Thermal energy comprehensive recycling method applied to viscose staple fibre waste water

A technology of viscose staple fiber and thermal energy, which is applied in the thermal energy recovery and utilization of waste water in the production of viscose staple fiber, and in the field of comprehensive thermal energy recycling. Good social benefits and economic value, prevent the reduction of heat exchange effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

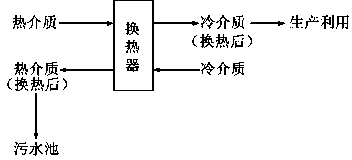

[0041] The present invention relates to a heat energy comprehensive recycling method suitable for viscose staple fiber waste water. The method is a heat exchange treatment of waste water in the production of viscose staple fiber. In the existing technology, the waste heat of the overflow water of the plasticizing tank is usually adopted such as figure 1 The heat exchange process shown is for processing. The temperature of the plasticizing tank overflow water from the plasticizing tank is 90-95°C. After simple heat exchange, the overflow water of the plasticizing tank still has residual heat, and the temperature is 70-80°C. , that is, it is discharged to the sewage station for treatment, and its heat energy has not been fully utilized. Therefore, this embodiment adopts the following heat transfer process, that is, the overflow water of the plasticizing tank is subjected to step-by-step heat transfer, and the step-by-step heat transfer method is adopted. The heating medium in th...

Embodiment 2

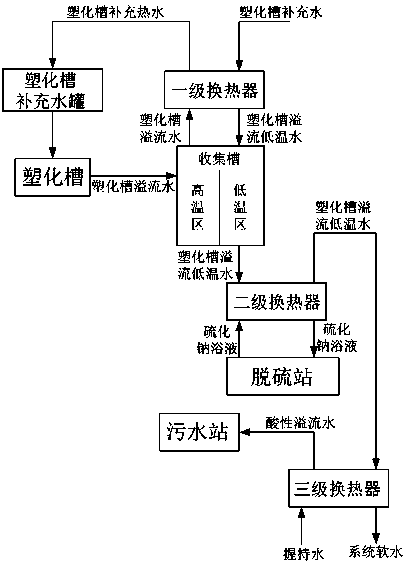

[0043] The difference between this embodiment and Embodiment 1 is that in this embodiment, the step-by-step heat exchange of the plasticizing tank overflow water includes the step-by-step heat exchange of the plasticizing tank replenishment water, sodium sulfide bath liquid and holding water, which The processing steps are as follows:

[0044] A: Set up a primary heat exchanger, respectively send the overflow water of the plasticizing tank and the supplementary water of the plasticizing tank to the primary heat exchanger for heat exchange treatment. After the heat exchange treatment, the obtained plasticizing tank supplementary hot water is sent to The plasticizing tank, the overflow low-temperature water obtained from the plasticizing tank is sent to the secondary heat exchanger to complete the operation of step B;

[0045] B: Send the sodium sulfide bath liquid from the desulfurization station to the secondary heat exchanger, and use the overflow low-temperature water from t...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that in this embodiment, the step-by-step heat exchange of the plasticizing tank overflow water includes the step-by-step heat exchange of the plasticizing tank replenishment water, sodium sulfide bath liquid and holding water, and at the same time , There is a collection tank connected to the plasticizing tank, and its interior is separated into two partitions by an overflow plate, which are high temperature zone and low temperature zone.

[0049] The treatment steps of the plasticizing tank overflow water involved in this embodiment include:

[0050] (1) The plasticizing tank overflow water in the plasticizing tank overflows to the high temperature zone of the collection tank, and the temperature of the plasticizing tank overflow water is 95°C;

[0051] (2) The overflow water of the plasticizing tank with a temperature of 95°C in the high temperature zone and the replenishment water of the plasticizing tank wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com