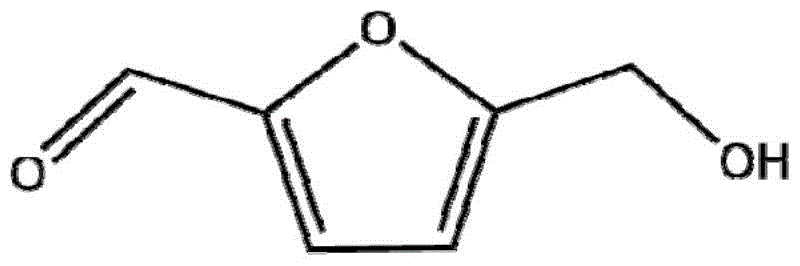

A method for separating and preparing 5-hydroxymethylfurfural from Shengmai Fang

A technology of hydroxymethylfurfural and pulse prescription, which is applied in the field of natural medicinal chemistry, can solve the problems of separation and preparation efficiency and product purity, and increase the difficulty of 5-hydroxymethylfurfural, so as to achieve easy control of operating process conditions and ensure safety The effect of sex and process method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) The composition of Shengmai Fang in this embodiment is: Codonopsis 300g, Ophiopogon japonicus 200g, Schisandra chinensis 100g, the above three flavors are crushed into coarse powder, decocted twice with water, each decocting 2h, the amount of water used for the two times is 3200mL respectively , 2400mL. The extracts were combined and filtered, and the filtrate was concentrated to obtain a viscous extract containing 5-hydroxymethylfurfural.

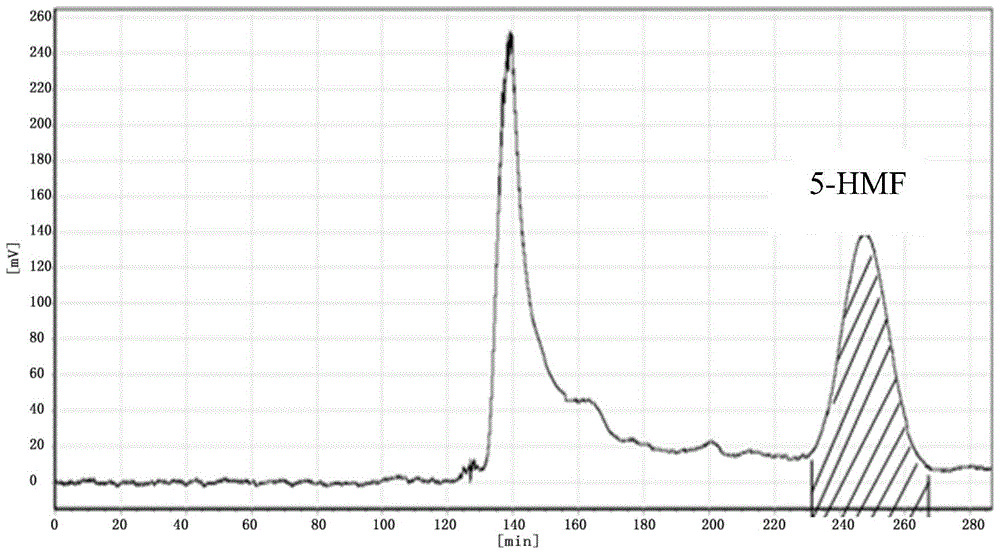

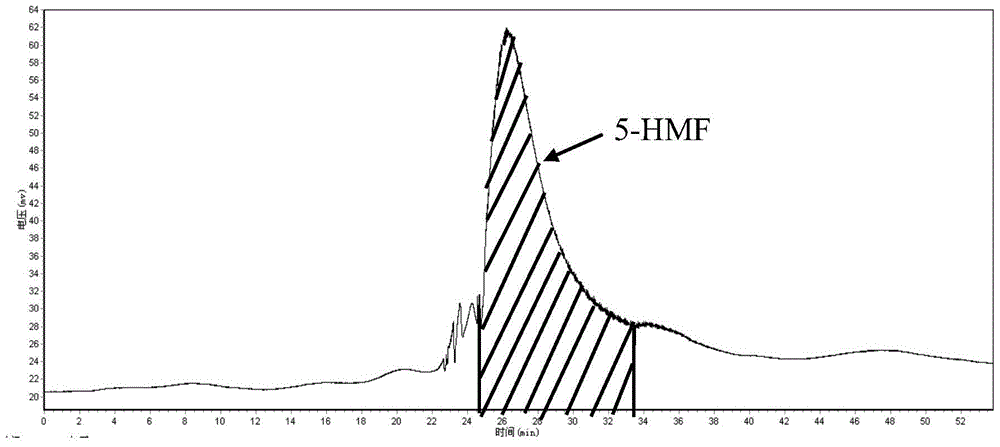

[0037] (2) Get the pretreated D-101 type macroporous resin and pack it into a glass column. The column volume is 23mL, and the crude extract obtained in step (1) is loaded into the sample, and the loading amount is 20g. After adsorption, first Remove impurities with 125 mL of water (about 5 times the column volume), then elute with 200 mL of 30% ethanol-water solution (about 8 times the column volume) at a flow rate of 1 mL / min, collect the eluate in separate tubes, identify by liquid chromatography, and combine The eluate cont...

Embodiment 2

[0041] (1) Get the pretreated AB-8 type macroporous resin and pack it into a glass column. The column volume is 20mL. The crude extract obtained from step (1) in Example 1 is loaded into the sample, and the sample size is 12g. Finally, remove impurities with 100 mL of water (about 5 times the column volume), then elute with 160 mL of 30% ethanol-water solution (about 8 times the column volume) at a flow rate of 1 mL / min, collect the eluate in separate tubes, and perform liquid chromatography Identify, combine the eluate containing 5-hydroxymethylfurfural, and concentrate the eluate to obtain 0.193 g of macroporous resin enrichment. Wherein, the detection condition of liquid chromatography is the same as embodiment 1.

[0042] (2) Using medium-pressure preparative chromatography to separate and purify the macroporous resin enrichment obtained in step (1). Use reversed-phase silica gel C18 column (23*4.9cm i.d.), take 496.9mg of the macroporous resin enrichment obtained in step...

Embodiment 3

[0044] (1) The composition of Shengmai Fang in this example is: 300g ginseng, 300g Ophiopogon japonicus, 200g schisandra, the above three flavors are crushed into coarse powder, decocted twice with water, each decocting 2h, the amount of water used for the two times is 4000mL respectively , 3000mL. The extracts were combined and filtered, and the filtrate was concentrated to obtain a viscous extract containing 5-hydroxymethylfurfural.

[0045] (2) Get the pretreated D-101 type macroporous resin and pack it into a glass column, the column volume is 25mL, and the crude extract obtained in step (1) is loaded into the sample, and the loading amount is 20g. After adsorption, first Remove impurities with 125 mL of water (about 5 times the column volume), then elute with 200 mL of 30% ethanol-water solution (about 8 times the column volume) at a flow rate of 1 mL / min, collect the eluate in separate tubes, identify by liquid chromatography, and combine The eluate containing 5-hydroxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com