Tire rubber and its preparation method

A technology of rubber and tires, applied in the direction of special tires, tire parts, rolling resistance optimization, etc., can solve the problems of tire product wear, use, high maintenance costs, short service life, etc., to increase tensile strength and increase service life , Improve the effect of ozone resistance and heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

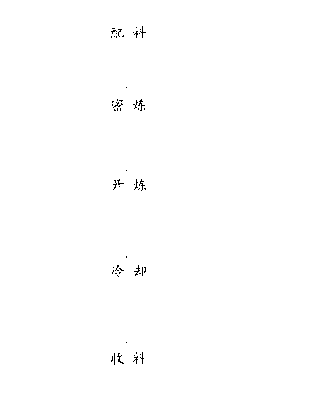

Method used

Image

Examples

Embodiment 1

[0027] A kind of rubber for tires, the rubber includes the following components in weight percentage: 6% of natural rubber, 11.25% of butadiene rubber, 12% of styrene-butadiene rubber, 13% of carbon black N339, 12% of carbon black N220, and 0.5% of tackifying resin , Antiaging agent RD 0.5%, Antiaging agent BLE 0.5%, Antiaging agent 7F 1%, Microcrystalline wax 0.5%, Vulcanizing agent accelerator 2%. The remaining additives are 40.75%. The additives are various components commonly used in the rubber field, mainly zinc oxide, stearic acid, processing aids, reclaimed rubber powder, and a mixture of one or more of aromatic oils. It is an additive mainly used to improve the processing performance and use performance of rubber. It can increase the plasticity of the rubber, reduce the viscosity of the rubber and the temperature during mixing, improve the dispersion and mixing, and increase the tensile strength of the vulcanized rubber. elongation and abrasion resistance.

[0028] Na...

Embodiment 2

[0037] All the other are identical with embodiment 1, difference is that this rubber comprises the component of following percentage by weight: natural rubber 10%, butadiene rubber 18.85%, styrene-butadiene rubber 20%, carbon black N339 17%, carbon black N220 17% 1.5% tackifying resin, 1.5% antioxidant RD, 1.5% antioxidant BLE, 3% antioxidant 7F, 1.2% microcrystalline wax, 4% vulcanizing agent accelerator, and 4.45% other additives.

Embodiment 3

[0039] All the other are identical with embodiment 1, difference is that this rubber comprises the component of following percentage by weight: natural rubber 6.5%, butadiene rubber 12.2%, styrene-butadiene rubber 13%, carbon black N339 13.5%, carbon black N220 13% , 0.8% tackifying resin, 0.7% antioxidant RD, 0.7% antioxidant BLE, 1.2% antioxidant 7F, 0.6% microcrystalline wax, 2.3% vulcanizing agent accelerator, and 35.5% other additives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com