Camera for high-definition CMOS endoscope

A camera and endoscope technology, applied in the field of endoscope, can solve the problems of difficult assembly, short transmission distance, low resolution, etc., and achieve the effect of solving the problem of reflection, increasing the transmission distance, and improving the resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

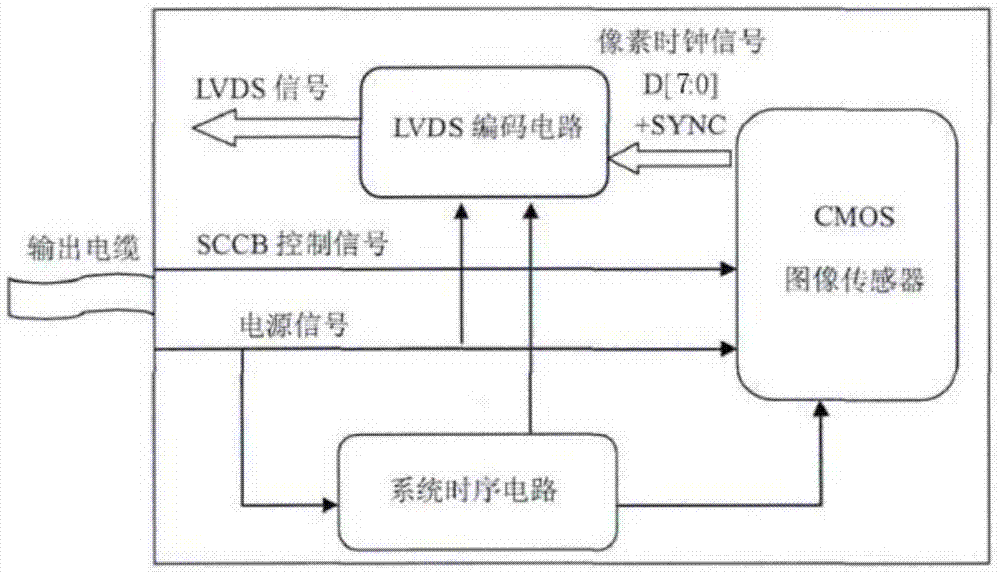

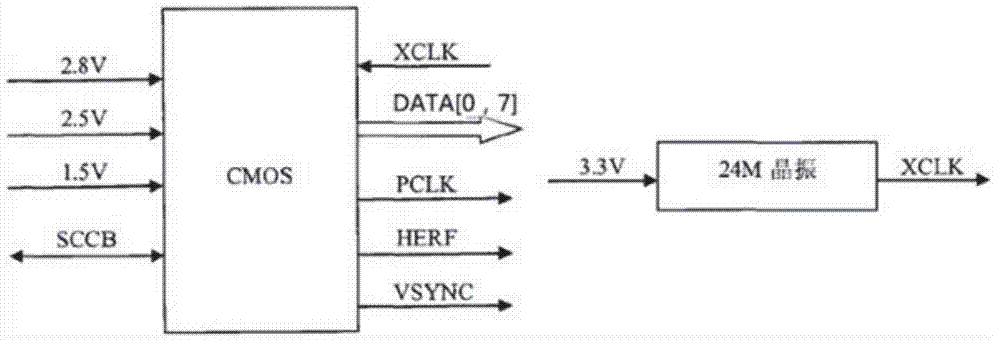

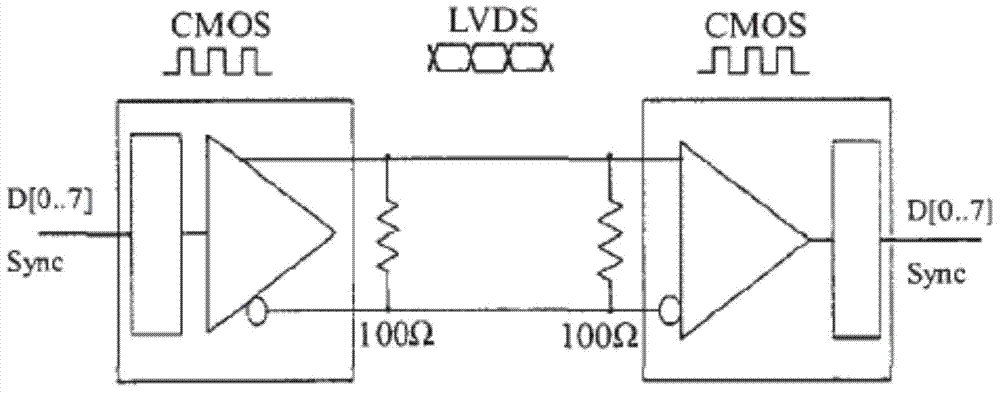

[0018] figure 1 Shown is the camera head of the high-definition CMOS endoscope provided by the present invention, the camera head includes an image sensor, a system timing circuit, an LVDS encoding circuit, a power supply and an SCCB control signal, and the output end of the system timing circuit is connected to the input of the image sensor terminal, the output terminal of the image sensor is connected to the input terminal of the LVDS encoding circuit, the output terminal of the LVDS encoding circuit outputs a signal, the SCCB control signal is input to the image sensor, and the power supply unit is electrically connected to the Image sensor, system timing circuit and LVDS encoding circuit. A CMOS sensor with a resolution of up to 720P is used, and the frame rate can reach 30fps, which reduces the size of the camera and increases the pixels. It uses LVDS coding technology to output video signals for coding, which improves the resolution, increases the transmission distance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com