Method for grading and separating graphene materials

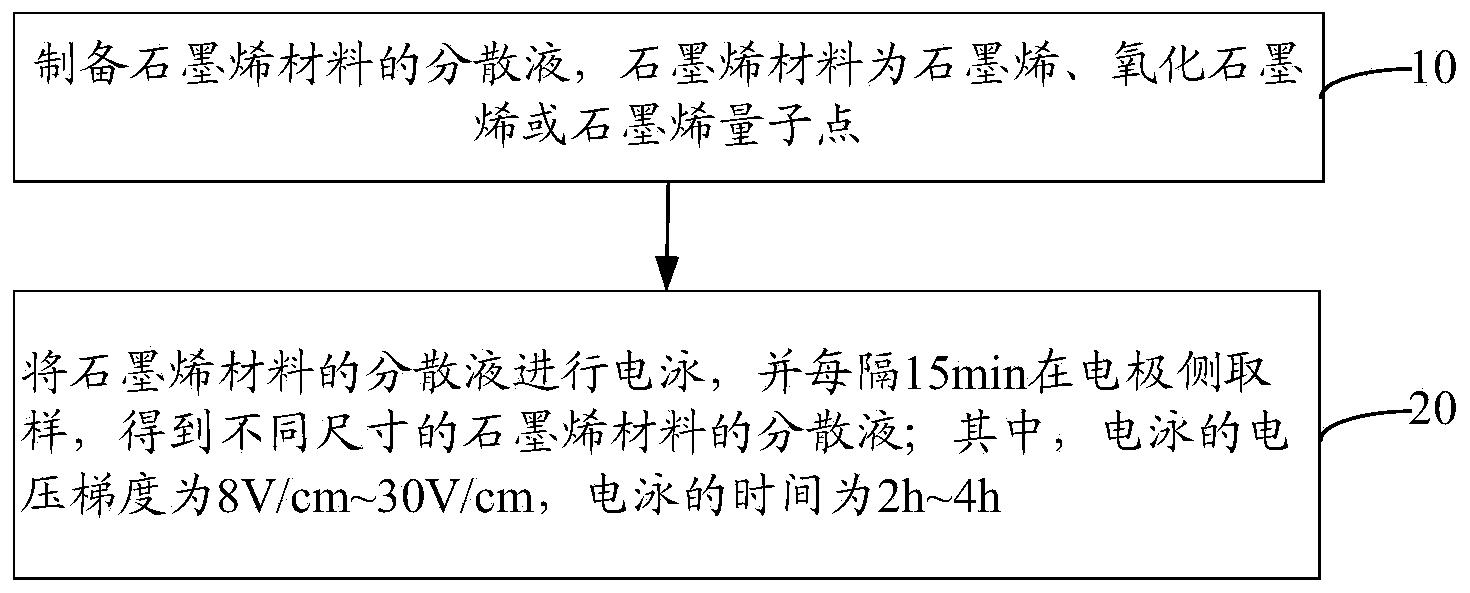

A fractional separation and graphene technology, applied in the field of graphene materials, can solve problems such as difficult to separate graphene of different sizes, inability to effectively separate graphene, small graphene size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] When the graphene material is graphene, the method for preparing the dispersion liquid of the graphene material includes the following steps 110 to 130 .

[0032] Step 110: Prepare an aqueous solution of surfactant.

[0033] The surfactant is added into the deionized water, stirred evenly, and an aqueous solution of the surfactant is prepared. Preferably, in the aqueous solution of the surfactant, the mass percent concentration of the surfactant is 1%-10%. The mass percent concentration of the surfactant is selected as 1% to 10%. On the one hand, it is ensured that sufficient charges are attached to the graphene to facilitate electrophoretic separation; The removal of surfactants can effectively reduce the influence of surfactants on the performance of graphene products, so as to obtain graphene products of various sizes with high quality and narrow size distribution.

[0034] Step 120: adding graphene into the aqueous solution of surfactant, stirring evenly to obtain...

Embodiment 1

[0070] 1. Add tetramethylammonium bicarbonate into deionized water, stir evenly, and prepare an aqueous solution of a surfactant with a mass percent concentration of 1%.

[0071] 2. Add graphene into the aqueous solution of the above-mentioned surfactant, and stir evenly to obtain a mixed solution, wherein the concentration of graphene is 0.1 mg / mL.

[0072] 3. Ultrasonic disperse the above mixed solution under a 120W ultrasonic wave for 6h, then centrifuge at 1500r / min for 3min, take the supernatant to obtain a graphene dispersion; repeat the above step 2 and this step 3 for the precipitate obtained by centrifugation, and continue Prepare graphene dispersions for subsequent electrophoretic separations.

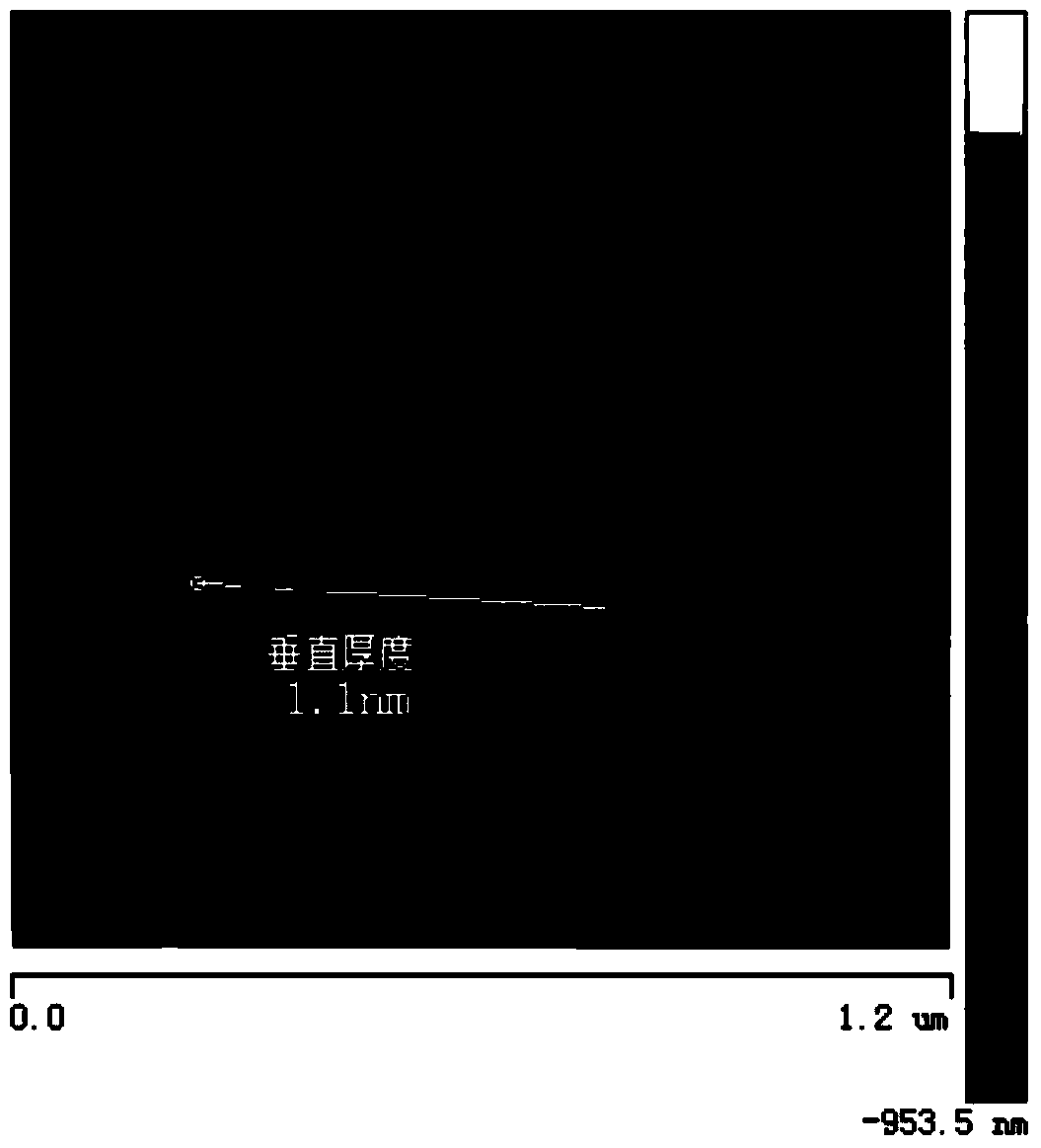

[0073] 4. Conduct electrophoresis on the graphene dispersion, the voltage gradient of the electrophoresis is 8V / cm, and the electrophoresis time is 4h, wherein samples are taken at the electrode side every 15min, each sampling 10mL, to obtain graphene dispersions of different...

Embodiment 2

[0077] 1. Add tetrabutylammonium bicarbonate into deionized water, stir evenly, and prepare an aqueous solution of surfactant with a mass percent concentration of 10%.

[0078] 2. Add graphene into the aqueous solution of the above-mentioned surfactant, and stir evenly to obtain a mixed solution, wherein the concentration of graphene is 1 mg / mL.

[0079] 3. Ultrasonic disperse the above mixed solution under 180W ultrasonic waves for 2h, then centrifuge at 3000r / min for 1min, take the supernatant to obtain a graphene dispersion; repeat the above step 2 and step 3 for the precipitate obtained by centrifugation, and continue Prepare graphene dispersions for subsequent electrophoretic separations.

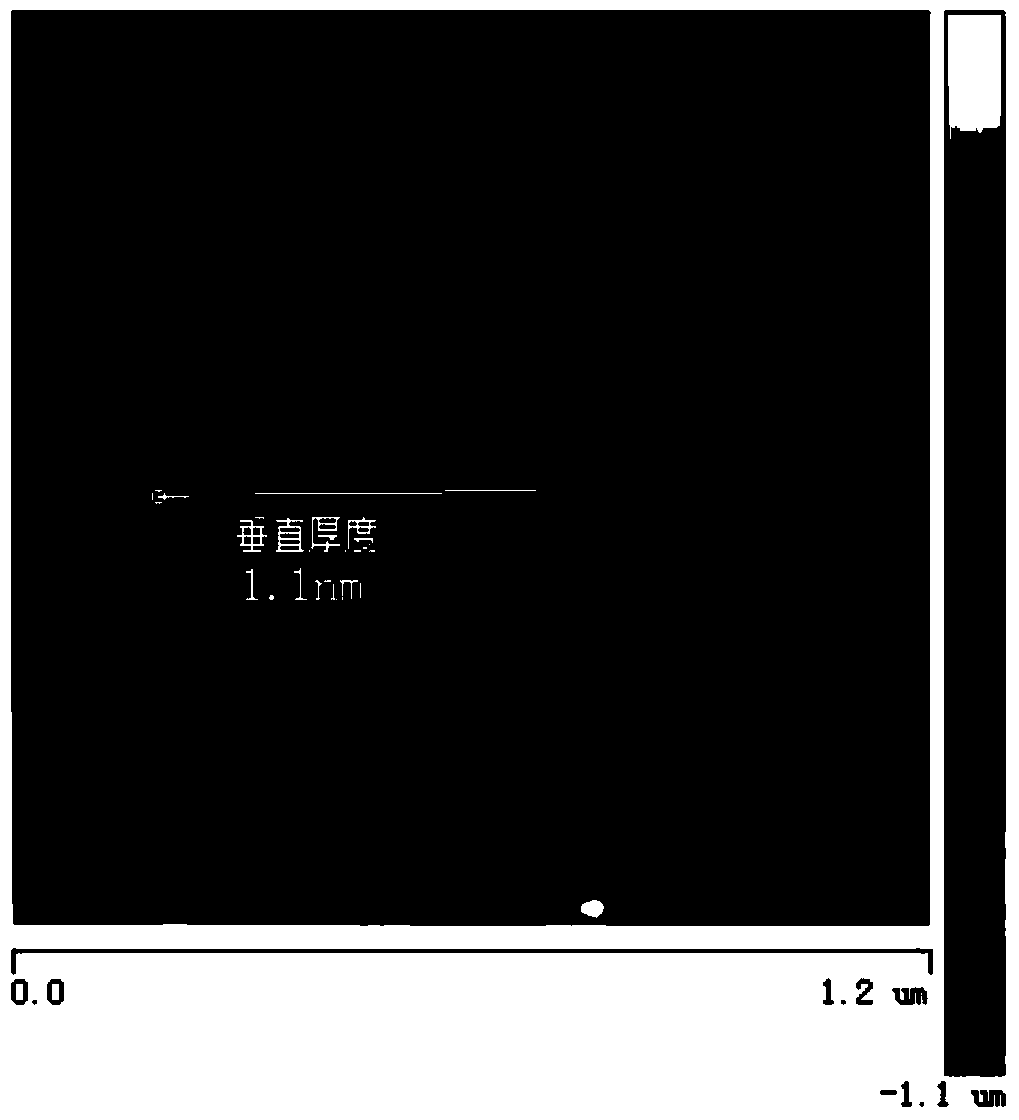

[0080] 4. Conduct electrophoresis on the graphene dispersion, the voltage gradient of the electrophoresis is 30V / cm, and the electrophoresis time is 2h, in which, samples are taken at the electrode side every 15min, and each sampling is 10mL to obtain graphene dispersions of different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com