Flame-retardant polyurethane rigid foam taking melamine as basic characteristic and preparation method of flame-retardant polyurethane rigid foam

A melamine and rigid foam technology, applied in the field of polyurethane flame retardant materials, can solve the problems of unsustainable flame retardant effect, high production cost and easy migration of structural flame retardant foam, and achieve the effect of good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

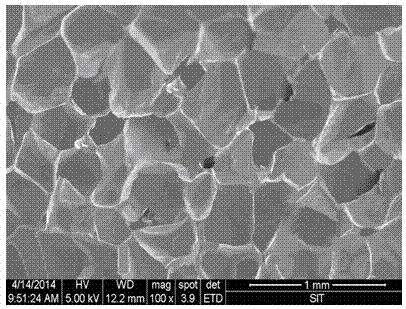

Image

Examples

Embodiment 1

[0044] A flame-retardant polyurethane rigid foam based on melamine, consisting of component A and component B, the weight ratio of component A and component B is 1:1.4;

[0045] The A component described therein is calculated in parts by weight, and its raw material composition and content are as follows:

[0046] 22.5 parts of flame-retardant polyether polyol with melamine as the basic structure

[0047] Catalyst 1.5 parts

[0048] Foam stabilizer 0.8 parts

[0049] Physical foaming agent 2.0 parts

[0050] 1.5 parts of water;

[0051] Wherein said catalyst is triethylenediamine;

[0052] Described foam stabilizer is silicone oil;

[0053] The physical blowing agent is HCFC-141b;

[0054] The flame-retardant polyether polyol with melamine as the basic structure is calculated in parts by weight, and its raw material composition and content are as follows:

[0055] 7.5 parts of melamine

[0056] Formaldehyde 15 parts

[0057] Alkaline conditioner 0.05 parts

[0058] Co-...

Embodiment 2

[0075] A flame-retardant polyurethane rigid foam based on melamine, consisting of component A and component B, the weight ratio of component A and component B is 1:1.3;

[0076] The A component described therein is calculated in parts by weight, and its raw material composition and content are as follows:

[0077] 22.5 parts of flame-retardant polyether polyol with melamine as the basic structure

[0078] Catalyst 1.0 parts

[0079] Foam stabilizer 0.9 parts

[0080] Physical foaming agent 2.5 parts

[0081] 2.0 parts of water;

[0082] Wherein said catalyst is N, N-dimethylcyclohexane;

[0083] Described foam stabilizer is silicon carbon type stabilizer;

[0084] The physical foaming agent is a mixture of HCFC-141b and cyclopentane in mass ratio, that is, HCFC-141b: cyclopentane is 1:1.5;

[0085] The flame-retardant polyether polyol with melamine as the basic structure is calculated in parts by weight, and its raw material composition and content are as follows:

[00...

Embodiment 3

[0105] A flame-retardant polyurethane rigid foam based on melamine, consisting of component A and component B, the weight ratio of component A and component B is 1:1.1;

[0106] The A component described therein is calculated in parts by weight, and its raw material composition and content are as follows:

[0107] 22.5 parts of flame-retardant polyether polyol with melamine as the basic structure

[0108] Catalyst 1.2 parts

[0109] Foam stabilizer 0.8 parts

[0110] Physical blowing agent 2 parts

[0111] 1 part of water;

[0112] Wherein said catalyst is tetramethylethylenediamine;

[0113] The foam stabilizer is a mixture of silicone oil and silicon carbon stabilizer in a mass ratio of 1:1;

[0114]Described physical blowing agent is HFC-245fa;

[0115] The flame-retardant polyether polyol with melamine as the basic structure is calculated in parts by weight, and its raw material composition and content are as follows:

[0116] Melamine 5.0 parts

[0117] Formaldehy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com