Method for preparing graphene from raw graphite ores through electrolysis

A graphene and electrolysis technology, applied in electrolysis process, electrolysis components, etc., can solve undiscovered problems and achieve high-efficiency preparation, high yield, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

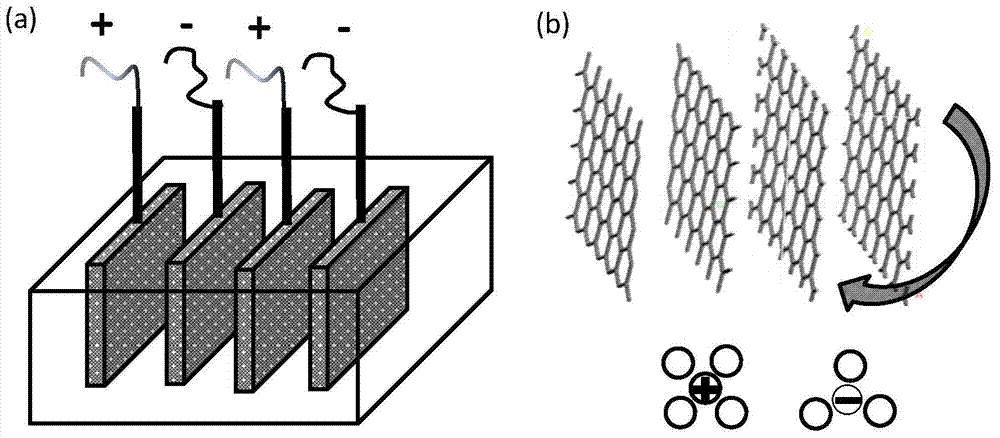

Method used

Image

Examples

Embodiment 1

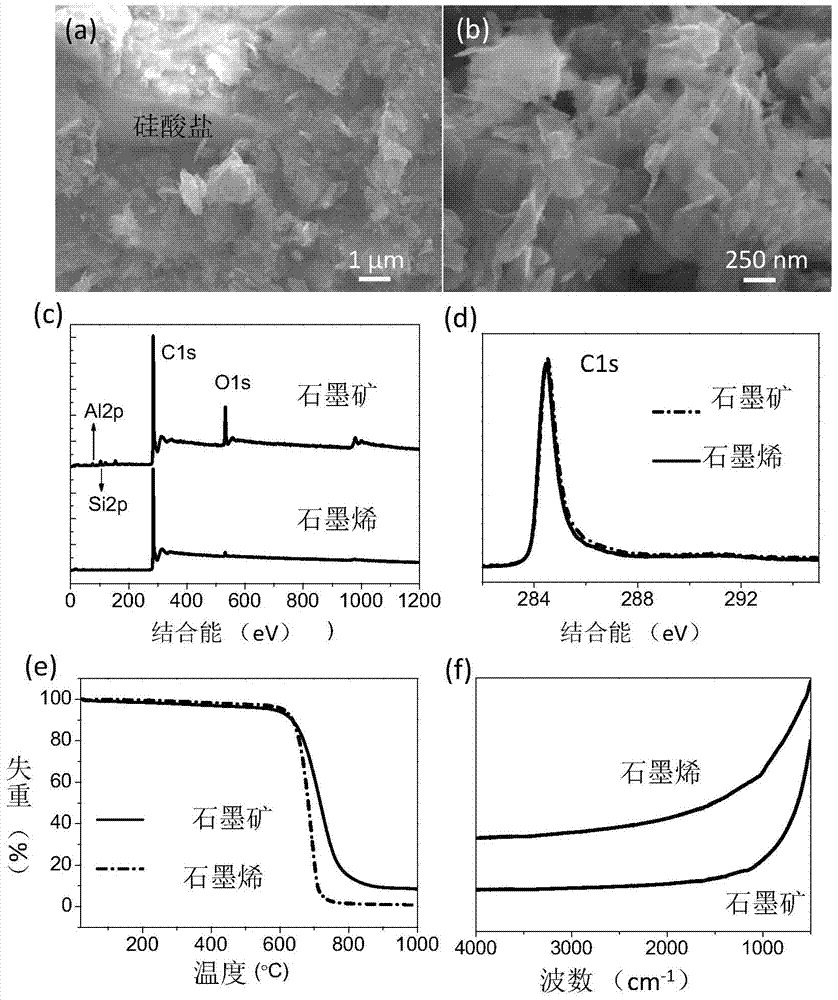

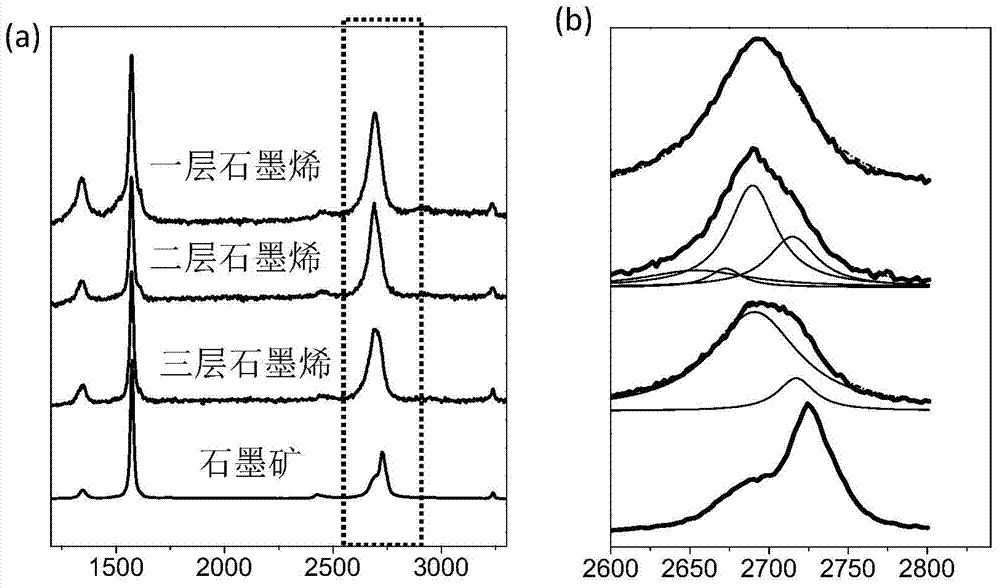

[0089] (1) 50.0g diameter is the agate ball milling ball of 1-1.3cm, 1.0g microcrystalline graphite ore and 80ml dispersant are sealed in the agate ball mill jar under argon protection, then the ball mill jar is placed on the planetary ball mill and Ball mill at 580rpm for 2 hours. Remove the agate ball with tweezers. Dispersant is 70wt% HClO 4 Aqueous solution, the ratio of dispersant and microcrystalline graphite raw ore raw material is 80ml / g. The average particle size of microcrystalline graphite raw ore after ball milling is 30 μm. (2) Put the raw ore powder of microcrystalline graphite directly into polyethylene bags after ball milling to make anodes and cathodes. The distance between the anode and cathode was 5 mm, and the average pore size of the polyethylene bag was 0.2 μm. (3) Apply a DC voltage of +5V to -5V between the anode and the cathode, electrolyze for 120 hours, exchange the electrodes every 10 hours, and control the electrolysis temperature at 25°C. The...

Embodiment 2

[0091] (1) 50.0g diameter is the agate ball milling ball of 1-1.3cm, 1.0g microcrystalline graphite raw ore and 80ml dispersant are sealed in the agate ball mill jar under argon protection, then the ball mill jar is placed on the planetary ball mill and Ball mill at 580rpm for 2 hours. Remove the agate ball with tweezers. The dispersant is 10wt% H 2 SO 4 Aqueous solution, the ratio of dispersant and microcrystalline graphite raw ore raw material is 80ml / g. The average particle size of microcrystalline graphite raw ore after ball milling is 30 μm. (2) Put the raw ore powder of microcrystalline graphite directly into polyethylene bags after ball milling to make anodes and cathodes. The distance between the anode and cathode was 5 mm, and the average pore size of the polyethylene bag was 0.2 μm. (3) Apply a DC voltage of +8V to -8V between the anode and the cathode, electrolyze for 60 hours, exchange the electrodes every 3 hours, and control the electrolysis temperature at 4...

Embodiment 3

[0093] (1) 50.0g diameter is the agate ball milling ball of 1-1.3cm, 1.0g microcrystalline graphite raw ore and 80ml dispersant are sealed in the agate ball mill jar under argon protection, then the ball mill jar is placed on the planetary ball mill and Ball mill at 580rpm for 2 hours. Remove the agate ball with tweezers. Dispersant is 35wt% HNO 3 Aqueous solution, the ratio of dispersant and microcrystalline graphite raw ore raw material is 80ml / g. The average particle size of microcrystalline graphite raw ore after ball milling is 30 μm. (2) Put the raw ore powder of microcrystalline graphite directly into polyethylene bags after ball milling to make anodes and cathodes. The distance between the anode and cathode was 5 mm, and the average pore size of the polyethylene bag was 0.2 μm. (3) Apply a DC voltage of +10V to -10V between the anode and the cathode, electrolyze for 4 hours, exchange the electrodes every 30 minutes, and control the electrolysis temperature at 60°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com