A sealing treatment method for biogas digester gas chamber construction

A treatment method and a biogas digester technology are applied in the field of construction and sealing treatment of a biogas digester gas chamber, which can solve the problems of high cost, poor sealing performance of a layer of glass fiber, difficult operation, etc., and achieves easy application, promotion of ecological agriculture development, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

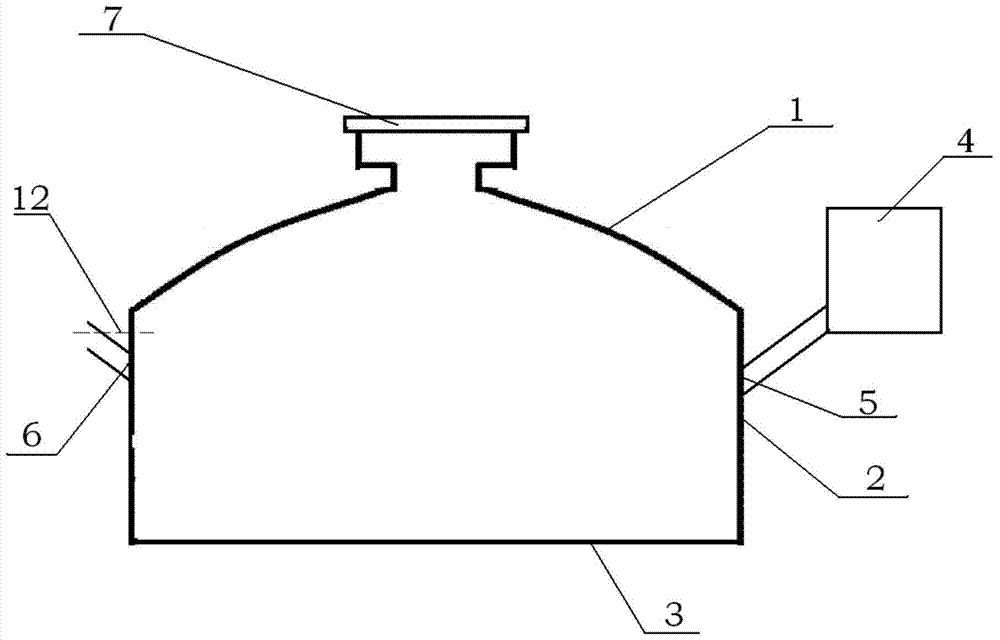

[0051] A method for sealing the gas chamber of a biogas digester. The biogas digester includes a pond bottom, a pond wall, a vault, a water pressure room, a feed pipe, and a discharge pipe. The bottom of the pond, the pond wall and the vault form a fermentation chamber and an air chamber. There is a main pool mouth on the top, a movable cover at the main pool mouth, and an air outlet pipe on the movable cover. The construction and sealing methods include:

[0052] (1) The construction and sealing method for the pool bottom, pool wall, water pressure room, discharge pipe, and feed pipe is: build a layer of brick molds on the pool bottom, pool wall, and water pressure room, and use concrete to The pool body is poured, one layer is poured, and the second layer of brick mold is built after vibrating and compacted. After the material is solidified, the brick mold is removed, and the inner wall of the pool bottom, pool wall, water pressure room, discharge pipe, and feed pipe is inspe...

Embodiment 2

[0060] A biogas digester gas chamber construction sealing treatment method, the method is as described in Example 1, the difference is that it also includes step (4), the biogas digester is tested for sealing.

Embodiment 3

[0062] A biogas digester gas chamber construction sealing treatment method, the method is as described in embodiment 1, the difference is that in step (1) on the bottom of the pond, the wall, the water pressure room, the outlet pipe, and the feed pipe Internal sealing treatment of the inner wall of the part: (a) plastering of the bottom layer: mix and mix cement:sand:water=1:2.5:1 according to the mass ratio to make cement sand mortar, and the brushing thickness is 1cm; (b) Surface layer plastering: mix cement:sand:water=1:1:0.5 according to the mass ratio and mix well to obtain cement sand mortar, and the thickness of brushing is 0.4cm; it must be smoothed and calendered repeatedly, and no blisters can appear; ( c) Brushing mortar on the surface: mix cement: water = 2: 1 according to the mass ratio and mix to obtain a plain mortar, and brush it for 3 times in total. The time interval between each brushing is 4 hours, and the thickness of each brushing is 0.1cm ; Between step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com