System and method for detecting explosion-proof performance of separation explosion-proof material

A technology for blocking explosion-proof materials and measuring systems, which is applied in the direction of material explosion, can solve the problems of increasing processing and use costs, and cannot reflect, and achieve the effects of avoiding human interference, ensuring consistency, and ensuring personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

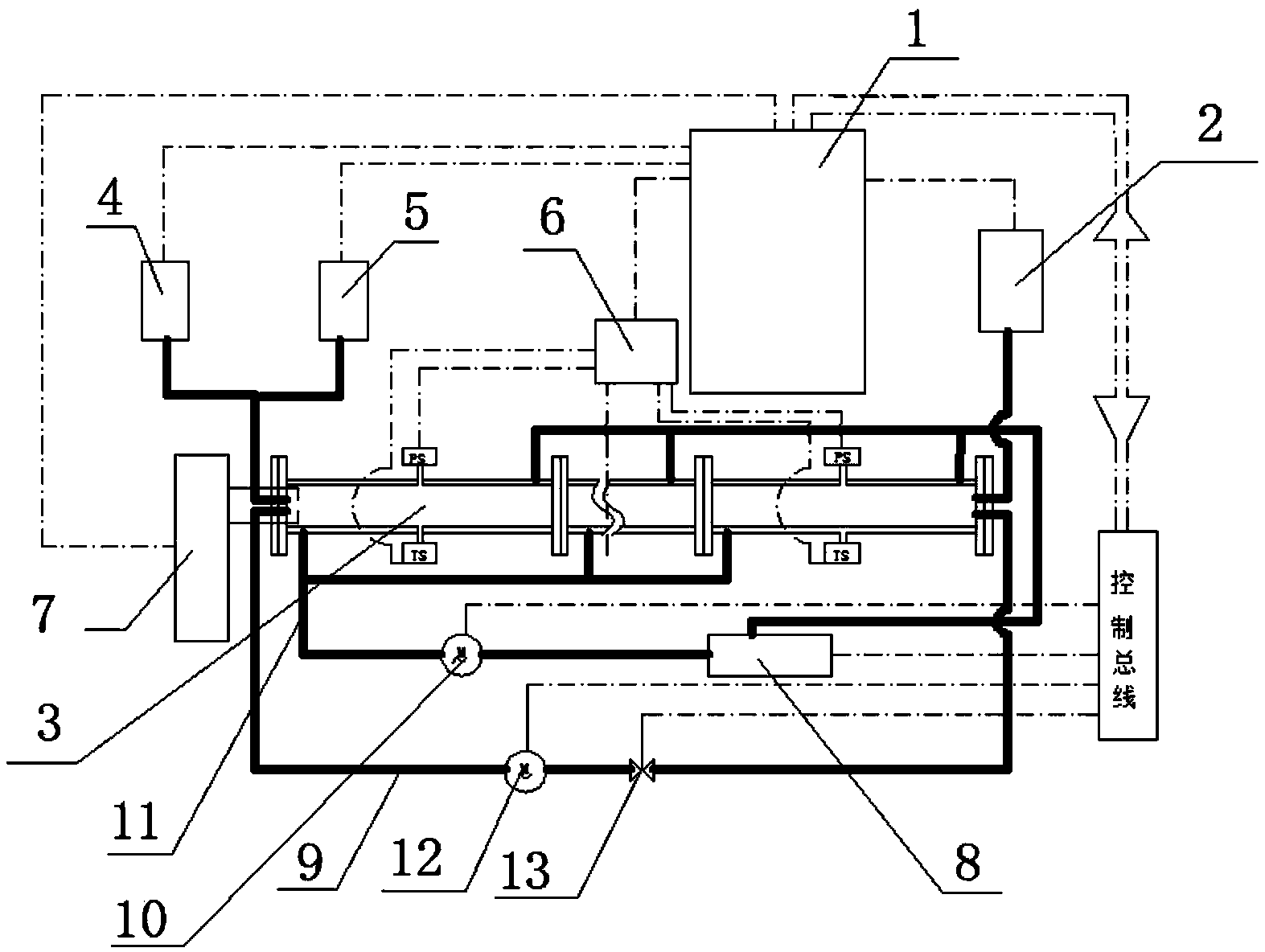

[0053] Such as figure 2 Shown, a kind of barrier explosion-proof material explosion-proof performance measuring system, comprises computer, explosion chamber 3, gas circulation pipeline 9, main control system 1 and the first vacuumizing device 2 connected with it by wire, liquid fuel vapor supply device 4, Dry air supply device 5, information collection device 6 and ignition device 7; The explosion chamber 3 is a hollow tubular structure with two ends closed; The first vacuum device 2, the liquid fuel vapor supply device 4 and the drying The air supply device 5 is all communicated with the hollow part of the explosion chamber 3; the gas circulation pipeline 9 communicates with the two ends of the explosion chamber 3, and the gas circulation pipeline 9 is equipped with a gas circulation pump 12 and a gas circulation pipeline. The circulation control valve 13, the gas circulation pump 12 and the gas circulation control valve 13 are all connected with the main control system 1; ...

Embodiment 2

[0058] A method for measuring the explosion-proof performance of the barrier explosion-proof material using the measurement system for the explosion-proof performance of the barrier explosion-proof material in Example 1, comprising the following steps:

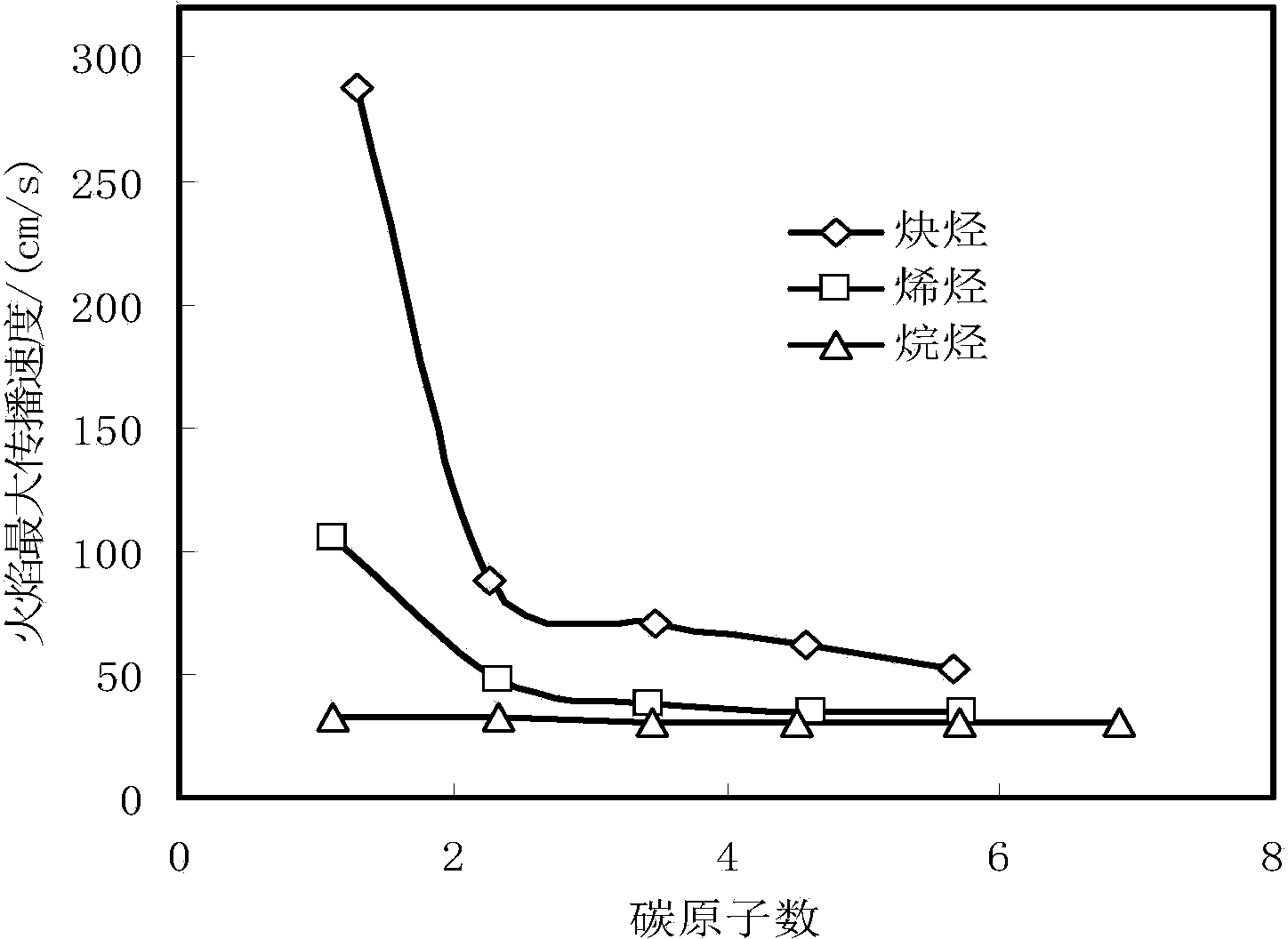

[0059] A. Select liquid fuel and prepare liquid fuel vapor; determine the length of the explosion chamber;

[0060] B. Use the first vacuum device 2 to evacuate the explosion chamber 3; transport the liquid fuel vapor to the explosion chamber 3 through the liquid fuel vapor supply device 4, and then pass through the dry air The supply device 5 transports dry air to the explosion chamber 3 and balances it to a standard atmospheric pressure, turns on the gas circulation pump 12 and opens the gas circulation control valve 13 to transfer the liquid fuel vapor and the dry air through the gas circulation pipeline 9. The air is mixed to obtain a mixed gas, and the mixed gas is obtained by mixing; the mixed gas is detonated by the ign...

Embodiment 3

[0063] A method for measuring the explosion-proof performance of the barrier explosion-proof material using the measurement system for the explosion-proof performance of the barrier explosion-proof material in Example 1, comprising the following steps:

[0064] A. Select liquid fuel: For the measurement of the explosion-proof performance of the barrier explosion-proof material suitable for gasoline vapor, the gasoline model compound is selected as the gasoline model compound. The gasoline model compound is composed of n-heptane and isooctane with a volume ratio of 1:9; For the determination of the explosion-proof performance of the barrier explosion-proof material for diesel vapor, a diesel model compound is used, and the diesel model compound is C 9 -C 18 At least one of paraffins and naphthenes;

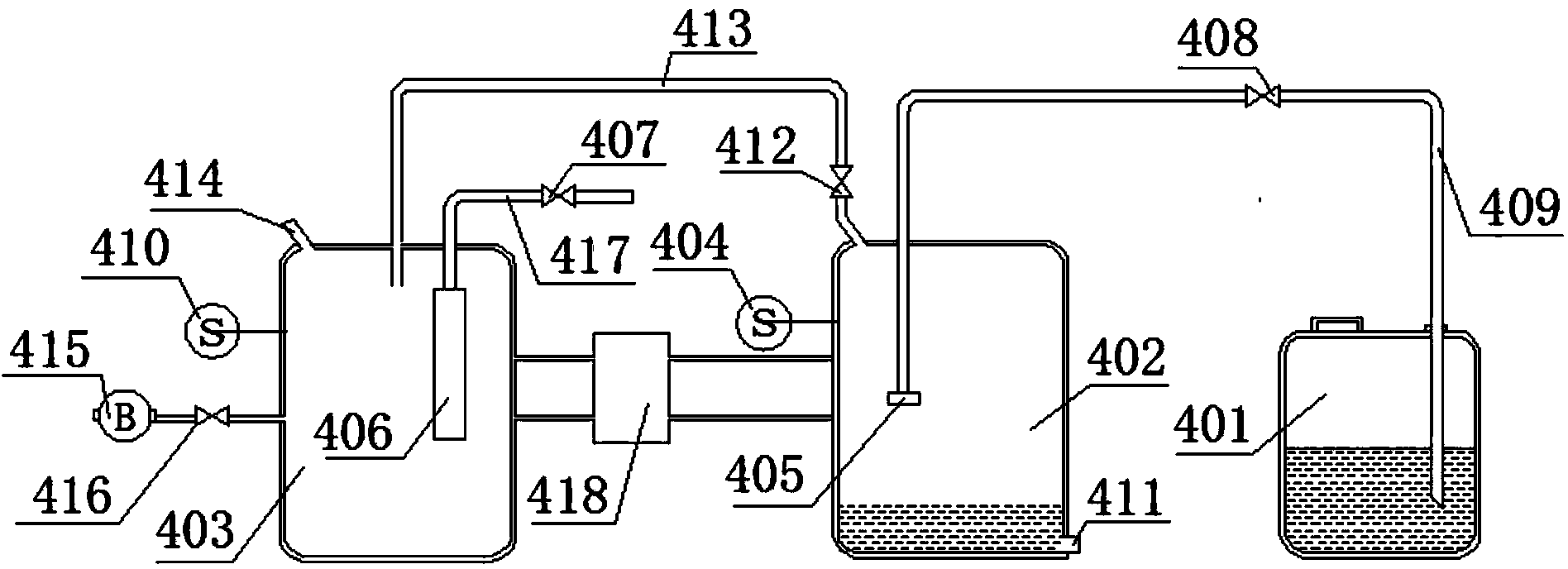

[0065] Prepare liquid fuel vapor: turn on the second vacuum device 415 to evacuate the vapor generating tank 402 and the vapor storage tank 403 to a vacuum degree of 0.75-1.5Kpa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com