Richcel fiber-silk jean and weaving method thereof

A technology of Lisa fiber and denim, which is applied in the field of clothing production, to achieve the effects of good drapability, improved dyeing uniformity, and soft and waxy hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The warp yarn adopts the blended yarn of Lisa fiber and silk fiber with a mixing ratio of 50:50, that is, in the warp yarn, Lisa fiber accounts for 50% of the warp yarn proportion, and silk fiber accounts for 50% of the warp yarn proportion; the weft yarn adopts cotton-spandex blended yarn RSB12S / 20D; Warp and weft density: 400×260 threads / 10cm; Width: 150cm. Warp shrinkage≦-2.0% Weft shrinkage≦-5.0%.

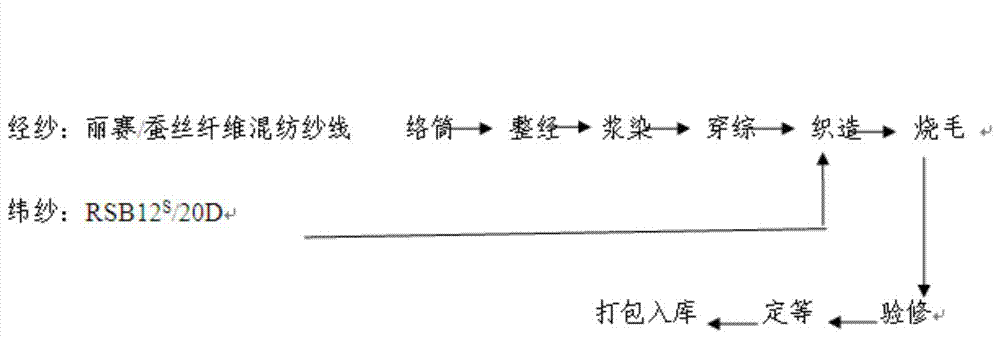

[0033] In the weaving method of Lisai fiber and silk fiber denim in this embodiment, the weaving process is formed by interweaving warp yarns and weft yarns. The package yarn enters the weaving process with the warp yarn after being twisted; the main production process points are:

[0034] In the winding process, the loose winding machine generally adopts a line speed of 850m / min. The pressure of the loose package arm is selected at 2-3N overfeeding, which compensates the tension change caused by the annoying unwinding of the feeding package. Overfeed rollers work th...

Embodiment 2

[0042] The warp yarn is made of Lisa fiber and silk fiber blended yarn with a mixing ratio of 40:60, that is, in the warp yarn, Lisa fiber accounts for 40% of the warp yarn proportion, silk fiber accounts for 60% of the warp yarn proportion, and the weft yarn adopts cotton-spandex blended yarn RSB12 S / 20D; Warp and weft density: 400×260 threads / 10cm; Width: 150cm. The weaving method is the same as in Example 1, the modifier uses polyglycidyl ether, and the shrinkage in the warp direction is ≦-2.0% and the shrinkage in the weft direction is ≦-5.0%.

Embodiment 3

[0044] The warp yarn is made of Lisa fiber and silk fiber blended yarn with a mixing ratio of 60:40, that is, in the warp yarn, Lisa fiber accounts for 60% of the warp yarn proportion, silk fiber accounts for 40% of the warp yarn proportion, and the weft yarn adopts cotton-spandex blended yarn RSB12S / 20D; Warp and weft density: 400×260 threads / 10cm; Width: 150cm. The weaving method is the same as that in Example 1, glycerol diglycidyl ether is used as the modifier, and the shrinkage in the warp direction is ≦-2.0% and the shrinkage in the weft direction is ≦-5.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com