High temperature resistant micro-foam drilling fluid

A technology of high temperature resistance and drilling fluid, applied in the field of petroleum drilling fluid, can solve the problems of complex implementation process, reservoir damage, high cost, and achieve the effects of good rheology, ability to reduce hydration, and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

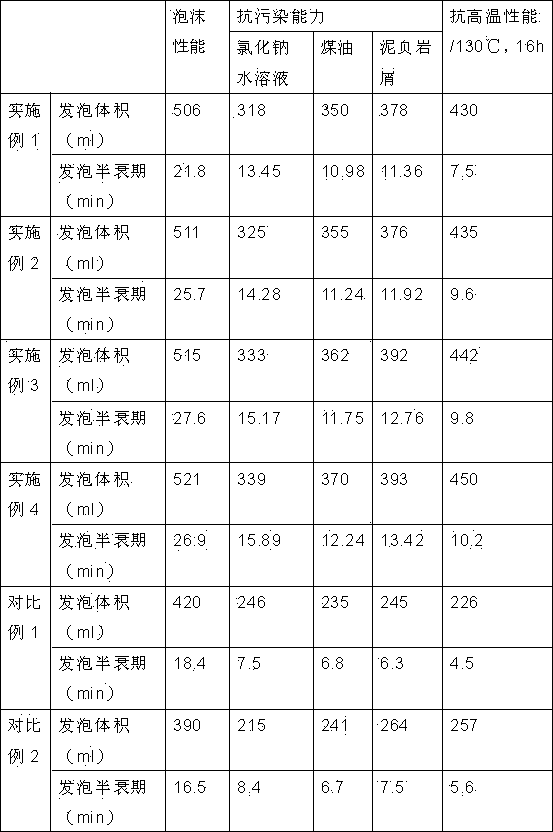

Examples

Embodiment 1

[0017] A high temperature resistant microfoam drilling fluid, comprising the following components in parts by weight: 10 parts of modified attapulgite, 4 parts of sodium α-alkenyl sulfonate, 0.5 parts of nano titanium dioxide, 1 part of tea saponin, nano 0.2 parts of molybdenum disulfide, 0.4 parts of nano zirconium dioxide, 3 parts of sulfonated phenolic resin, 1 part of polyquaternium salt, and 100 parts of water.

[0018] The preparation method of the modified attapulgite is to first place the attapulgite in NaOH with a concentration of 10% and soak it for 3 hours, then place it in an aqueous solution of HCl with a concentration of 13% for 2 hours, filter, and take the filter residue , washed with water until neutral and dried, then activated at 400°C for 3 hours.

[0019] The preparation method of the high-temperature resistant micro-foam drilling fluid of the present invention is to use a conventional physical stirring method to stir and mix all the raw materials in the a...

Embodiment 2

[0021] A high temperature resistant microfoam drilling fluid, comprising the following components in parts by weight: 15 parts of modified attapulgite, 6 parts of sodium α-alkenyl sulfonate, 2 parts of nano titanium dioxide, 3 parts of tea saponin, nano 0.5 parts of molybdenum disulfide, 0.7 parts of nano zirconium dioxide, 5 parts of sulfonated phenolic resin, 2 parts of polyquaternium salt, and 130 parts of water.

[0022] The preparation method of the modified attapulgite is to soak the attapulgite in NaOH with a concentration of 12% for 3 hours, then place it in an aqueous solution of HCl with a concentration of 15% for 3 hours, filter, and take the filter residue , washed with water until neutral and dried, placed at 450 ° C high temperature activation for 5 hours, that is.

[0023] The preparation method of the embodiment of the present invention is the same as that of embodiment 1.

Embodiment 3

[0025] A high temperature resistant microfoam drilling fluid, comprising the following components in parts by weight: 12 parts of modified attapulgite, 5 parts of sodium α-alkenyl sulfonate, 1 part of nano titanium dioxide, 2 parts of tea saponin, nano 0.3 parts of molybdenum disulfide, 0.6 parts of nano zirconium dioxide, 4 parts of sulfonated phenolic resin, 1.8 parts of polyquaternium salt, and 120 parts of water.

[0026] The preparation method of the modified attapulgite is to place the attapulgite at a concentration of 11% and soak it in NaOH for 3 hours, then place it in an aqueous solution of 14% HCl for 2.3 hours, filter, and take The filter residue was washed with water until neutral and dried, and activated at 420°C for 3.5 hours to obtain the final product.

[0027] The preparation method of the embodiment of the present invention is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com