Infrared emitter and NDIR sensor

An infrared detector and infrared technology, applied in instruments, scientific instruments, transmittance measurement, etc., can solve the problems of small infrared radiation propagation distance and low sensor sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

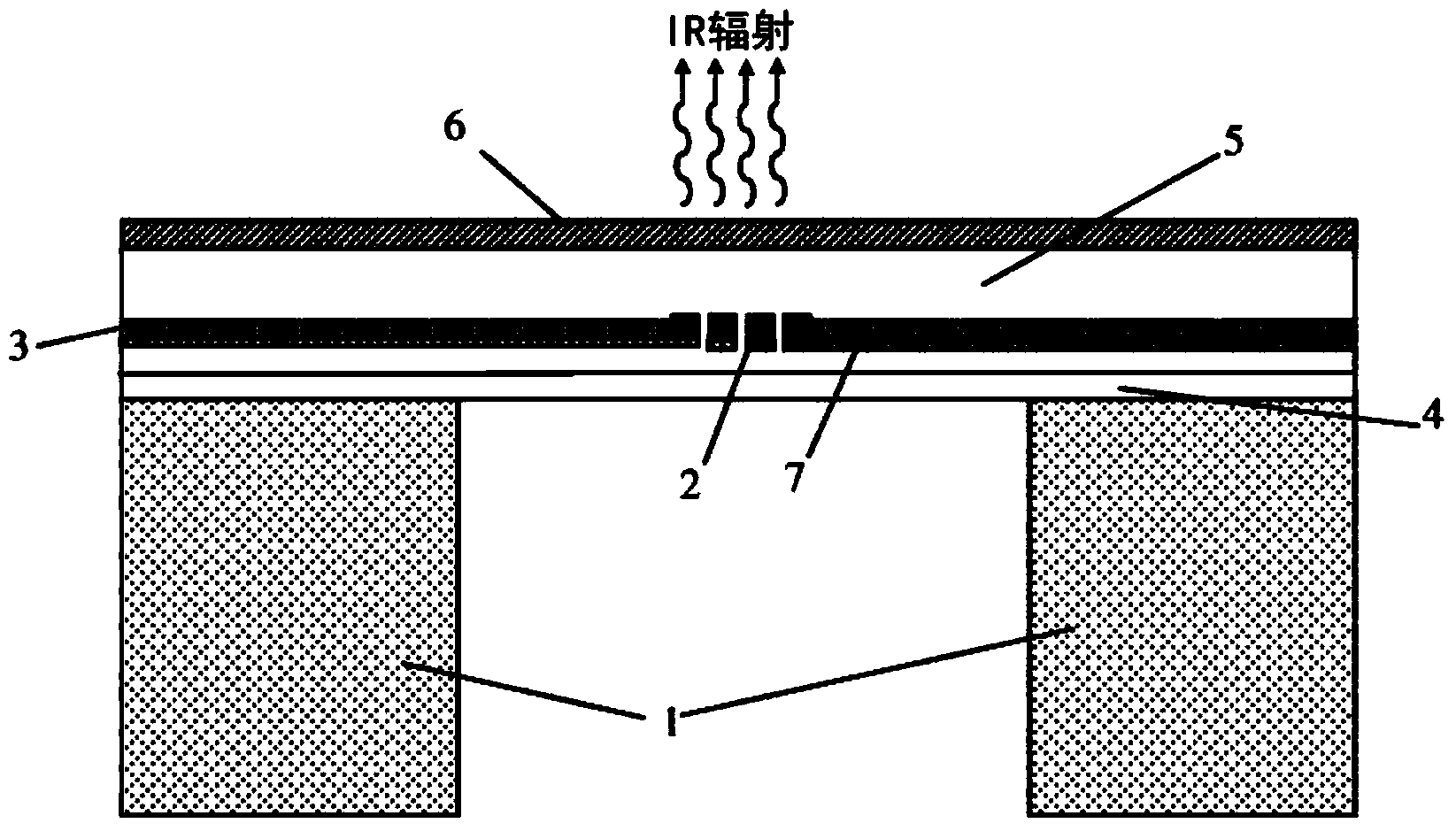

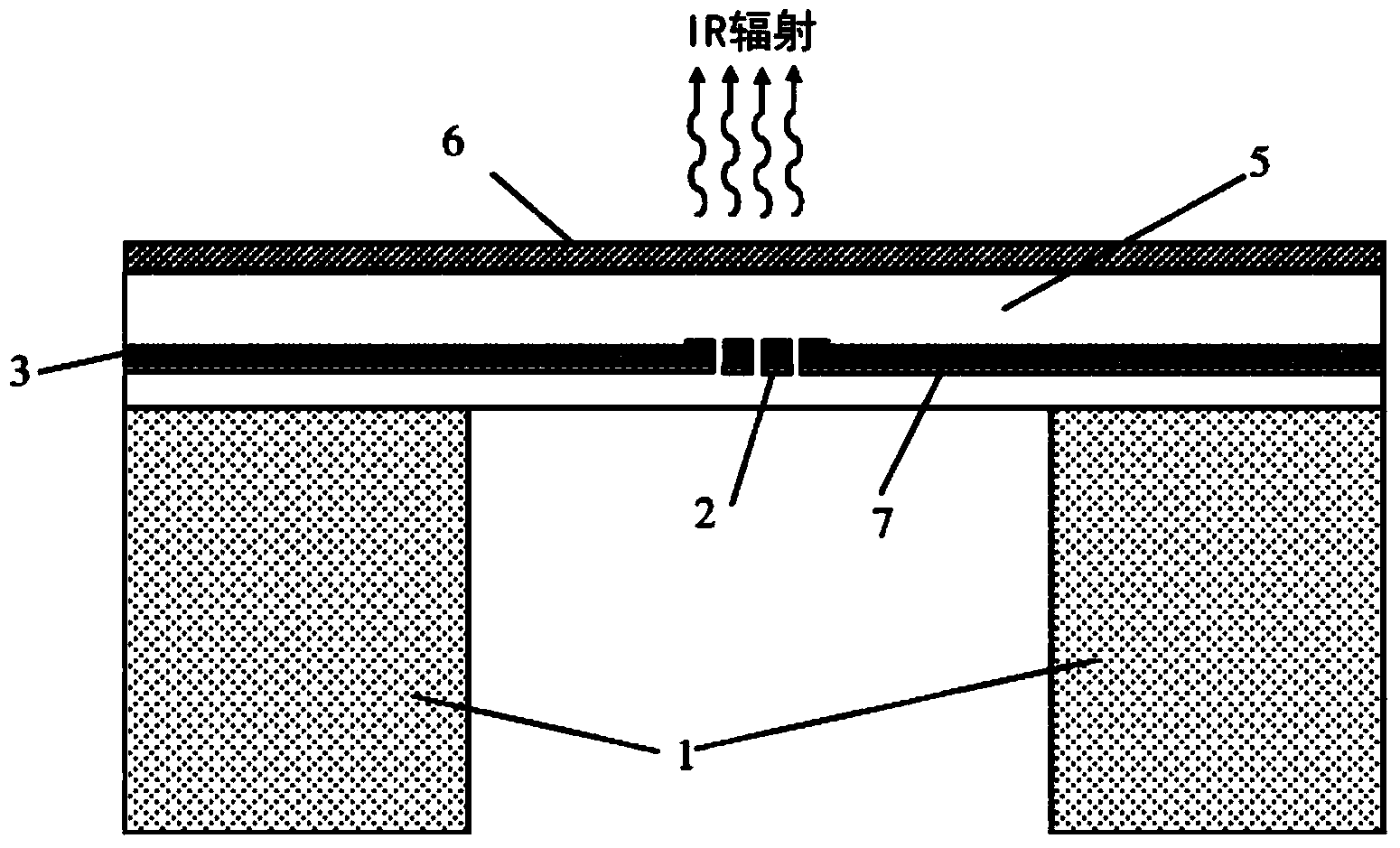

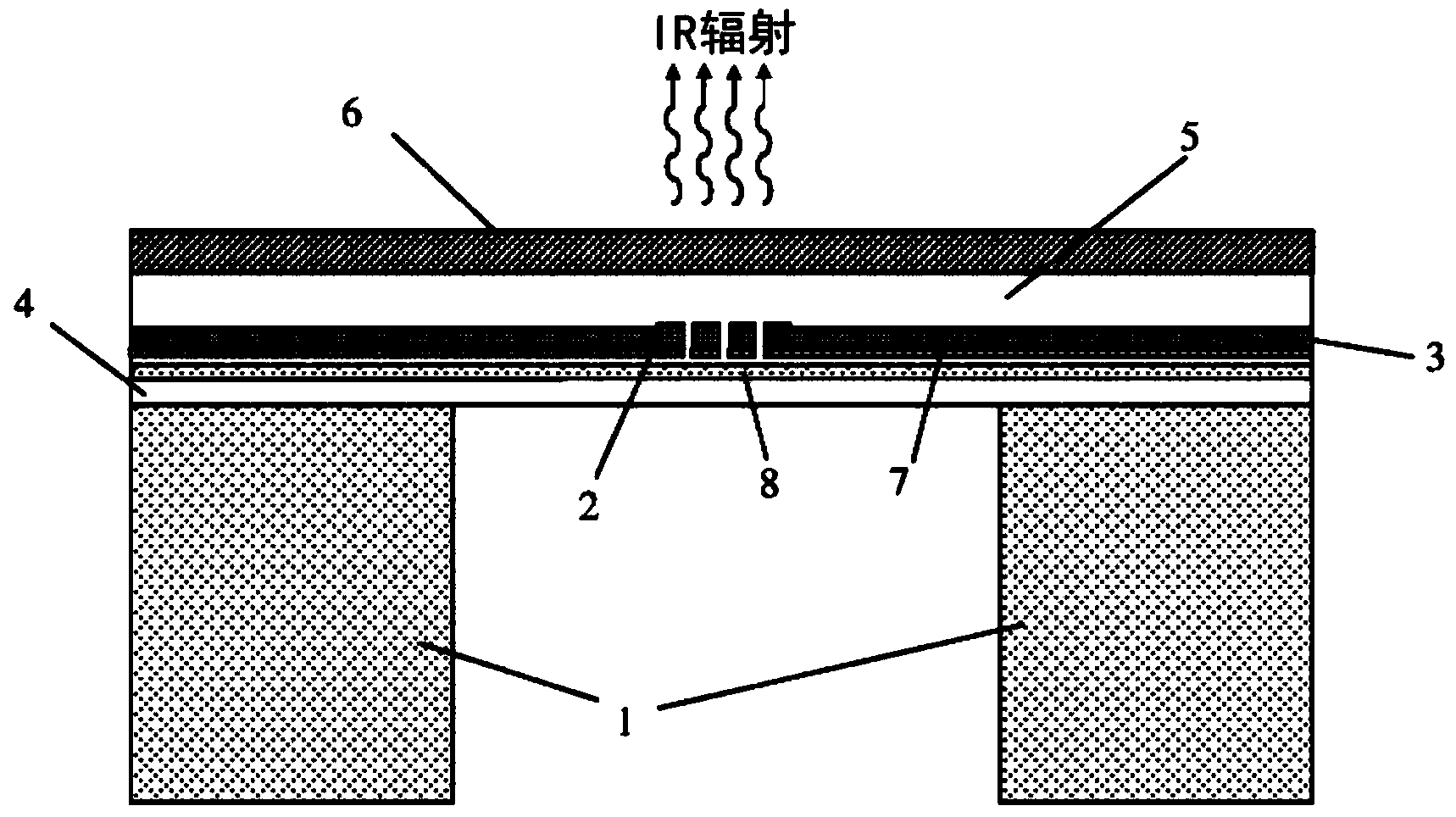

[0058] Embodiments of the present invention seek to facilitate the development of devices in this field by using CMOS layers with tungsten as part of heaters emitting infrared radiation and as interconnect metals for electronic devices. Infrared emitters are embedded in an electrolyte membrane formed by etching a silicon substrate. Etching can be accomplished by deep reactive ion etching (DRIE) techniques. Due to the use of tungsten heaters, this device is capable of reliable operation at high temperatures (well above 600°C). Furthermore, in the CMOS process, the use of tungsten layers ensures high stability, long-term reliability and high reproducibility. CMOS is very different from heaters fabricated by other techniques such as screen printing. To further increase reliability, the tungsten heater can have a titanium / titanium nitride liner. In addition, using CMOS technology to fabricate devices results in lower manufacturing costs and allows circuits to be integrated on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com