A Lens-Type Simulation Device for Heating Surfaces with High Heat Flux

A technology of high heat flux density and heating surface, applied in measuring devices, instruments, etc., can solve the problems of inaccessible heating surface with high heat flux density, large thermal resistance between heating block and heat exchange surface, inaccurate calculation of heat flux density, etc. High density, no contact thermal resistance, uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

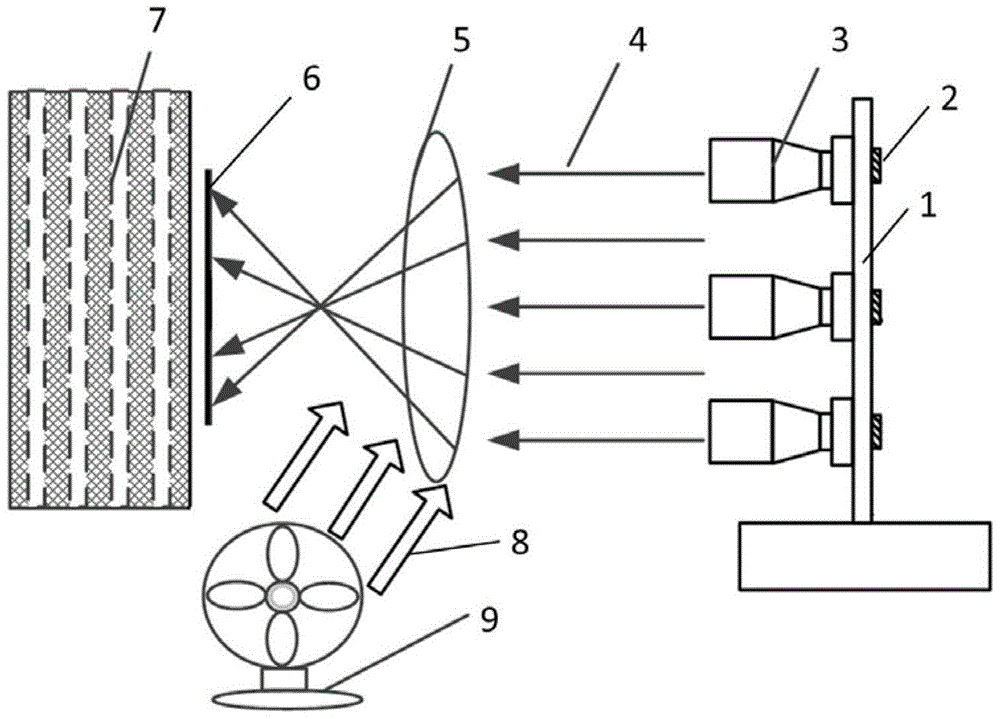

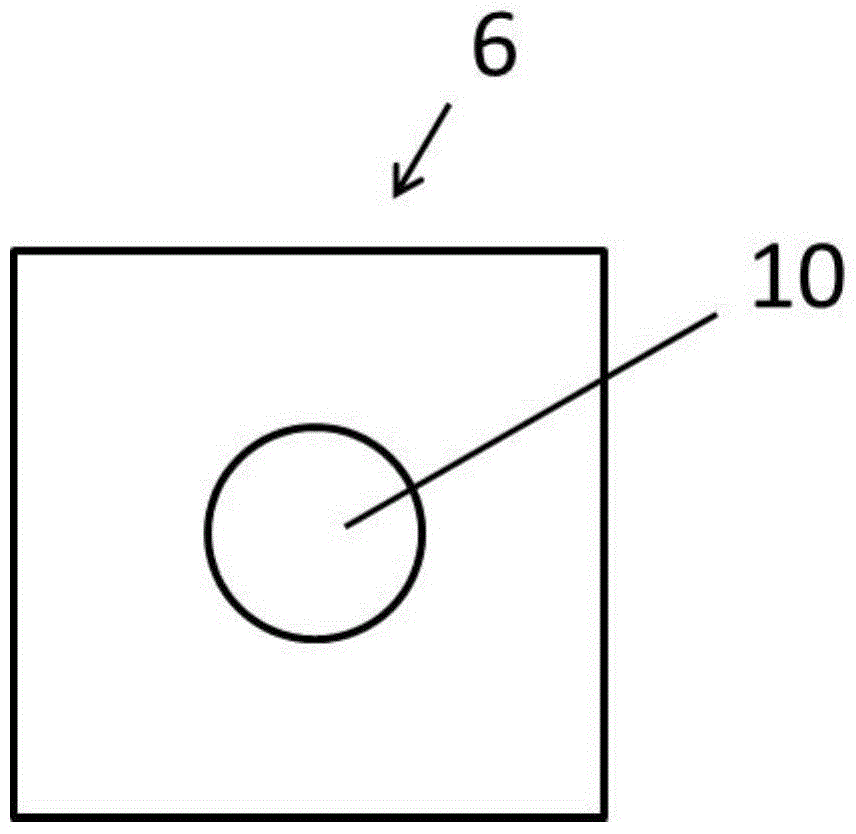

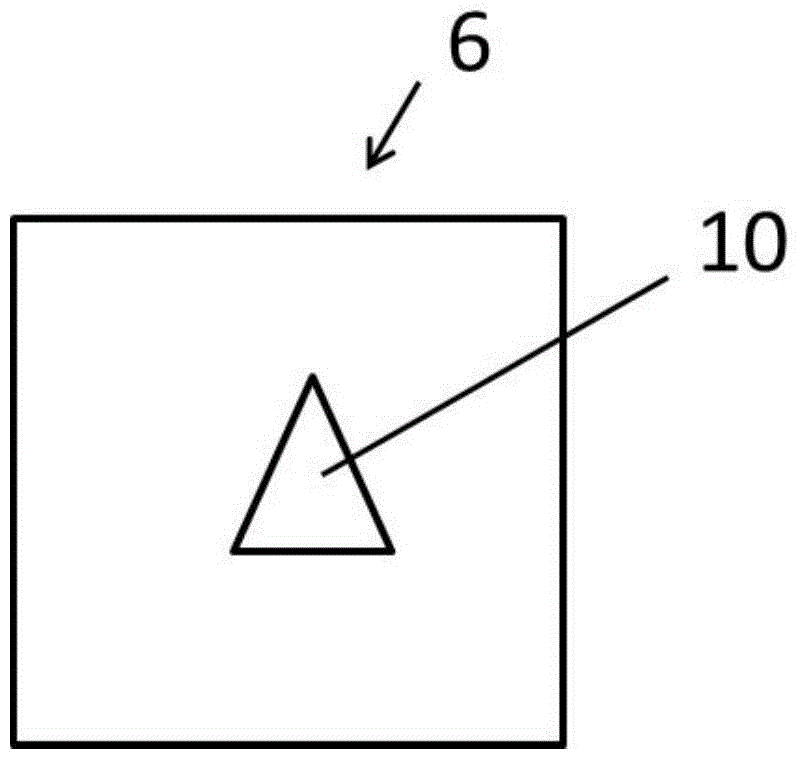

[0022] Such as Figure 1 to Figure 5 As shown, a preferred embodiment of the present invention provides a lens-type simulation device for heating a surface with high heat flux, and its structure includes a fixed component 1 , a parallel light generator 3 , a convex lens 5 and a cooler 7 . Among them, the parallel light generator 3 is installed on the fixed part 1, and the parallel light generator 3 is composed of a group of parallel light source arrays for emitting parallel light 4. The parallel light 4 has a low energy flux density; A convex lens 5 , a shading plate 6 and a cooler 7 are provided, and a light-transmitting hole 10 is provided in the center of the shading plate 6 . The convex lens 5 can make the parallel light 4 with the low energy flux density pass through the light transmission hole 10 on the shading plate 6 to form a high heat flux heating surface on the surface of the cooler 7, and the shading plate 6 has the shape of adjusting the converging light beam to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com