Composite modified asphalt

A technology of compound modified asphalt and modified asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of not being able to meet road performance at the same time, not being very compatible, and having different functions and prices. Good economic benefits, improve compatibility, reduce the effect of release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

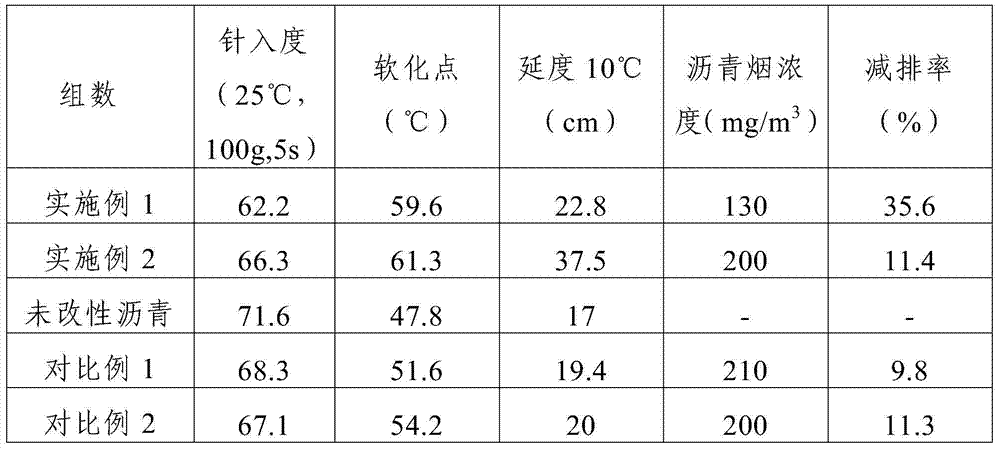

Examples

Embodiment 1

[0024] The composite modified asphalt in this example is made from the following raw materials in parts by weight: 100 parts of asphalt, 7.6 parts of epidote powder, 7.3 parts of rhyolite powder, 1.3 parts of zotinite powder, γ-aminopropyltriethoxysilane 1.2 parts, 0.5 part of dibutyltin diacetate, 0.5 part of dispersant; Described asphalt is preferably matrix asphalt, SBS modified asphalt, SBR modified asphalt or natural rubber modified asphalt, what the present embodiment adopted is matrix asphalt; Described The dispersant is preferably one or more of sodium polymethacrylate, sodium tripolyphosphate, sodium hexametaphosphate and sodium polyacrylate. What this embodiment uses are sodium tripolyphosphate, sodium hexametaphosphate and polyacrylic acid Sodium is mixed uniformly at a mass ratio of 0.5:1:2.

[0025] The preparation method of the present embodiment composite modified asphalt comprises the following steps:

[0026] Step 1, mixing the epidote powder, the rhyolite po...

Embodiment 2

[0031] The composite modified asphalt in this example is made from the following raw materials in parts by weight: 100 parts of asphalt, 3 parts of epidote powder, 3 parts of rhyolite powder, 0.1 part of zotinite powder, γ-aminopropyltriethoxysilane 0.1 part, 0.1 part of dibutyltin diacetate; the asphalt is preferably base asphalt, SBS modified asphalt, SBR modified asphalt or natural rubber modified asphalt, and the present embodiment uses base asphalt.

[0032] The preparation method of the present embodiment composite modified asphalt comprises the following steps:

[0033] Step 1, mixing the epidote powder, the rhyolite powder and the zeolite powder evenly to obtain a mixture 1;

[0034] Step 2, prepare the ethanol solution of γ-aminopropyl triethoxysilane with the ethanol solution of 30% ethanol with mass percent concentration, then join mixture one and dibutyltin diacetate to the γ-aminopropyl triethoxysilane In the ethanol solution, stir evenly and soak for 1 hour to o...

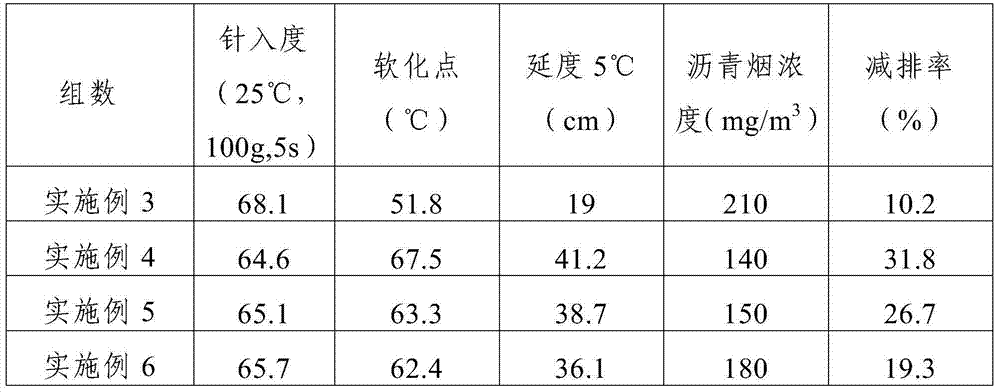

Embodiment 3

[0038] The composite modified asphalt in this example is made from the following raw materials in parts by weight: 100 parts of asphalt, 5 parts of epidote powder, 5 parts of rhyolite powder, 0.5 part of zotinite powder, γ-aminopropyltriethoxysilane 0.5 part, 0.3 part of dibutyltin diacetate, and 0.3 part of dispersant; the asphalt is preferably base asphalt, SBS modified asphalt, SBR modified asphalt or natural rubber modified asphalt, and what this embodiment uses is SBS modified asphalt; The dispersant is preferably one or more of sodium polymethacrylate, sodium tripolyphosphate, sodium hexametaphosphate and sodium polyacrylate. What this embodiment uses is sodium hexametaphosphate and sodium polyacrylate. A mixture made by mixing evenly at a ratio of 1:1.

[0039] The preparation method of the present embodiment composite modified asphalt comprises the following steps:

[0040] Step 1, mixing the epidote powder, the rhyolite powder and the zeolite powder evenly to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com