Core structure of lithium battery and assembling method of core structure

A lithium battery and core technology, which is applied in the core structure and assembly field of lithium batteries, can solve the problems of burrs on the edge of pole pieces, affecting the performance of lithium batteries, and low qualified rate of finished products, so as to reduce burrs, save production costs, The effect of high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

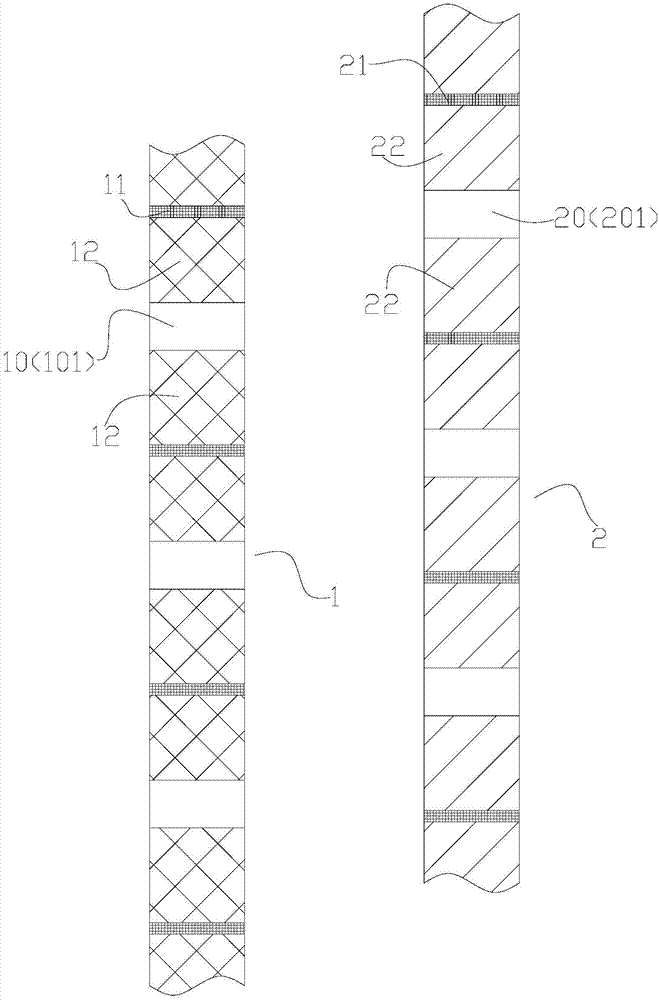

[0051] like Figure 1-5 As shown, the core structure of the lithium battery of the present invention includes a positive electrode sheet 1, a negative electrode sheet 2, a separator 3, an outer positive electrode ear and an outer negative electrode ear, and the positive electrode sheet 1 includes a first substrate 10, a first insulating material layer 11 and the positive polar material layer 12, the first insulating material layer 11 and the positive polar material layer 12 are all coated on one surface of the first substrate 10, and the first substrate 10 also has a reserved positive tab region 101, wherein, The first insulating material layer 11, the positive polarity material layer 12, the reserved positive tab area 101, and the positive polarity material layer 12 are arranged repeatedly in sequence, and the negative electrode sheet 2 includes a second substrate 20, a second insulating material layer 21 and a negative polarity material layer 22. Both the second insulating m...

Embodiment 2

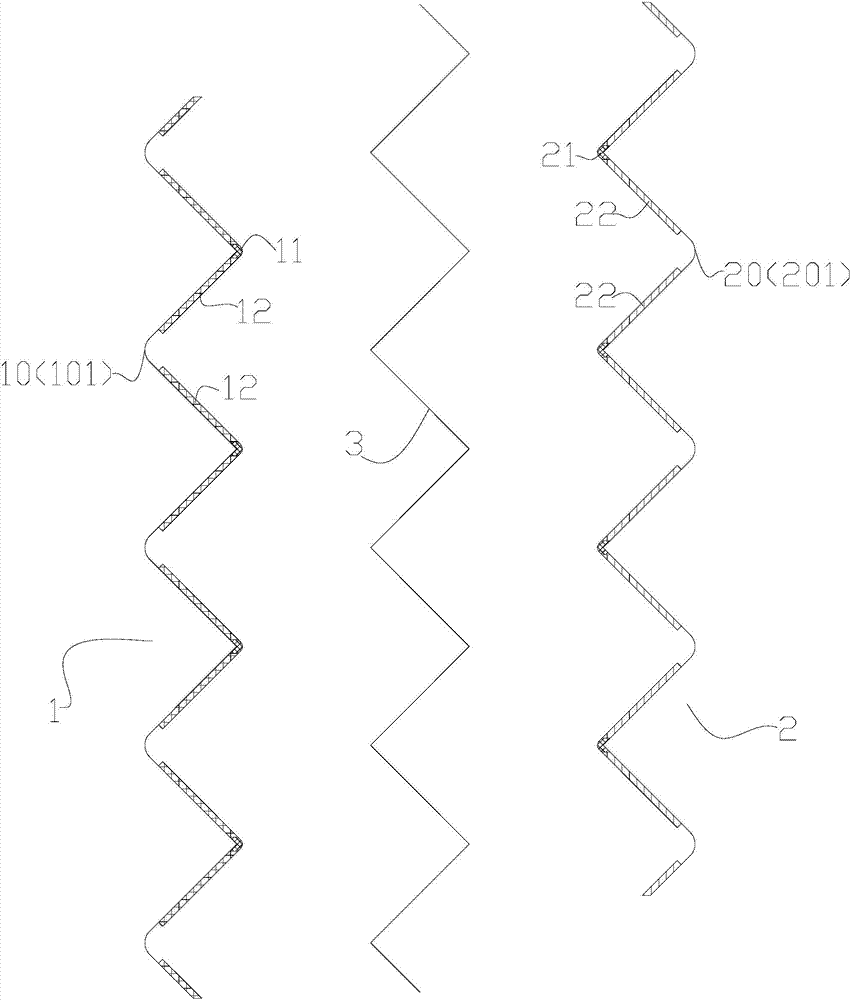

[0055] The only difference between this embodiment and embodiment 1 is: as Figure 6-7 As shown, the width of the first substrate 10 at the reserved positive tab region 101 and the width of the first substrate 10 at the first insulating material layer 11 are respectively smaller than the width of the first substrate 10 at other positions (for example, at The width of the first substrate 10 at the positive polar material layer 12), the width of the second substrate 20 at the reserved negative tab region 201 and the width of the second substrate 20 at the second insulating material layer 21 are respectively smaller than those at other The width of the second substrate 20 at the site (for example, the width of the second substrate 20 at the negative polarity material layer 22).

Embodiment 3

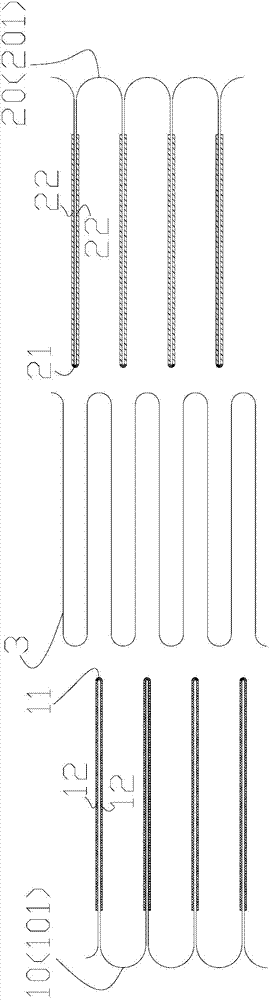

[0057] like Figure 8-17As shown, the core structure of the lithium battery of the present invention includes a positive electrode sheet 4, a negative electrode sheet 5, a separator 6, an outer positive electrode ear and an outer negative electrode ear. The positive electrode sheet 4 includes a first substrate 40 and a plurality of electrodes extending to the first substrate. The positive tab 43 outside the sheet 40 is repeatedly coated with a first insulating material layer 41 and a positive polar material layer 42 on one surface of the first substrate 40, and each positive tab 43 is connected to each positive polar material layer 42 respectively. They are all connected to the outer positive tabs. The negative electrode sheet 5 includes a second substrate 50 and a plurality of negative tabs 53 extending outside the second substrate 50. One surface of the second substrate 50 is repeatedly coated with a second insulating layer in sequence. The material layer 51 and the negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com