A general printing method for substation devices based on middleware

A general-purpose printing and substation technology, applied in the direction of digital output to printing unit, electrical digital data processing, data processing input/output process, etc., can solve the bottleneck of difficult to flexibly adapt to the type of printing interface, low printing speed, and printing performance improvement and other issues to achieve the effect of saving secondary development costs and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

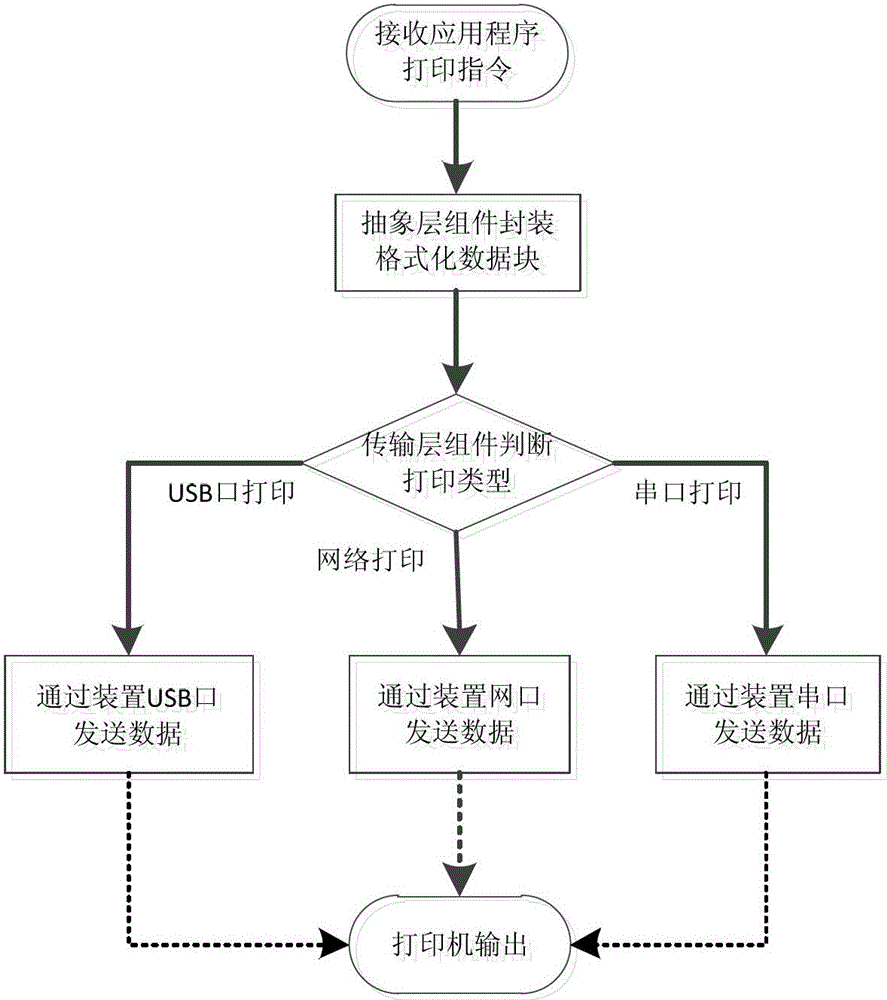

[0014] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

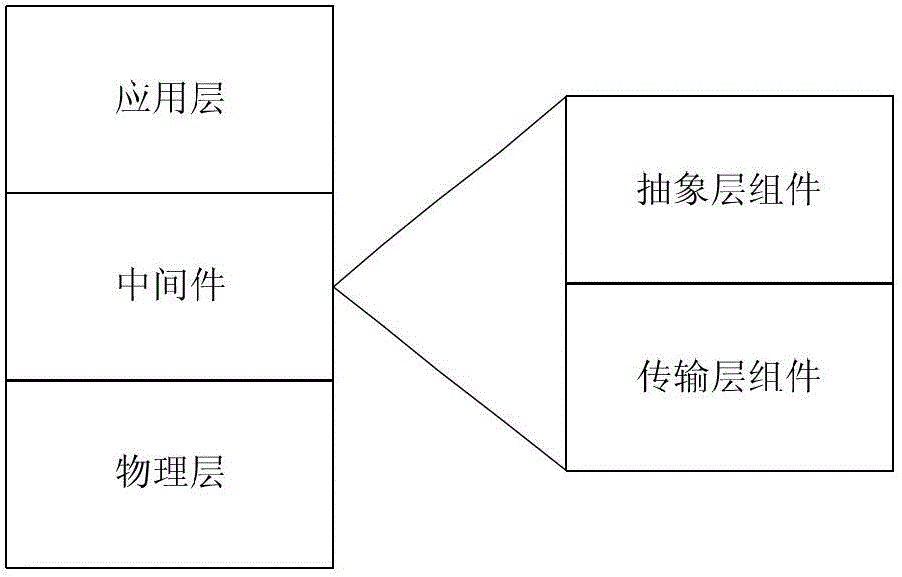

[0015] The present invention provides a middleware-based universal printing method for substation devices. The substation device includes an application layer, middleware, and a physical layer, and the middleware is located between the application layer and the physical layer, reducing the device application layer and physical layer. The coupling between the layers improves the versatility of the printing application of the device, and provides a common implementation interface between different printing applications of the substation device and different types of printers.

[0016] Such as figure 1 As shown, it is a schematic diagram of the implementation architecture of the present invention. The middleware is divided into an abstract layer component and a transport layer component according to functions. These two components communicate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com