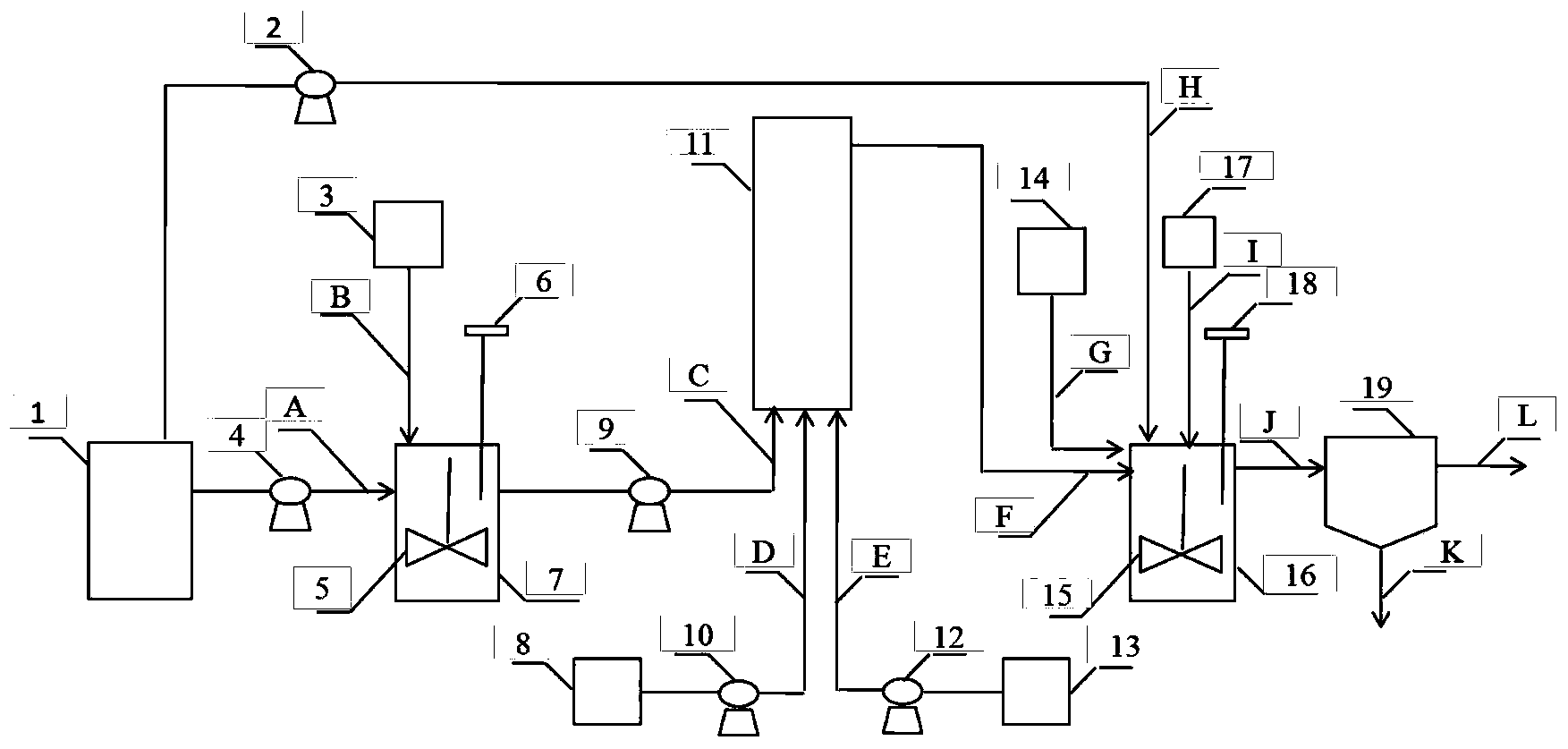

Separated-point inflow type Fenton reagent oxidation treatment device and method for treating wastewater

A technology of oxidation treatment and point-by-point water intake, which is applied in water/sewage treatment, chemical instruments and methods, and wastewater treatment in processing processes, etc., can solve the problems of low utilization rate, improve utilization rate, reduce usage, and increase treatment The effect of water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

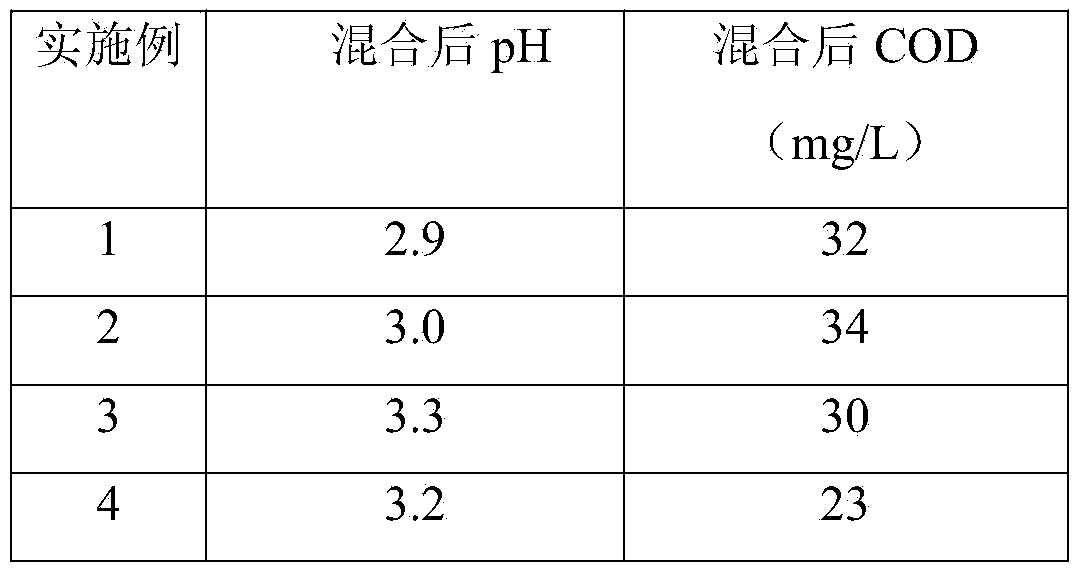

Embodiment 1

[0037] By adjusting the second pump, the waste water flow rate is 10L / h and enters the first pH value adjustment tank; the first pump is adjusted so that the waste water flow rate is 3L / h and enters the second pH value adjustment tank;

[0038] By adjusting the addition of sulfuric acid in the sulfuric acid storage tank to the first pH value adjustment tank, so that the pH value of the first pH value adjustment tank is 4, the hydraulic retention time of waste water is 20min;

[0039] The hydraulic retention time of the fluidized column is 60min, and the ferrous sulfate aqueous solution is stored in the ferrous sulfate solution storage tank, wherein FeSO 4 ·7H 2 The mass percentage of O is 2wt%, and the amount added to the fluidized column is 5LFeSO per ton of waste water 4 ·7H 2 The aqueous solution of O; store hydrogen peroxide in the hydrogen peroxide storage tank, the mass percent of hydrogen peroxide is 30wt%, and in the fluidized column, the addition is 0.2L hydrogen pe...

Embodiment 2

[0044] By adjusting the second pump, the waste water flow rate is 10L / h and enters the first pH value adjustment tank; the first pump is adjusted so that the waste water flow rate is 1L / h and enters the second pH value adjustment tank;

[0045] By adjusting the addition of sulfuric acid in the sulfuric acid storage tank to the first pH value adjustment tank, so that the pH value of the first pH value adjustment tank is 3, the hydraulic retention time of waste water is 15min;

[0046] The hydraulic retention time of the fluidized column is 30min, and the ferrous sulfate aqueous solution is stored in the ferrous sulfate solution storage tank, wherein FeSO 4 ·7H 2 The mass percentage of O is 1wt%, and the amount added to the fluidized column is 1 LFeSO per ton of waste water 4 ·7H 2 The aqueous solution of O; Store hydrogen peroxide (being the aqueous solution of hydrogen peroxide) in the hydrogen peroxide storage tank, the mass percent of hydrogen peroxide is 25wt%, and in flu...

Embodiment 3

[0051] By adjusting the second pump, the waste water flow rate is 20L / h and enters the first pH value adjustment tank; the first pump is adjusted so that the waste water flow rate is 1L / h and enters the second pH value adjustment tank;

[0052] By adjusting the addition of sulfuric acid in the sulfuric acid storage tank to the first pH value adjustment tank, so that the pH value of the first pH value adjustment tank is 3.5, the hydraulic retention time of waste water is 20min;

[0053] The hydraulic retention time of the fluidized column is 40min, and the ferrous sulfate aqueous solution is stored in the ferrous sulfate solution storage tank, wherein FeSO 4 ·7H 2 The mass percentage of O is 1.5wt%, and the amount added to the fluidized column is 3LFeSO per ton of waste water 4 ·7H 2 The aqueous solution of O; Store hydrogen peroxide (being the aqueous solution of hydrogen peroxide) in the hydrogen peroxide storage tank, the mass percent of hydrogen peroxide is 28wt%, and in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com