Rare earth complex rubber aging inhibitor as well as preparation method and applications thereof

A technology of rubber antioxidant and rare earth complex, applied in the field of rubber auxiliaries, can solve problems such as poor aging resistance, and achieve the effects of stable properties, simple and feasible reaction, and not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

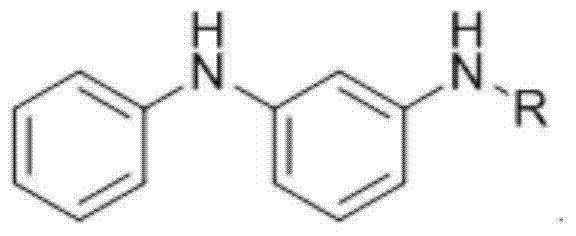

Method used

Image

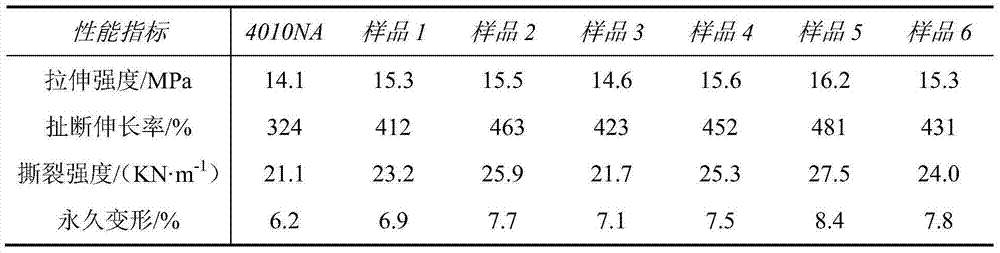

Examples

Embodiment 1

[0018] Add 1 mol of samarium oxide into 500mL concentrated hydrochloric acid, stir and dissolve while adding, the reaction is exothermic, and a transparent light yellow rare earth chloride solution is obtained, and the excess concentrated hydrochloric acid and water are removed by heating to obtain a light yellow solid, which is dried at a constant temperature of 60 degrees for 12 hours. The product samarium chloride is obtained. Dissolve 1mol of N-isopropyl-N'-phenyl-p-phenylenediamine in 200mL of ethanol, 1mol of samarium chloride in 200mL of ethanol, then add the ethanol solution of samarium chloride dropwise to N-isopropyl-N' -In the ethanol solution of phenyl-p-phenylenediamine, put it into a 30-degree water bath to heat and react for 0.5 hours. After the reaction is completed, remove excess ethanol by rotary evaporation to obtain a thick liquid, which is put into a vacuum drying oven, Dry at 30 degrees to constant weight, then take it out, grind and sieve to obtain the r...

Embodiment 2

[0020] Add 1 mol of samarium oxide into 500mL concentrated hydrochloric acid, stir and dissolve while adding, the reaction is exothermic, and a transparent light yellow rare earth chloride solution is obtained, and the excess concentrated hydrochloric acid and water are removed by heating to obtain a light yellow solid, which is dried at a constant temperature of 60 degrees for 12 hours. The product samarium chloride is obtained. Dissolve 3 mol of N-isopropyl-N'-phenyl-p-phenylenediamine in 200 mL of ethanol, 1 moL of samarium chloride in 200 mL of ethanol, and then add the ethanol solution of samarium chloride dropwise to N-isopropyl-N'- In the ethanol solution of phenyl-p-phenylenediamine, put it into a 30-degree water bath to heat and react for 1 hour. After the reaction is completed, remove excess ethanol by rotary evaporation to obtain a thick liquid, which is put into a vacuum drying oven for 30 Dry to constant weight, then take out, grind and sieve to obtain the rare ea...

Embodiment 3

[0022] Add 1 mol of samarium oxide into 500mL concentrated hydrochloric acid, stir and dissolve while adding, the reaction is exothermic, and a transparent light yellow rare earth chloride solution is obtained, and the excess concentrated hydrochloric acid and water are removed by heating to obtain a light yellow solid, which is dried at a constant temperature of 60 degrees for 12 hours. The product samarium chloride is obtained. Dissolve 5 mol of N-isopropyl-N'-phenyl-p-phenylenediamine in 200 mL of ethanol, 1 moL of samarium chloride in 200 mL of ethanol, and then add the ethanol solution of samarium chloride dropwise to N-isopropyl-N'- In the ethanol solution of phenyl-p-phenylenediamine, put it into a 30-degree water bath to heat and react for 1 hour. After the reaction is completed, remove excess ethanol by rotary evaporation to obtain a thick liquid, which is put into a vacuum drying oven for 30 Dry to constant weight, then take out, grind and sieve to obtain the rare ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com