Oil and fat composition suitable for non-tempering hard butter

A technology for oil composition and quality, which can be applied in the directions of edible oil/fat, oil/fat refining, oil/fat separation, etc., and can solve the problems of affecting the mold release properties of chocolate and low chocolate productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

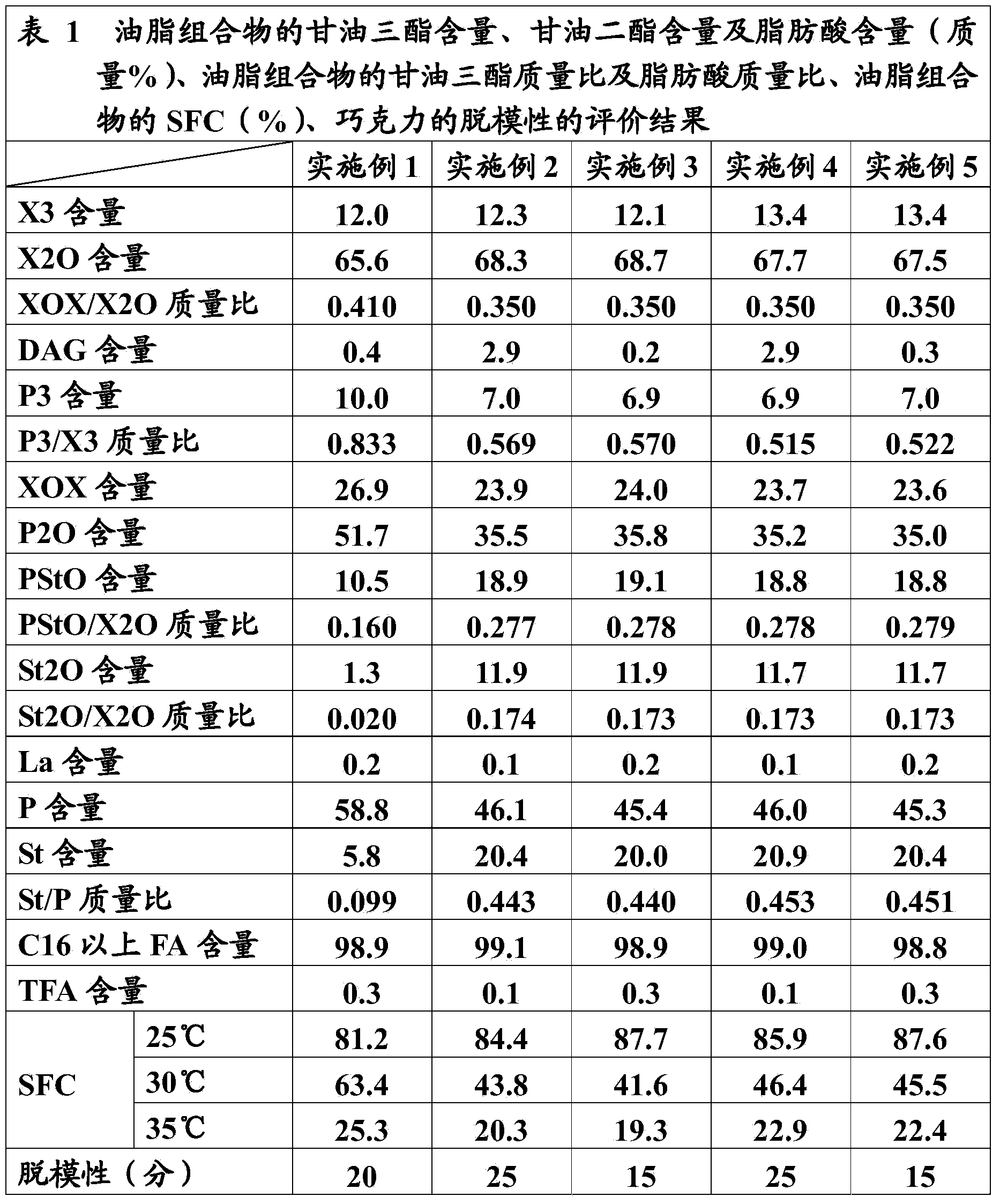

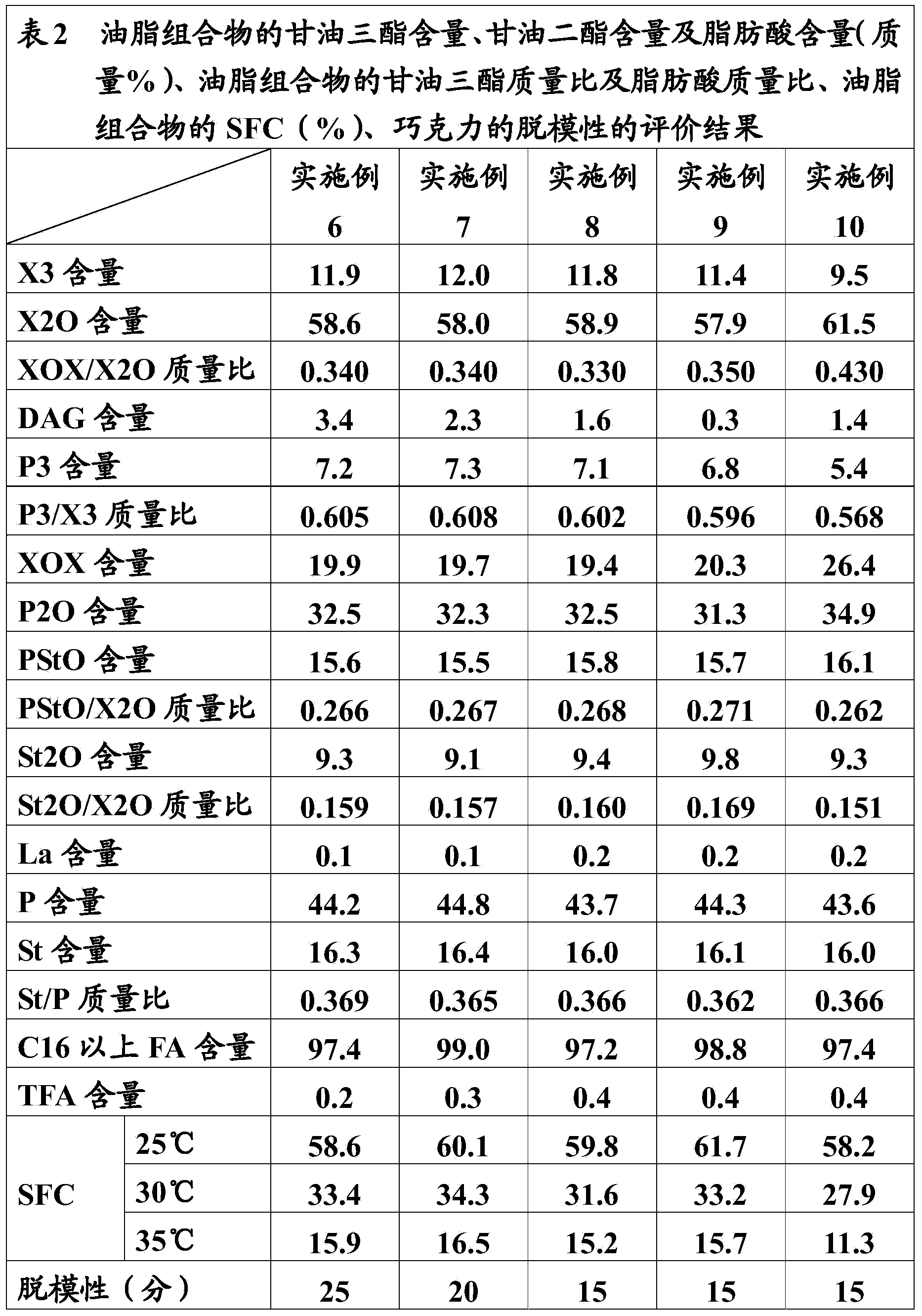

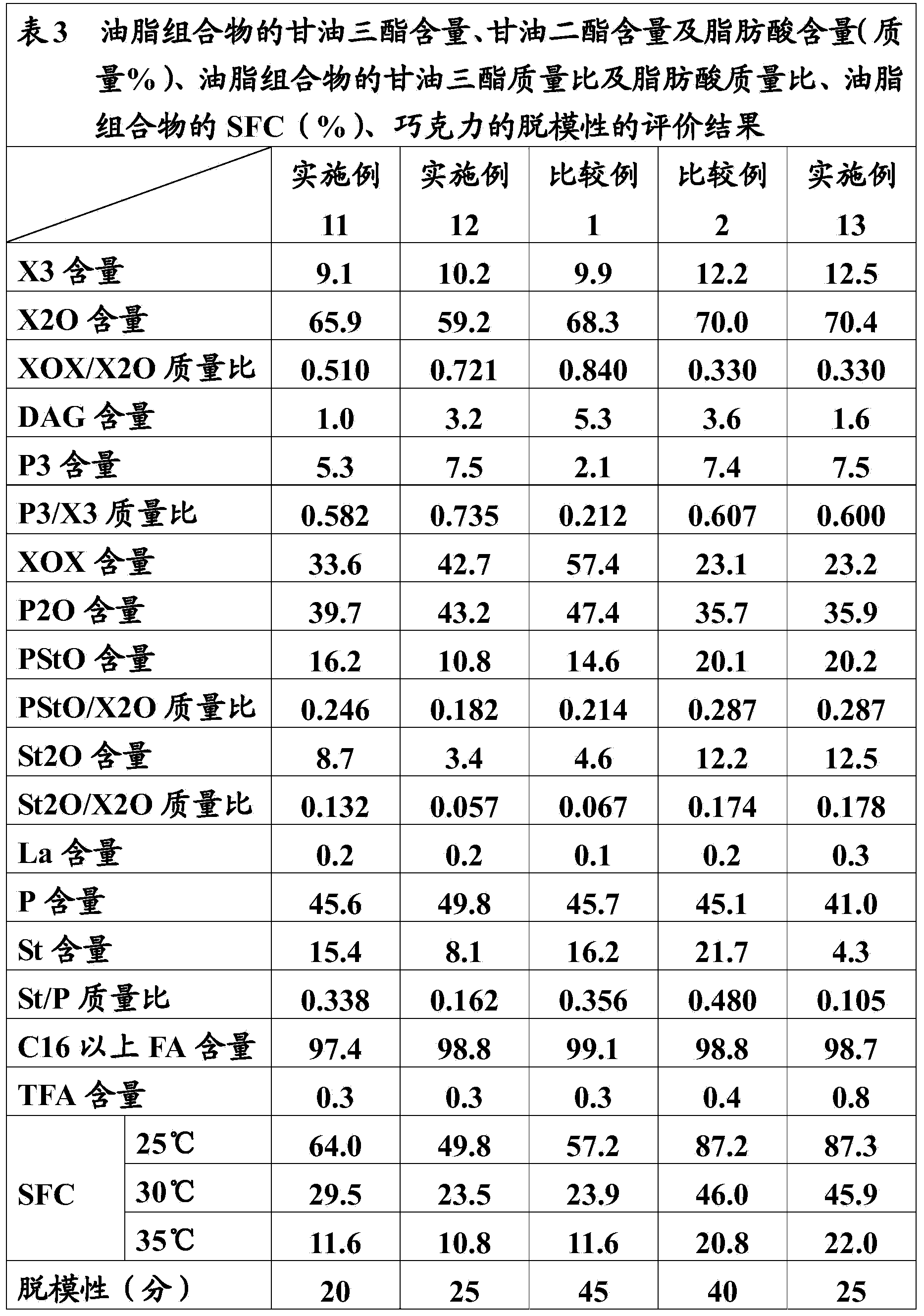

Examples

Embodiment 1

[0145] [Manufacture of the fat composition of Example 1]

[0146] The transesterified oil C was subjected to dry fractionation at 26° C. to obtain a low melting point portion by removing a high melting point portion. The obtained low melting point fraction was subjected to solvent fractionation at 2° C., and the high melting point fraction was obtained by removing the low melting point fraction. The obtained high melting point part is decolorized and deodorized according to a conventional method, and 82 mass parts of this high melting point part, 12 mass parts of hard palm stearin (11.0 by mass) and 6 mass parts of rapeseed oil are mixed to form the grease of embodiment 1 combination.

Embodiment 2

[0147] [Manufacture of the fat composition of Example 2]

[0148] 40 parts by mass of transesterified oil A1 and 60 parts by mass of transesterified oil B were mixed. The obtained mixed oil was subjected to dry classification at 37.8° C. to obtain a low melting point portion by removing a high melting point portion. The obtained low melting point fraction was subjected to solvent fractionation (using acetone) at 0° C., and the high melting point fraction was obtained by removing the low melting point fraction. The obtained high melting point part was decolorized and deodorized according to a conventional method, and it was used as the oil composition of Example 2.

Embodiment 3

[0149] [Manufacture of the fat composition of Example 3]

[0150] 10% by mass of water and 0.1% by mass of lipase (Lipase G "AMANO" 50; manufactured by Amano Enzyme Co., Ltd.) were added to the oil and fat composition of Example 2, and stirred at 43° C. for 6 hours to react. After the lipase treatment, the oil was washed three times with hot water (80° C.) in an amount equal to that of fats and oils to obtain a reaction oil. After adding 1% by mass of clay to the obtained reaction oil, and stirring at 110°C and 500 Pa for 30 minutes, the clay was filtered off to obtain a decolorized oil. The obtained decolorized oil was deodorized at 240° C. and 500 Pa for 90 minutes while blowing water vapor therein, and then used as the oil and fat composition of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com