Thermal spinning film deaerator

A deaerator, membrane technology, applied in the field of thermal spin film deaerator, can solve the problems of energy waste, exhaust noise, etc., and achieve the effect of expanding the contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

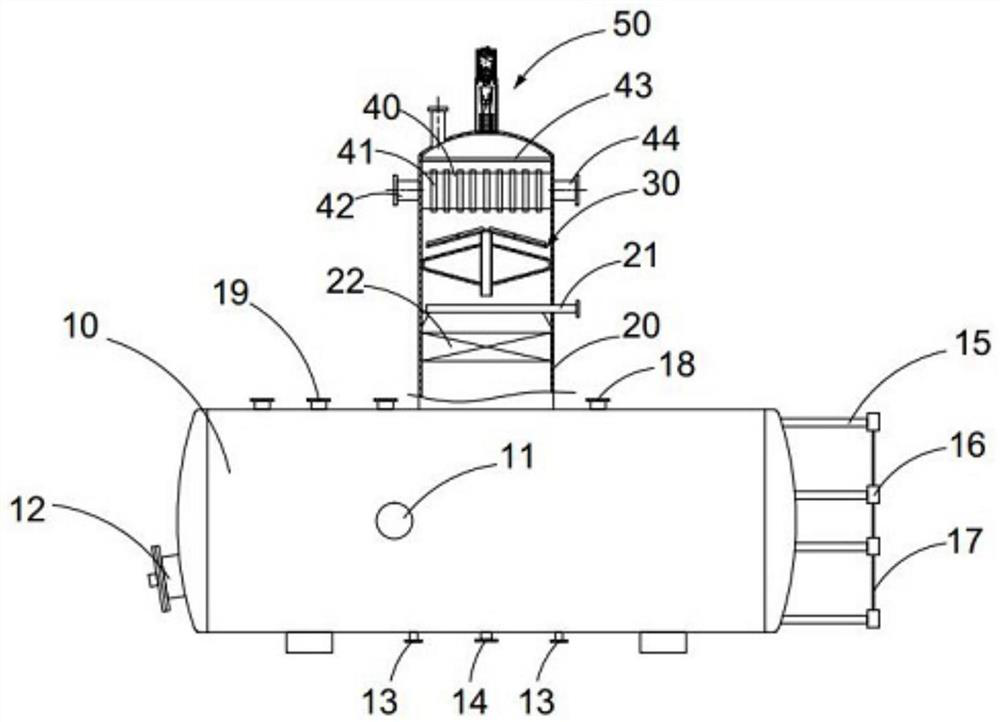

[0037] See attached Figure 1-10 As shown, the thermal rotary film deaerator includes:

[0038] The first oxygen removal housing 10, the first oxygen removal housing 10 is placed horizontally;

[0039] The second deaeration housing 20, the second deaeration housing 20 is placed vertically and is arranged on the top of the first deaeration housing 10, the first deaeration housing 10 and the second deaeration housing 20 are hollowly arranged inside and connected;

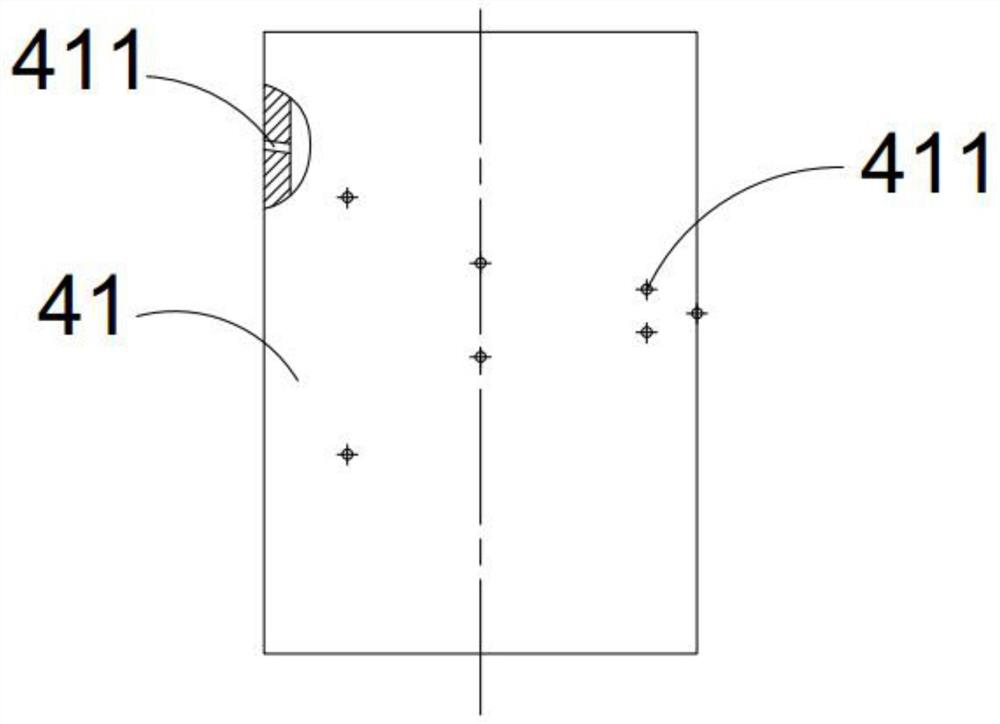

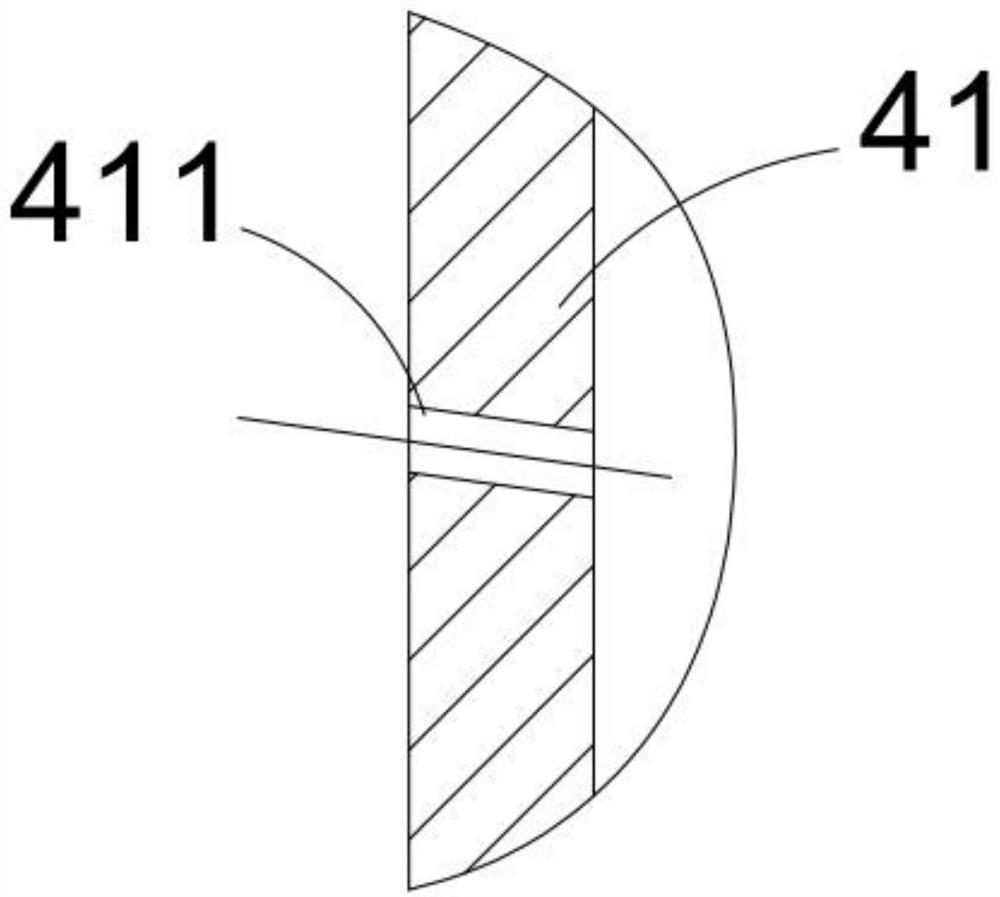

[0040] The upper part of the second deaeration housing 20 is provided with a water chamber 40, and the second deaeration housing 20 on both sides of the water chamber 40 is respectively connected with the first water supply inlet 42 and the second water supply inlet 44. The provided nozzle 41, the upper and lower ports of the nozzle 41 are all arranged on the outside of the water chamber 40, the surface of the nozzle 41 is spirally arranged with water inlet holes 411, and the upper end of the second deaeration housi...

Embodiment 2

[0051] The further optimization scheme of present embodiment on the basis of embodiment 1 is: see appendix Figure 11-13 As shown, the first deaeration housing 10 is provided with a limit box 70, the upper end of the limit box 70 is connected to the inner upper wall of the first deaeration housing 10, and the lower end of the limit box 70 is connected to the first deaeration housing. 10, the inner lower wall is connected, the limit box 70 lower side wall is provided with a water inlet through hole 71, the limit box 70 is provided with a buoyancy member 72, the limit box 70 upper side wall is connected with a communication base 74, communicates A limit cavity 79 is provided in the base part 74, and a fourth air delivery hole 78 that passes through the base part 74 is also provided on the communication base part 74, so that the gas is passed into the limit box 70, and the communication base part 74 passes through the pipe body. Connect with the tee pipe 76, the other mouth of th...

Embodiment 3

[0053] The further optimization plan of this embodiment on the basis of Embodiment 1 is as follows: a water retaining plate 43 is provided above the water chamber 40, through holes or mesh holes are arranged on the surface of the water retaining plate 43, and a thermometer is provided outside the first deaeration housing 10 11. The detection probe of the thermometer 11 is set in the first deaeration housing 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com