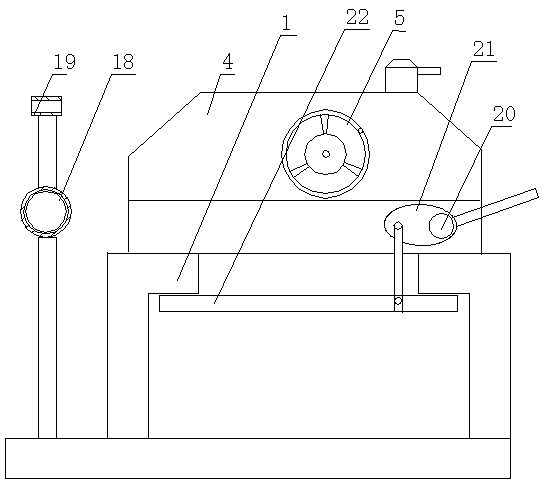

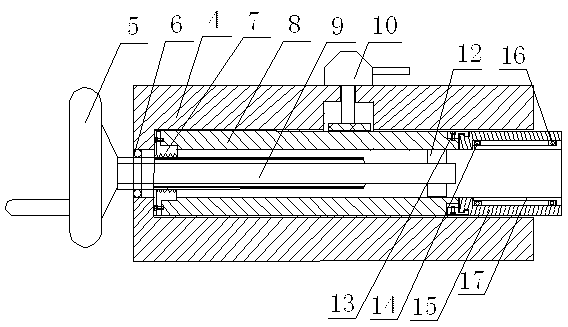

[0025] as attached Figure 1 ~ Figure 3 The welding device for cylindrical parts shown includes a frame 1; a power transmission device 2 connected to the frame 1; a chuck 3 connected to the output shaft of the power transmission device 2; Mechanism; welding torch support 18; two automatic welding torches 19 that are movably connected with welding torch support 18; travel switch 30 that is connected with frame 1 (referring to Figure 4 ). The tail clamping mechanism includes a base 4 that is slidably connected with the guide rail of the frame 1; a first sleeve 8 and a second sleeve 15 that are slidably connected with the axial hole inner wall of the base 4; through the second bearing 14 and the third The bearing 16 is rotatably connected to the inner wall of the axial hole of the second sleeve 15; the first end is connected with the inner hole of the third sleeve 17, and the second end is away from the chuck with the cylindrical part to be welded Top plate for 3-terminal mati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com