a disposable syringe

A syringe and disposable technology, applied in syringes, infusion sets, etc., can solve problems such as hidden medical risks, large errors in taking liquids, and endangering human health, and achieve the goal of improving safety, convenience, and accuracy of liquid taking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

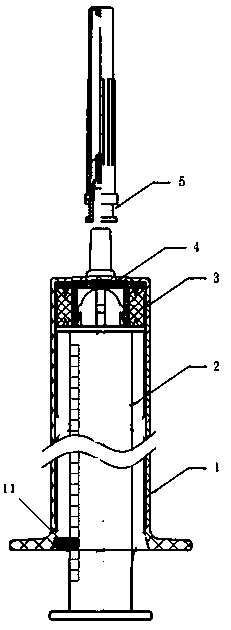

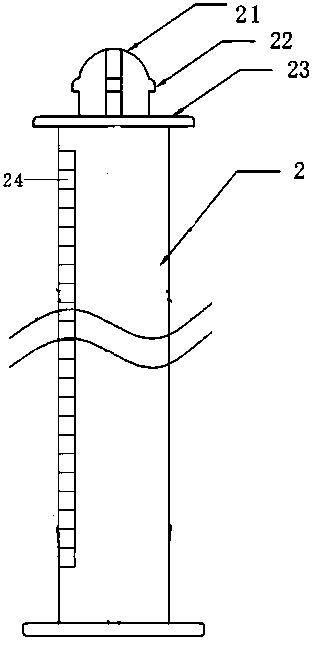

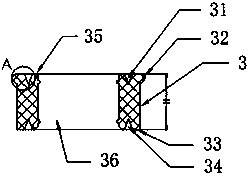

[0022] A disposable syringe consisting of a casing 1, a push rod 2, a rubber plug 3, a rubber plug bushing 4, and an injection needle 5. The push rod 2 is put into the casing 1, wherein the rubber plug 3 in the shape The upper end surface 35 of the plug is processed with an upper annular groove 31 with an upward opening, and the lower end surface 33 of the rubber plug is processed with a lower annular groove 34 with an opening downward. The longitudinal sections of the upper annular groove 31 and the lower annular groove 34 are both V-shaped. A sealing ring 32 is provided on the outer periphery of the upper end surface 35 of the rubber plug 3; an anti-slip convex strip 43 located on the inner ring is provided at the central end surface 47 of the bottom surface 41 of the rubber plug bushing 4, and the rubber plug bushing The outer end surface 46 of the lower part of the bush bottom surface 41 of 4 is provided with an embedding protrusion 42 located on the outer ring, and the hei...

Embodiment 2

[0024] A disposable syringe, wherein the material used for the jacket 1 and its preparation method are as follows: heat 26 parts of medical grade polypropylene, 14 parts of polylactic acid, and 33 parts of polycarbon dioxide resin to 100°C, stir and mix for 20 minutes, and add 1 part of The mixture of stearylamide and erucic acid with a mass ratio of 1:1 was heated to 170°C and continued to mix for 45 minutes, then cooled to 75°C at a rate of 3°C / min, then transferred to a screw machine for extrusion and granulation. Add 100 parts of modified polypropylene and 2 parts of a mixture of acetyl triethyl citrate and di-n-butyl sebacate with a mass ratio of 1:2.5 into the mixer, and heat to 95°C. Stir and mix for 8 minutes, add 3 parts of a mixture of sodium stearate, epoxidized soybean oil and antioxidant 1010 with a mass ratio of 1.7:1:0.6, continue mixing for 20 minutes, transfer to a screw machine for extrusion granulation, and then injection molding ; The material used for rubb...

Embodiment 3

[0026] A disposable syringe, wherein, the material used for the material of jacket 1 and its preparation method are as follows: after heating 26 parts of medical grade polypropylene, 13 parts of polylactic acid, and 30 parts of polycarbonic acid resin to 95°C, stirring and mixing for 20 minutes, adding 2 parts of The mixture of stearamide and erucic acid with a mass ratio of 1:1 is heated up to 175°C and mixed for 45 minutes, then lowered to 70°C at a rate of 3°C / min, and then transferred to a screw machine for extrusion and granulation. Modified polypropylene is ready for use, add 100 parts of modified polypropylene and 3 parts of a mixture of acetyl triethyl citrate and di-n-butyl sebacate with a mass ratio of 1:2.5 into the mixer, and heat to 90°C , stirred and mixed for 5 minutes, added 2 parts of a mixture of sodium stearate, epoxy soybean oil and antioxidant 1010 with a mass ratio of 1.7:1:0.6, continued to mix for 20 minutes, transferred to a screw machine for extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com