Universal conversion switch with magnetic quenching function

A technology of magnetic blowout arc extinguishing and transfer switch, which is applied in the field of switching electrical devices and universal transfer switches, which can solve the problems of shortened service life, different degrees of electric corrosion, and reduced reliability, and achieve reliable operation, small contact resistance, and high reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] specific implementation plan

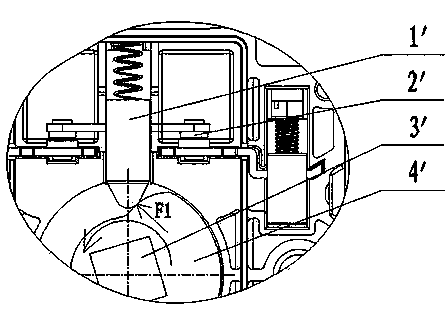

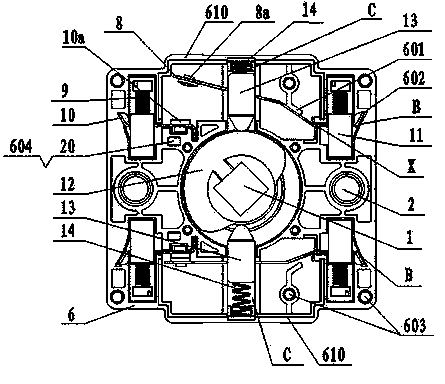

[0049] Such as Figure 2 to Figure 5 As shown, the first specific embodiment of the present invention is a universal transfer switch with a magnetic blowout function, which includes a square shaft 1, a pull rod 2, a front cover 3, a rear cover 7 and multi-layer contacts The box assembly 5 is provided with a baffle plate 4 at both ends of the multi-layer contact box assembly 5 respectively. Tensioned into one, forming a universal transfer switch.

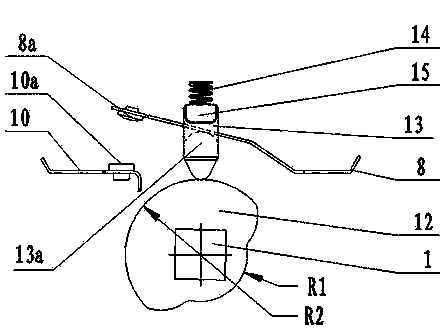

[0050] The contact box assembly 5 includes a contact box 6 and a cam 12 arranged in the cavity of the contact box 6, a moving contact piece 8, a static contact piece 10, a wiring device 11, a moving contact seat 13, a return spring 14 and a return spring seat 15. The square shaft 1 penetrates into the square hole in the middle of the cam 12. The cam 12 adopts a disc-shaped cam with a radius difference, and the radius difference between the major diameter R2 of the cam and the minor diameter R1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com