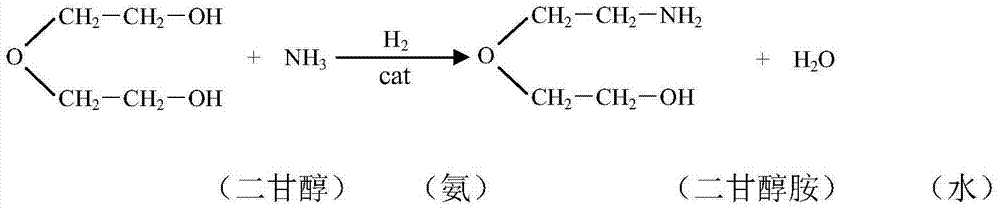

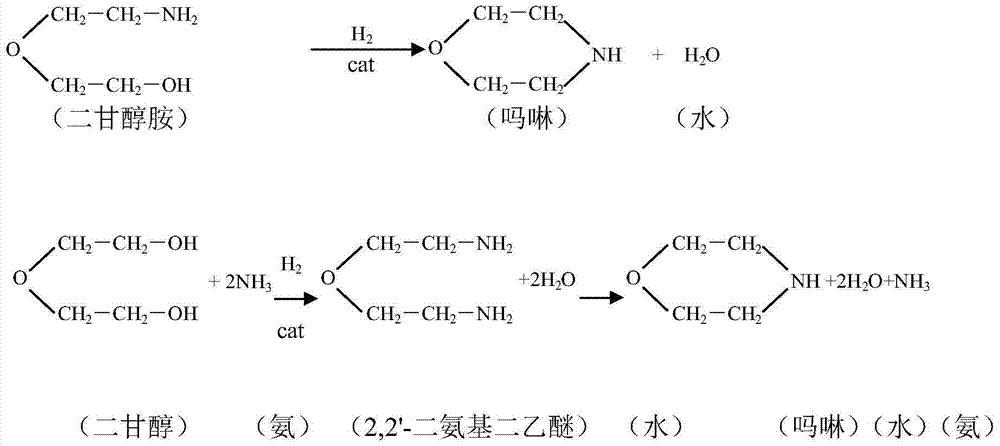

Method for synthesizing diglycolamine from diglycol by virtue of low-pressure process

A technology of diethylene glycol amine and diethylene glycol is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc. The effect of high content and few side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

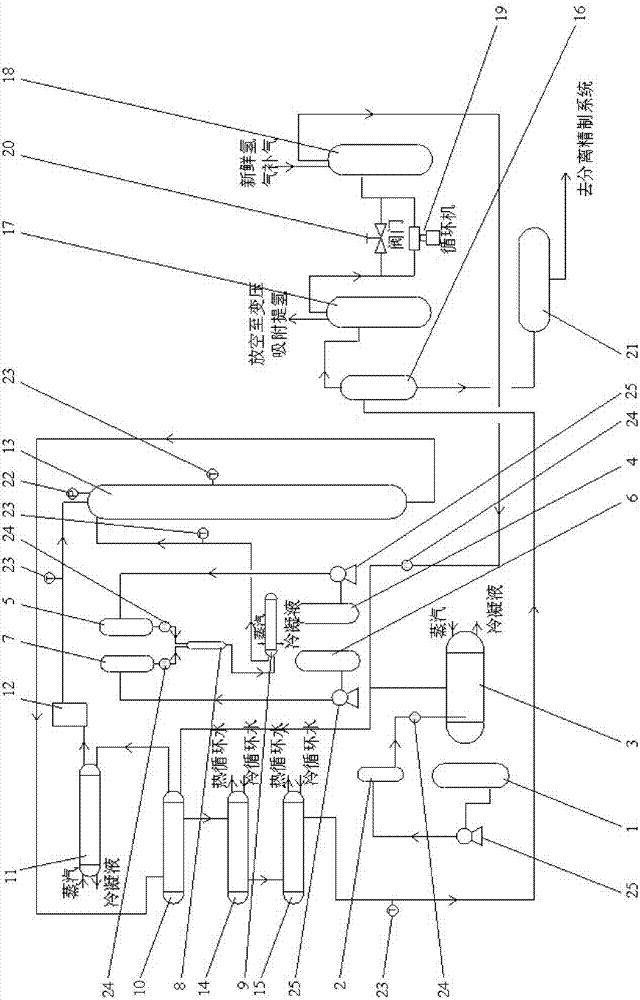

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] Such as figure 1 As shown, before the reaction feed, the air in the reactor 13 is first replaced with nitrogen, and then the preheated hydrogen is continuously passed into the reactor 13, so that the temperature of the catalyst in the reactor 13 is raised to 180-240 ° C, and the reactor 13 The pressure is raised to 1.60-1.75MPa, and when the temperature of the catalyst and the pressure in the tower rise to the reaction temperature and pressure, the hydrogen circulation is stopped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com