Sample automatic-treatment system

An automatic processing and sample pretreatment technology, applied in the preparation of test samples, analysis materials, instruments, etc., can solve the problems of high labor intensity, low packing efficiency, time-consuming and labor-intensive, etc., and achieve the effect of high liquid extraction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

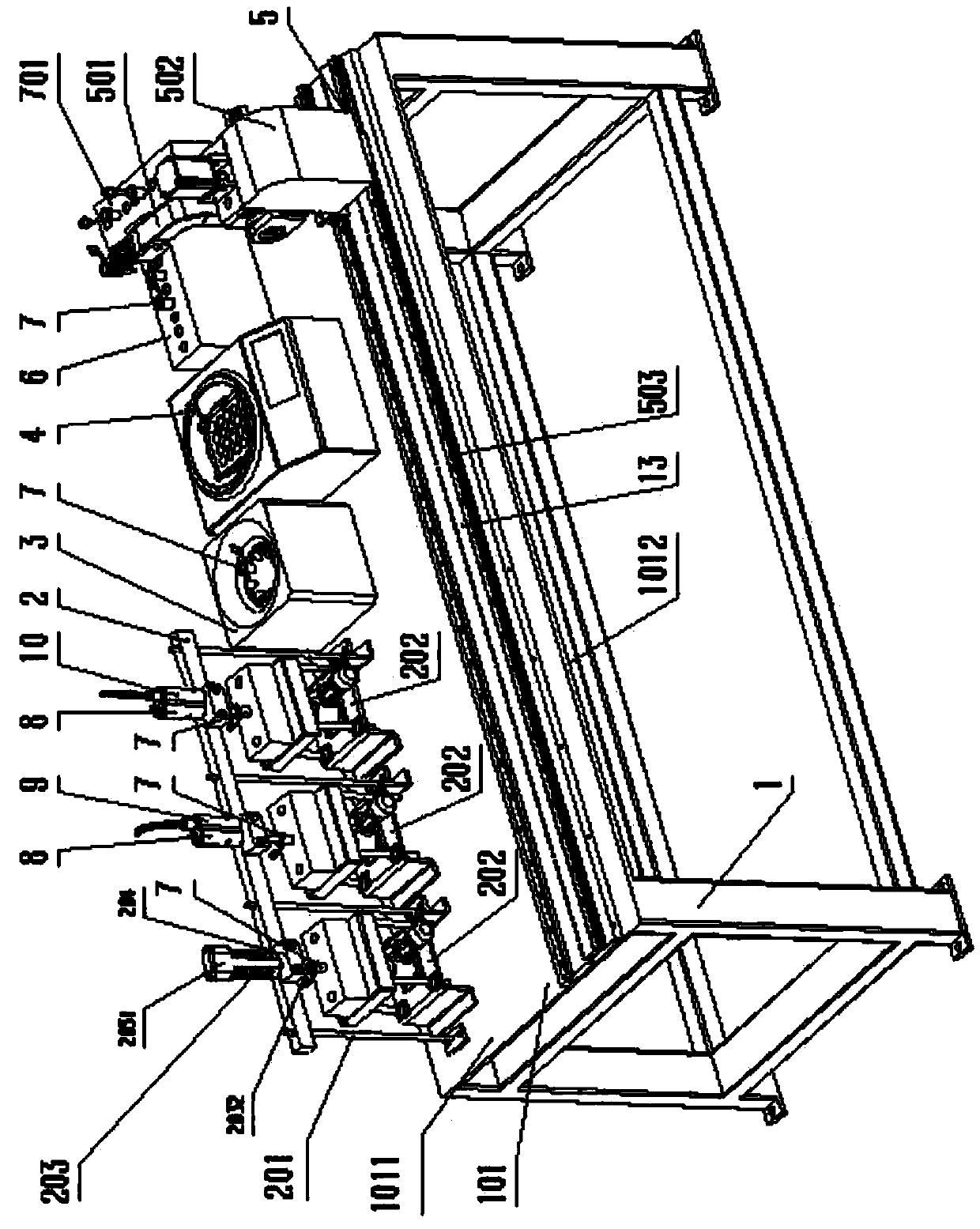

[0035] see Figure 1 to Figure 9 , an automatic sample processing system, which includes a workbench 1, a sample pretreatment device 2, a sample centrifugation device 3, a sample temperature control device 4, a manipulator system 5, and a detection device 6 are arranged on the table 101 of the workbench 1 And test tube rack 701.

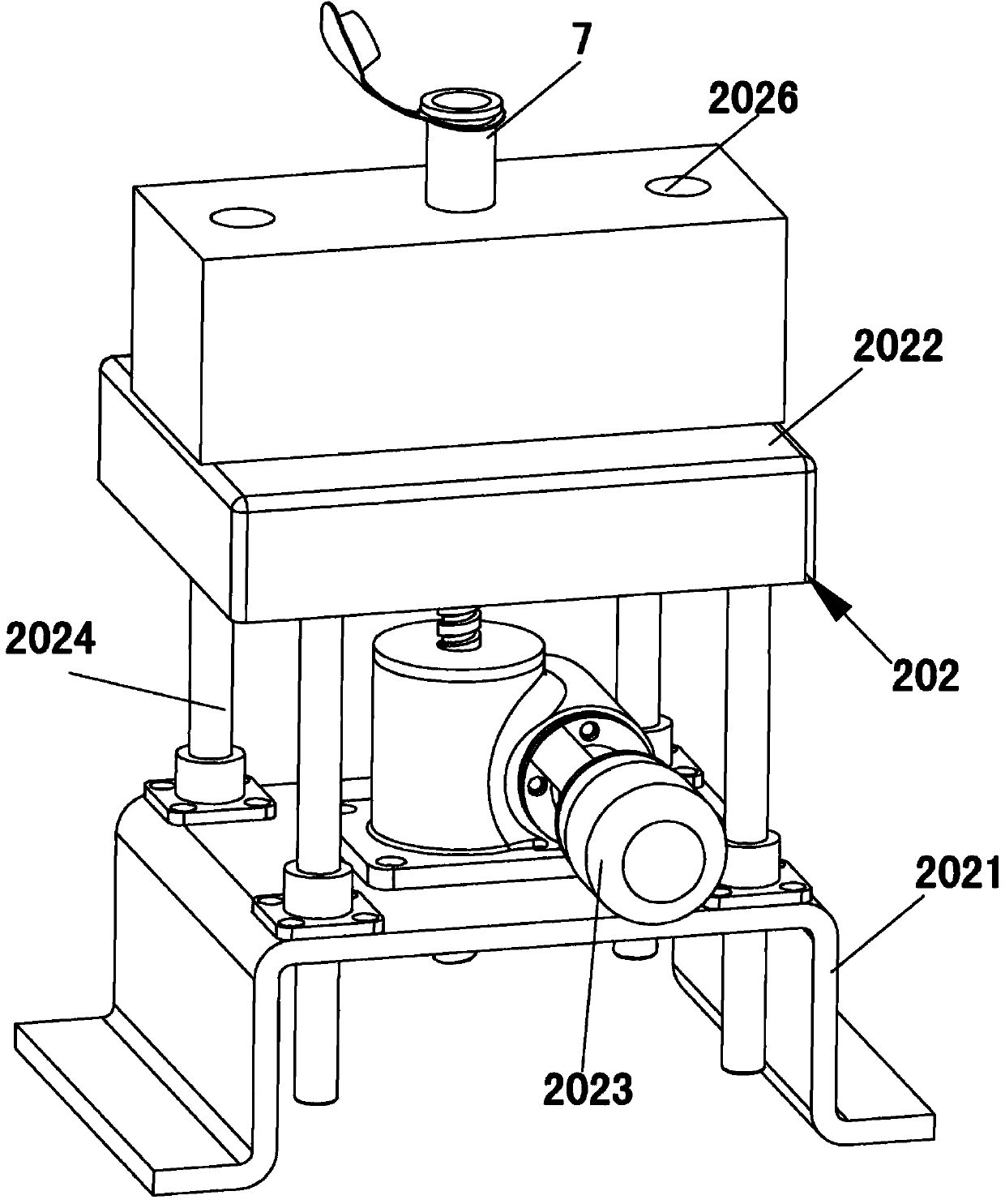

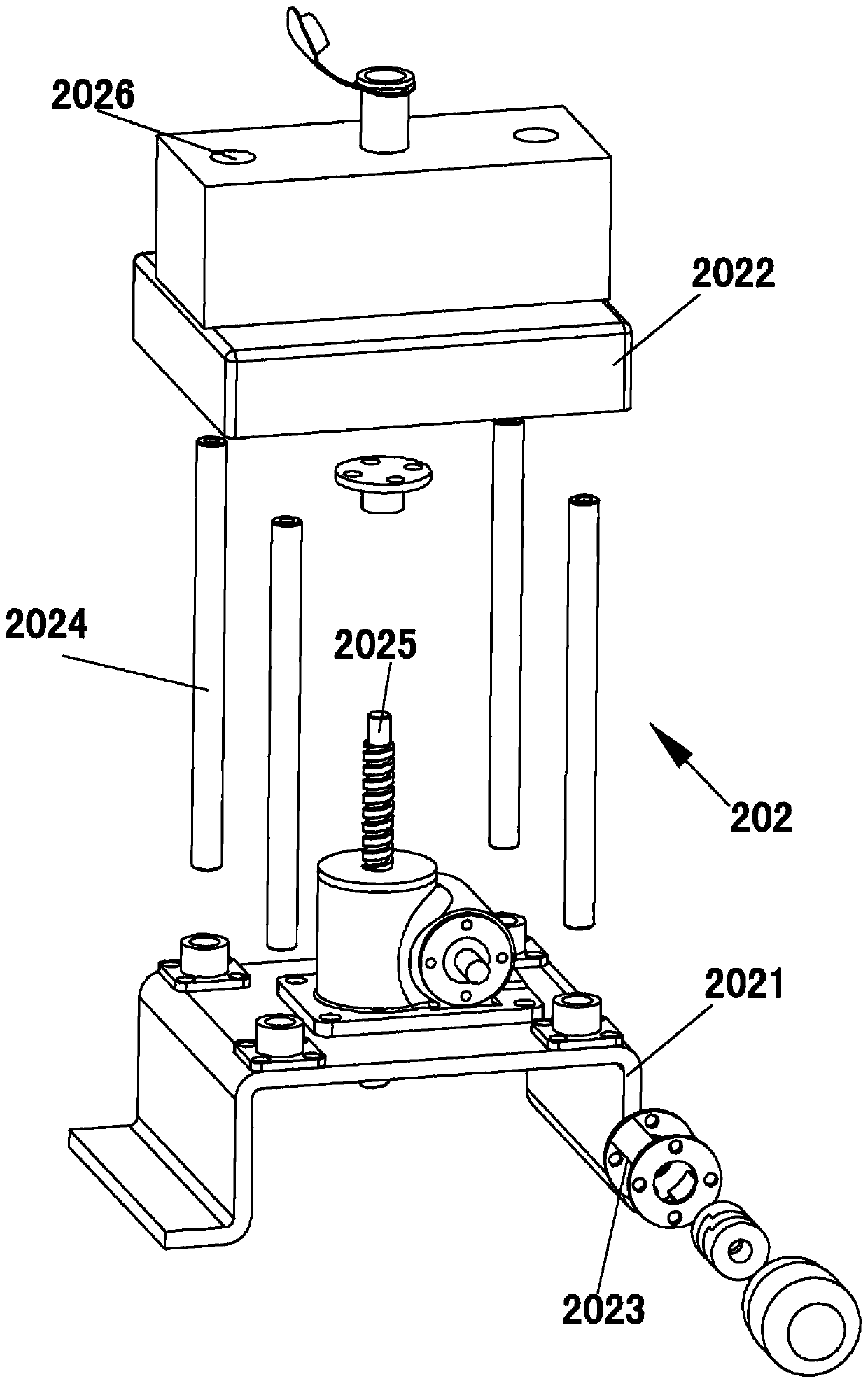

[0036] The sample pretreatment device 2 includes a support 201 and a plurality of test tube holders 202, and a sample crushing device 203 and a plurality of servo burettes 8 for crushing solid samples are arranged on the support 201; The burette 8 includes one or more vertical reagent addition burettes 9 for adding reagents in the test tube 7 and a liquid-taking burette 10 for obtaining the liquid in the test tube 7; Each of the servo-type burettes is fixed on the support 201 through a fixed frame 204; under the sample crushing device 203, a test tube bracket 202 is set; the plurality of servo-type burettes One of the test tube holders 202 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com