A kind of ozone process machine and the method for using it to carry out clothing fading treatment

An ozone and process technology, used in fiber processing, textile material processing, textile material container processing, etc., can solve the problems of loose and twisted ozone hoses, affecting ozone filling, uneven fading, etc., to improve processing capacity and Efficiency, improved waiting time, uniform effect of fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

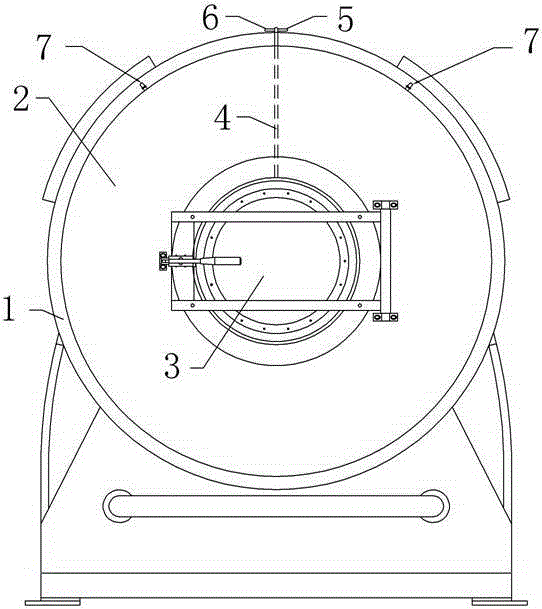

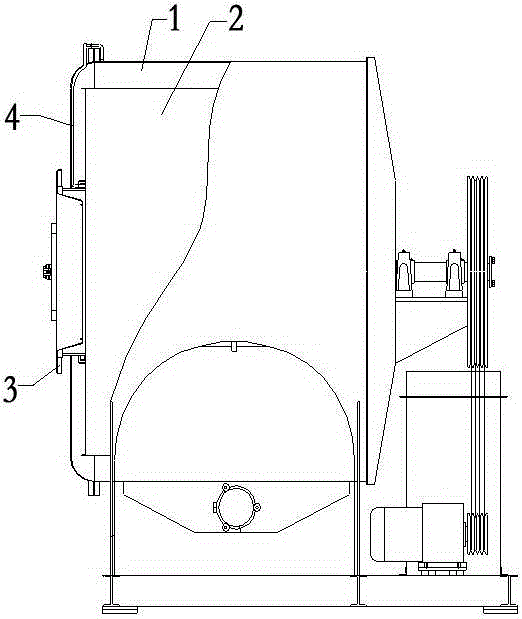

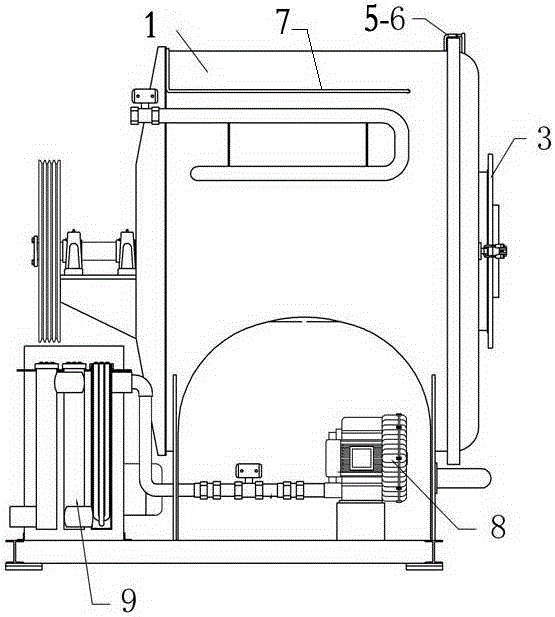

[0016] A kind of ozone technology machine, comprises fuselage 1, the drum 2 that places clothes in the fuselage, the machine door 3 that seals the inner space of the fuselage, is provided with the ozone tube 4 on the fuselage, and the end of the ozone tube leads to the rotating drum. At the upper position of the drum mouth, the fuselage is also provided with an auxiliary pipeline for passing high-pressure gas into the drum. When coloring clothes, first put the clothes or fabrics into the drum, close the sealable machine door; then, drive the loading drum to rotate, and fill the drum with the required liquid from the upper position of the drum mouth through the ozone tube. Ozone, the high-pressure gas that the auxiliary pipeline fills into the drum; the ozone tube and the auxiliary pipeline fill the drum with ozone and high-pressure gas alternately.

[0017] The ozone pipe and the auxiliary pipeline can be the same air intake pipe, and the air intake pipe is provided with two g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com