Polycrystalline silicon manufacturing method

A production method and technology of polysilicon, applied in the direction of manufacturing tools, semiconductor/solid-state device manufacturing, laser welding equipment, etc., can solve problems such as the inability of the amorphous silicon layer to reach the melting temperature, high excimer laser energy, and unstable crystallization rate of polysilicon , to achieve the effects of reducing the number of launches, reducing costs, and reducing temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will combine Figure 2 to Figure 6 The present application is described in detail, wherein the same reference numerals represent the same or similar devices, substances or steps.

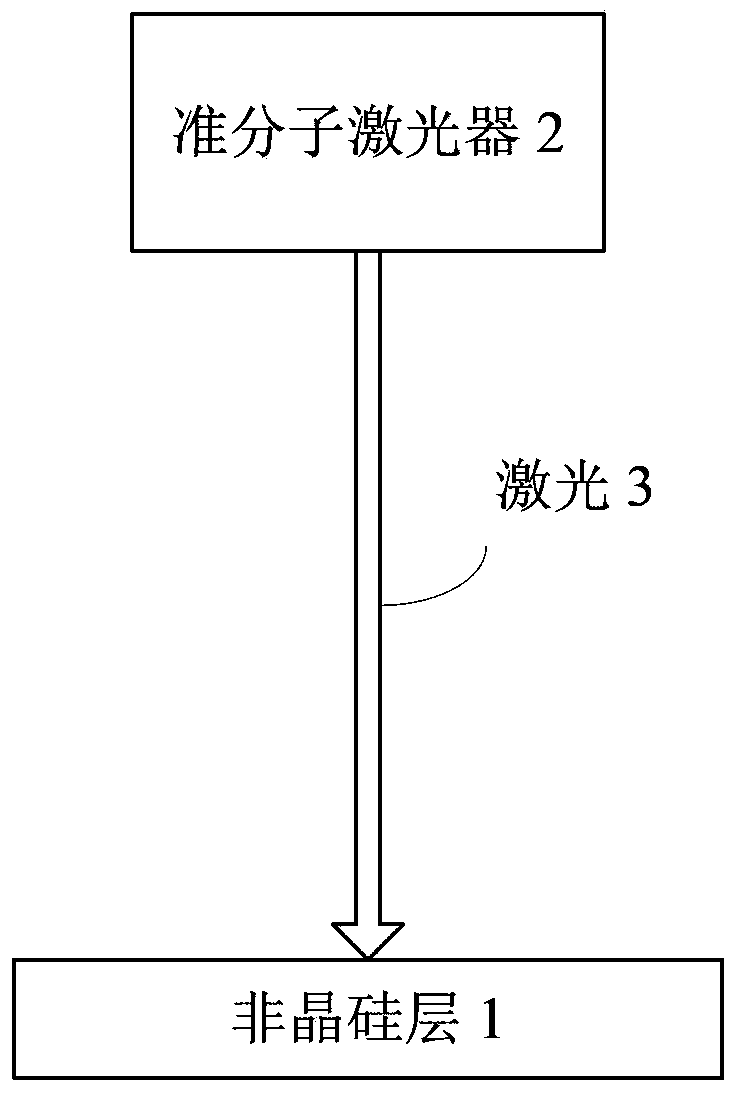

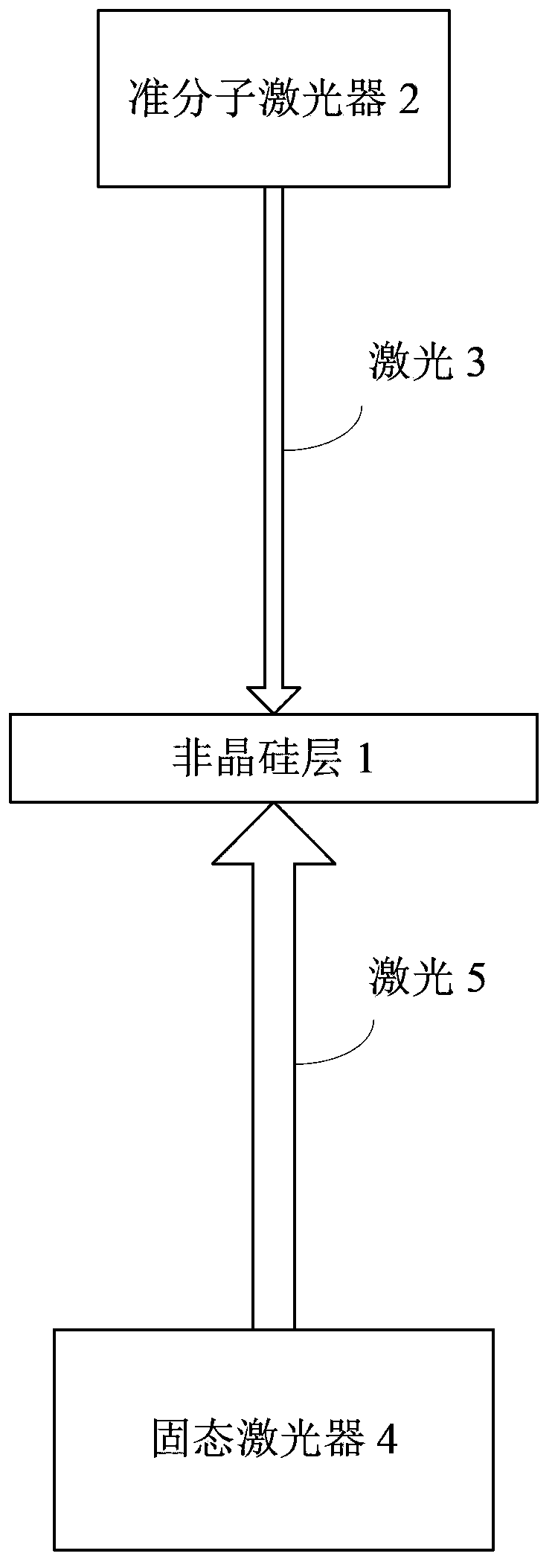

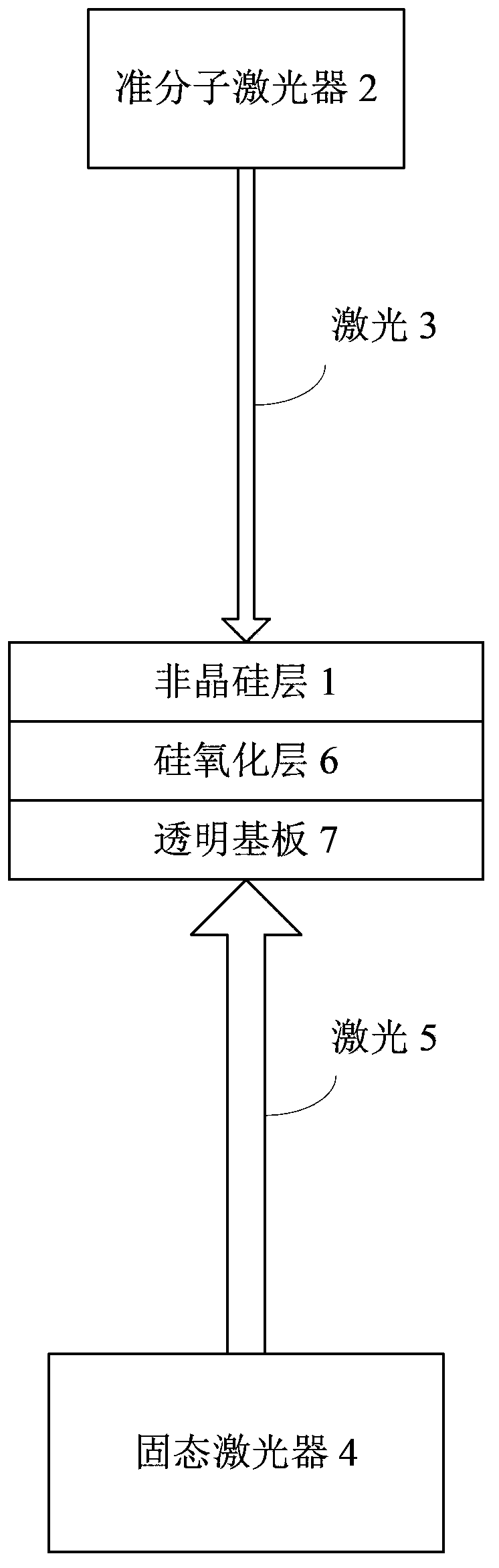

[0026] figure 2 A schematic diagram illustrating a method for fabricating polysilicon using excimer laser annealing according to the first embodiment of the present application is exemplarily shown. Such as figure 2 as shown in the figure 1 The polysilicon manufacturing method that adopts excimer laser annealing in the prior art shown in is different, and the present application except using excimer laser 2 to emit laser light 3 to irradiate the upper surface of amorphous silicon layer 1, also uses solid-state laser 4 to emit The laser 5 is used to irradiate the lower surface of the amorphous silicon layer 1 to preheat or assist the heating of the amorphous silicon layer 1, thereby facilitating the melting of the amorphous silicon layer 1 and crystallization into polysilico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com