Powder coating for fire-proof electronic element and preparation method thereof

A technology for powder coatings and electronic components, applied in powder coatings, fire-resistant coatings, epoxy resin coatings, etc., can solve the problems of high fire-proof requirements for electronic components and powder coatings that cannot meet their requirements, and achieve good fire-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

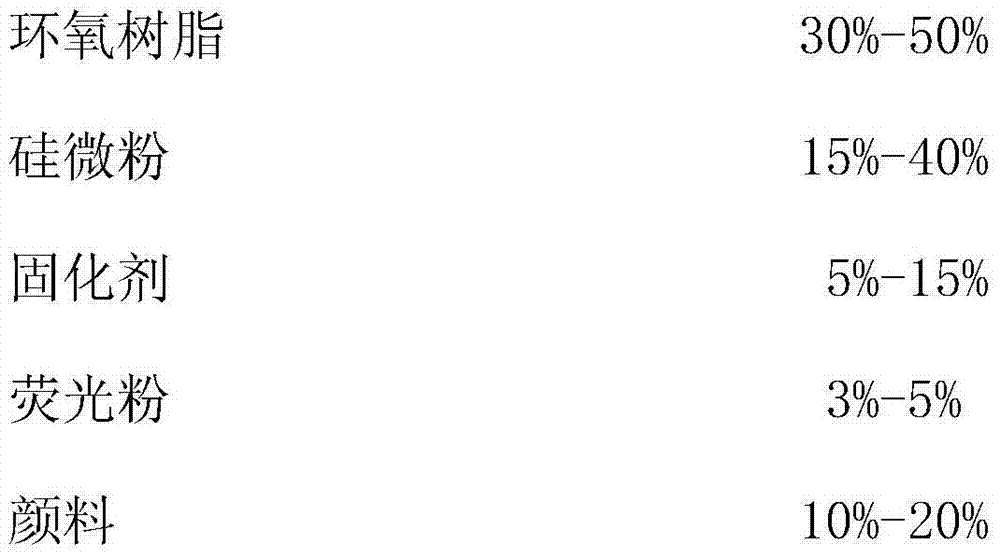

[0033] The invention provides a kind of fireproof electronic component powder coating, which is composed of the following components by weight percentage:

[0034]

[0035] The curing agent is an organic acid or acid anhydride curing agent.

[0036] The epoxy equivalent of the epoxy resin is 5000-10000g / eq.

[0037] The expanded vermiculite powder is obtained by grinding raw vermiculite flakes after high-temperature roasting.

[0038] A preparation method for a fireproof electronic component powder coating, comprising the following steps:

[0039] Step 1: After turning on the mixer, add epoxy resin-curing agent-expanded vermiculite powder-organosilicon powder-pigment-organosilicon powder-phosphor powder into the mixer and stir evenly;

[0040] Step 2: Put the uniformly stirred raw materials into an extruder to heat and extrude. The heating temperature is 120° C., and the extruded semi-finished product is in the shape of a sheet.

[0041] Step 3: put the flaky semi-finish...

Embodiment 2

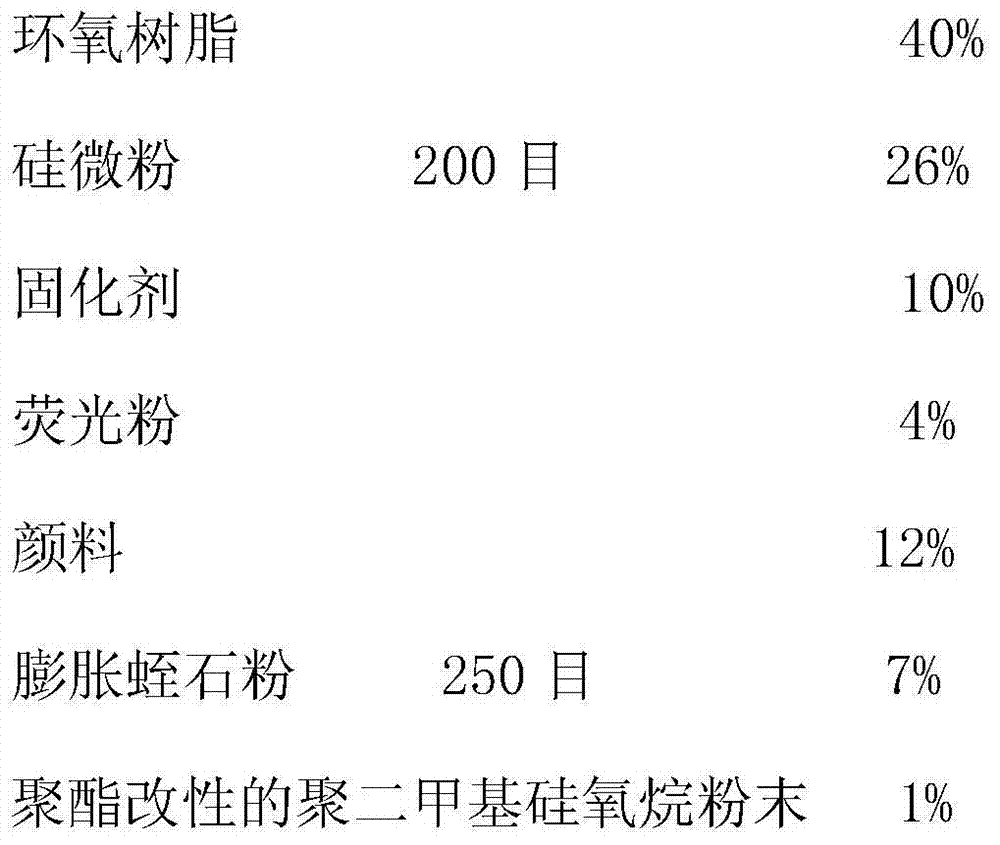

[0043] The invention provides a kind of fireproof electronic component powder coating, which is composed of the following components by weight percentage:

[0044]

[0045] The curing agent is an organic acid or acid anhydride curing agent.

[0046] The epoxy equivalent of the epoxy resin is 5000-10000g / eq.

[0047] The expanded vermiculite powder is obtained by grinding raw vermiculite flakes after high-temperature roasting.

[0048] A preparation method for a fireproof electronic component powder coating, comprising the following steps:

[0049] Step 1: After turning on the mixer, add epoxy resin-curing agent-expanded vermiculite powder-organosilicon powder-pigment-organosilicon powder-phosphor powder into the mixer and stir evenly;

[0050] Step 2: Put the uniformly stirred raw materials into an extruder to heat and extrude. The heating temperature is 80° C., and the extruded semi-finished product is in the shape of a sheet.

[0051] Step 3: put the flaky semi-finishe...

Embodiment 3

[0053] The invention provides a kind of fireproof electronic component powder coating, which is composed of the following components by weight percentage:

[0054]

[0055] The curing agent is an organic acid or acid anhydride curing agent.

[0056] The epoxy equivalent of the epoxy resin is 5000-10000g / eq.

[0057] The expanded vermiculite powder is obtained by grinding raw vermiculite flakes after high-temperature roasting.

[0058] A preparation method for a fireproof electronic component powder coating, comprising the following steps:

[0059] Step 1: After turning on the mixer, add epoxy resin-curing agent-expanded vermiculite powder-organosilicon powder-pigment-organosilicon powder-phosphor powder into the mixer and stir evenly;

[0060]Step 2: Put the uniformly stirred raw materials into an extruder to heat and extrude. The heating temperature is 140° C., and the extruded semi-finished product is in the shape of a sheet.

[0061] Step 3: put the flaky semi-finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap