Manufacturing technology and equipment for steel lining polyurethane composite tube

A technology of manufacturing equipment and manufacturing process, which is applied in the field of composite pipe manufacturing technology, can solve problems such as lining falling off, thickness deviation cannot be adjusted, and product quality cannot be guaranteed, so as to improve pouring quality, reduce lining falling off, and avoid lining The effect of uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

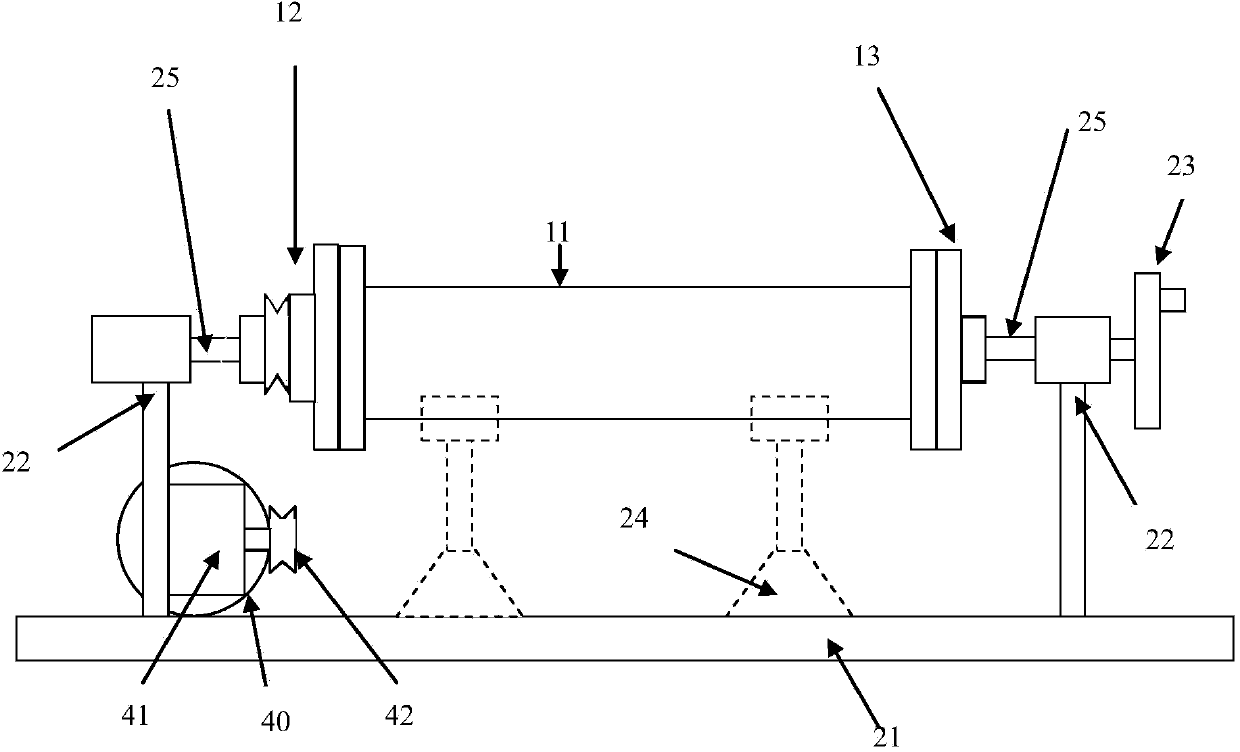

[0034] The present invention will be further described below in conjunction with the drawings.

[0035] The first embodiment of the manufacturing process of the steel-lined polyurethane composite pipe of the present invention:

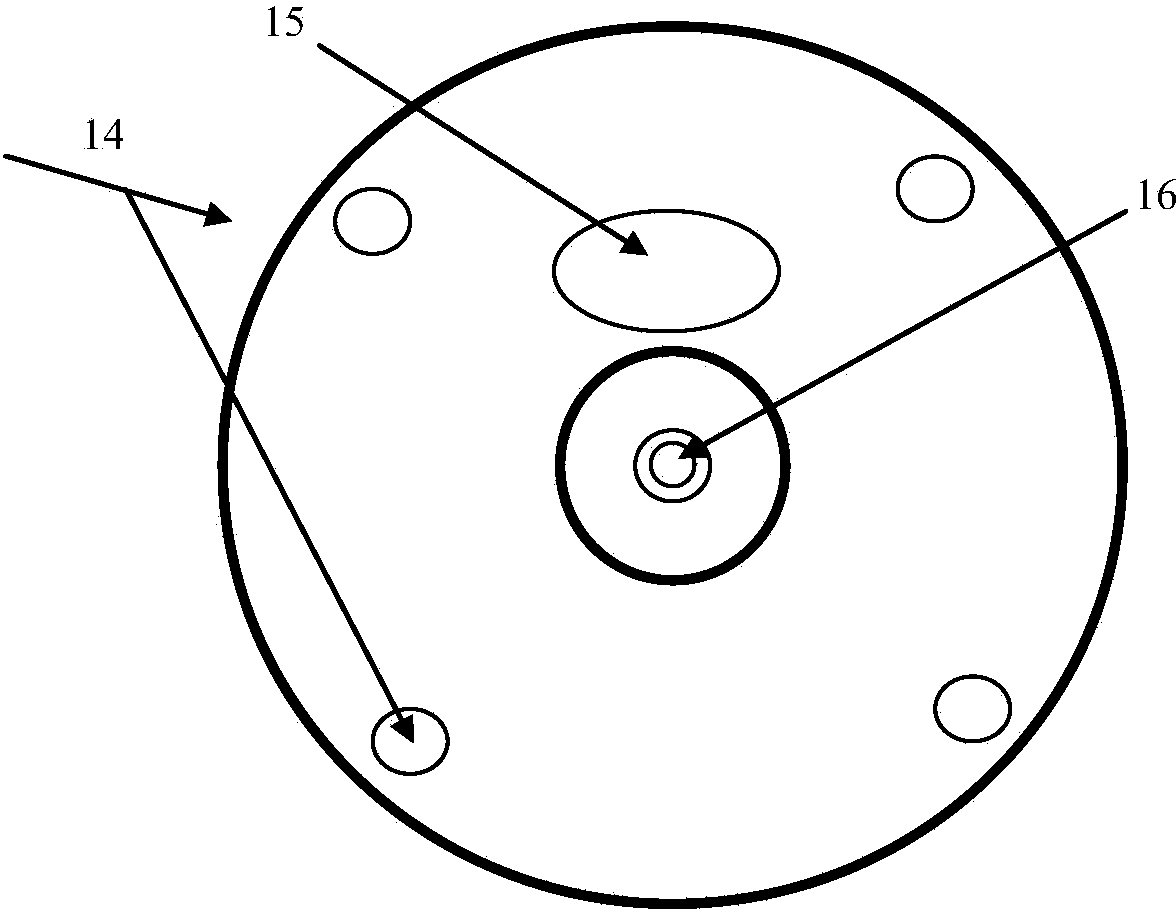

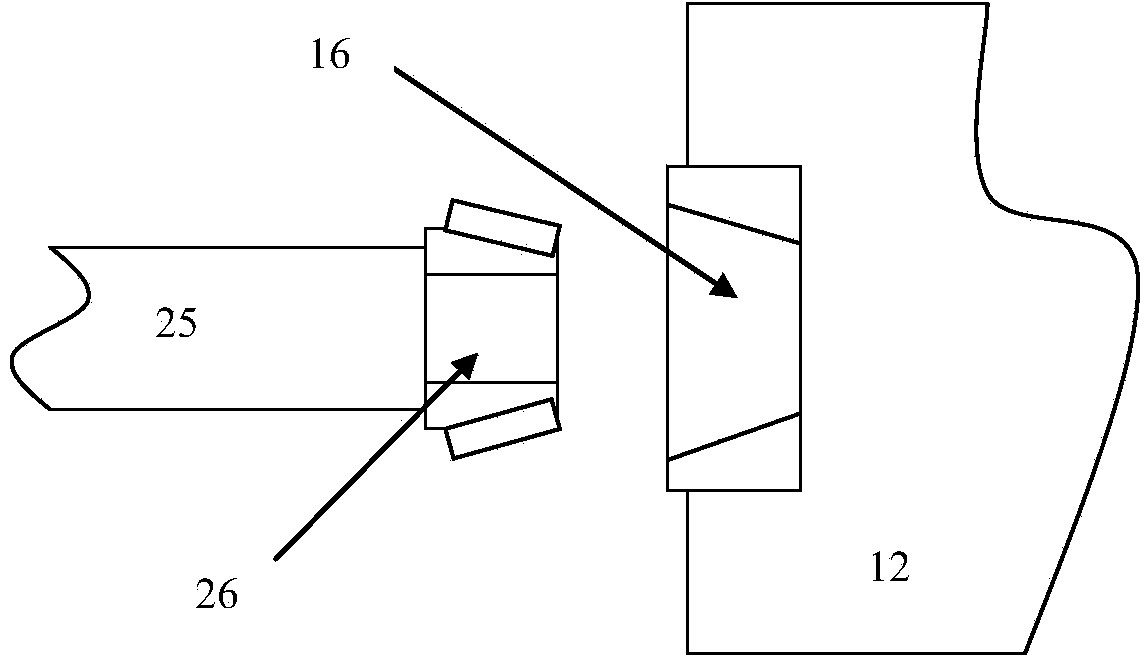

[0036] A. The inner wall of the steel pipe 11 is sandblasted to remove rust. You can use sandblasting, steel brushing, etc. to remove burrs, edges and corners, oil stains, etc. on the steel pipe 11; then apply the polyurethane adhesive evenly and air dry at room temperature 3h or more; then put the steel pipe 11 on the bracket 22, and firmly install the forming tooling mold on the two ends of the steel pipe 11. In order to facilitate the injection process, it is preferable that the pouring ports 15 at both ends of the steel pipe 11 are kept in the same direction;

[0037] B. Weigh the polyurethane prepolymer and polyurethane curing agent Moka according to the mass ratio of 100:12. Heat the polyurethane prepolymer to 60°C to 80°C, and heat the curing agent Mok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com