Cathode for lithium secondary battery and lithium secondary battery containing same

一种二次电池、负极集电体的技术,应用在二次电池、二次电池制造、电池电极等方向,能够解决电池不良率增加、电池循环性能降低、降低电池安全性等问题,达到降低内部短路发生率、电池安全性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

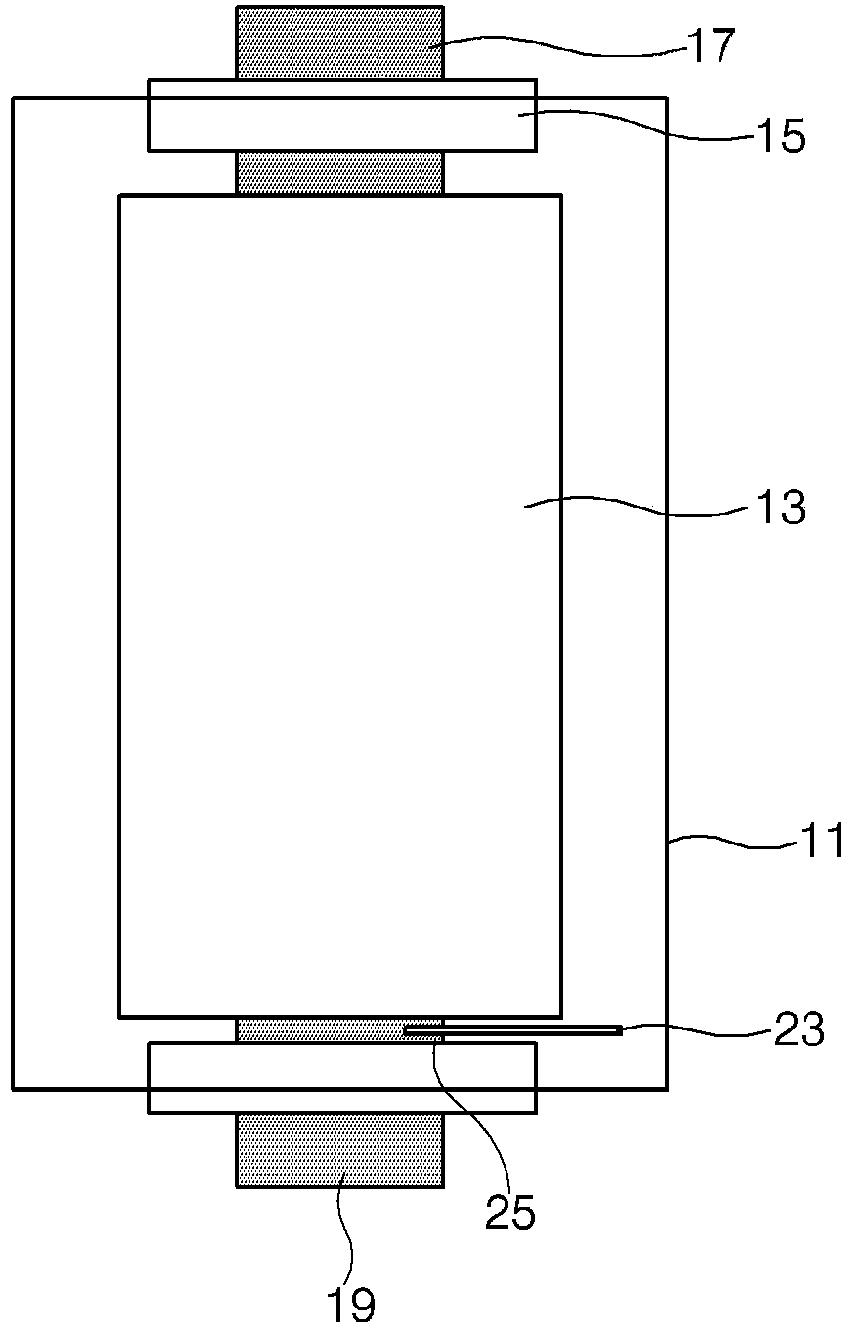

[0046] (Example)

[0047] After preparation of a general positive electrode mixture slurry, coating, drying, and pressure bonding are performed on a long sheet-shaped aluminum foil, whereby a positive electrode sheet is prepared. A negative electrode sheet is prepared by coating, drying, and crimping a common negative electrode active material on a copper foil. The uncoated part of the negative electrode sheet is laser welded to an aluminum metal part. Then, a negative electrode, a separator, a positive electrode, a separator, and a negative electrode are laminated in this order, and then wound up and built into a cylindrical battery case. Inject 1M LiPF into the inside of the battery case 6 Carbonate-based electrolyte, thus preparing a cylindrical battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com