Surface embedded bar reinforced prestress tension method and device

A tensioning device and prestressing technology, which is applied in bridge reinforcement, building material processing, erection/assembly of bridges, etc., can solve the problems that embedded reinforcement bars cannot pass through, and cannot provide tensioning device installation and operation space, etc. Achieve the effect of simple structure, simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

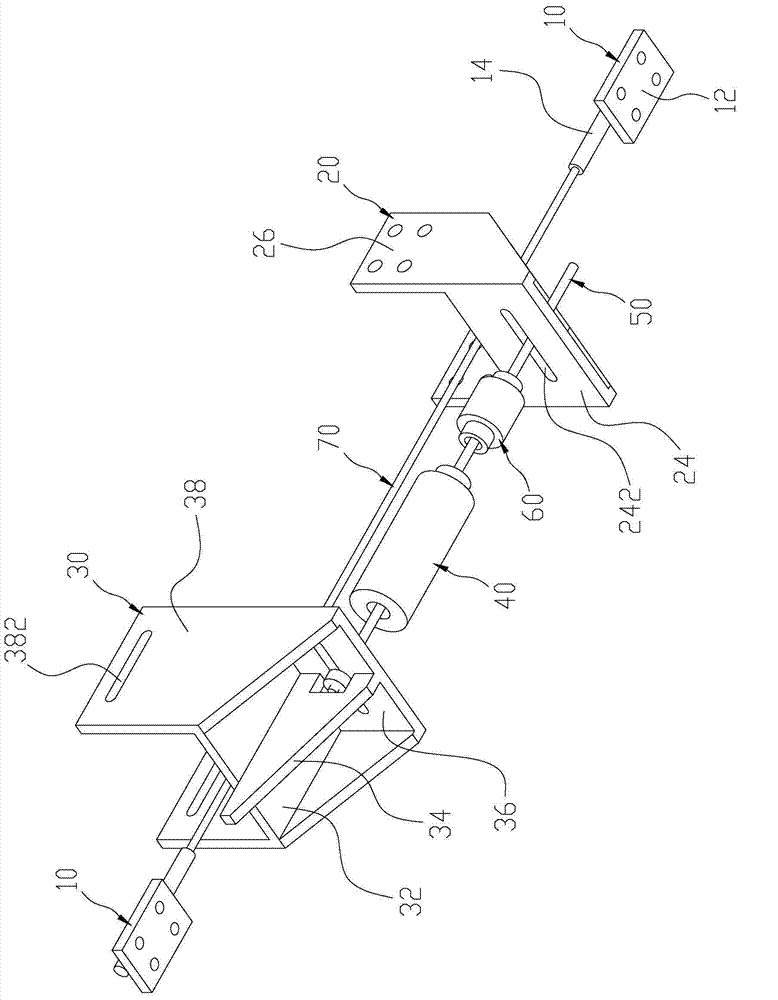

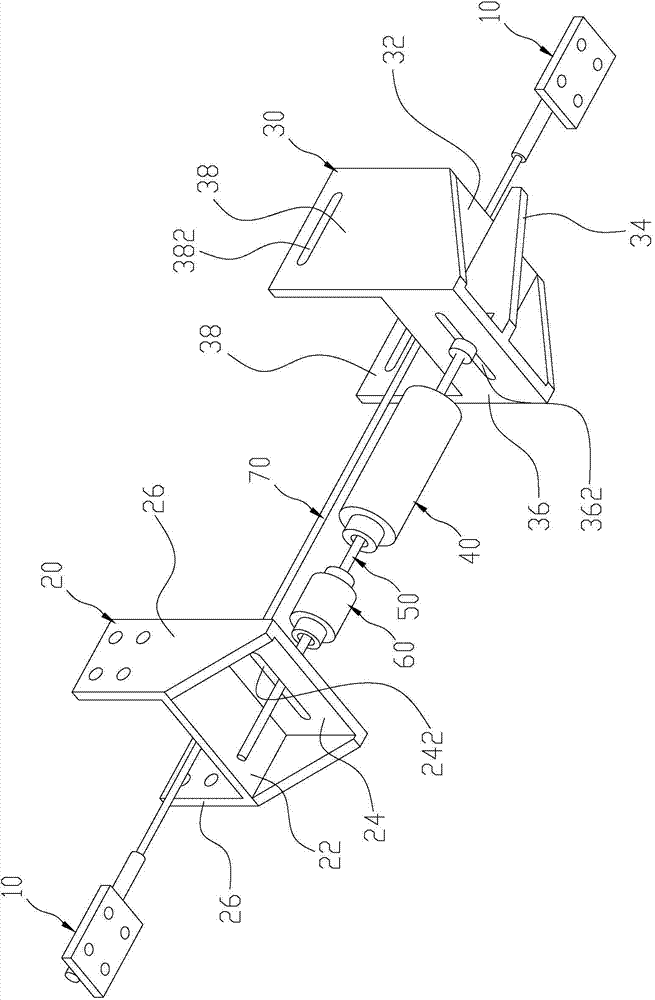

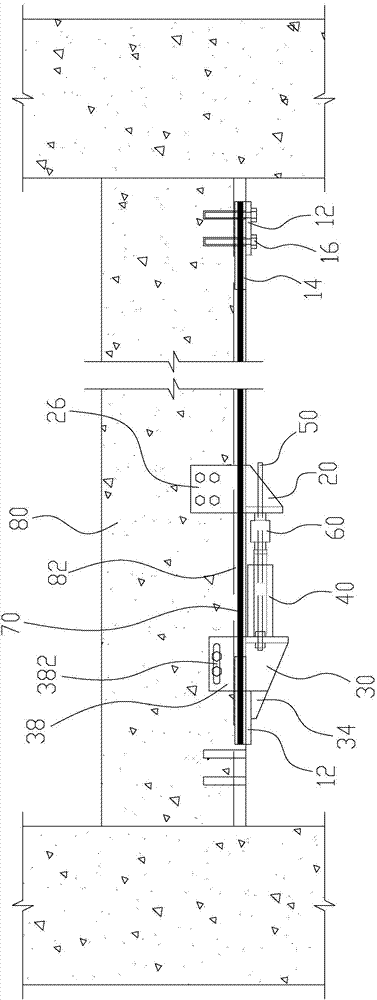

[0032] Please refer to figure 1 and figure 2 , a prestressed tensioning device for reinforcement of surface reinforcement of the present invention, comprising: two sleeve steel plate anchors 10, a fixed tensioning base 20, a mobile tensioning base 30, an expansion device 40, a positioning screw 50, a force sensor 60. Two sleeve steel plate anchors 10 are respectively connected to the two ends of the reinforcing bar 70; the fixed tensioning base 20 and the mobile tensioning base 30 are arranged between the two sleeve steel plate anchors 10; the positioning screw 50 is connected to the fixed tensioning Between the pedestal 20 and the mobile tensioning pedestal 30 ; the expansion device 40 is arranged on the positioning screw 50 and connected between the fixed tensioning pedestal 20 and the mobile tensioning pedestal 30 ; the force sensor 60 is arranged on the positioning screw 50 .

[0033] The sleeve steel plate anchor 10 includes a steel plate 12 and a steel sleeve 14 . Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap