Crystal grain size ultrasonic non-destructive evaluation method without thickness measurement

A technology of grain size and evaluation method, applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc., can solve problems such as reducing practicability, increasing inspection cost and inspection man-hours, affecting the accuracy of grain size, etc., to ensure operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

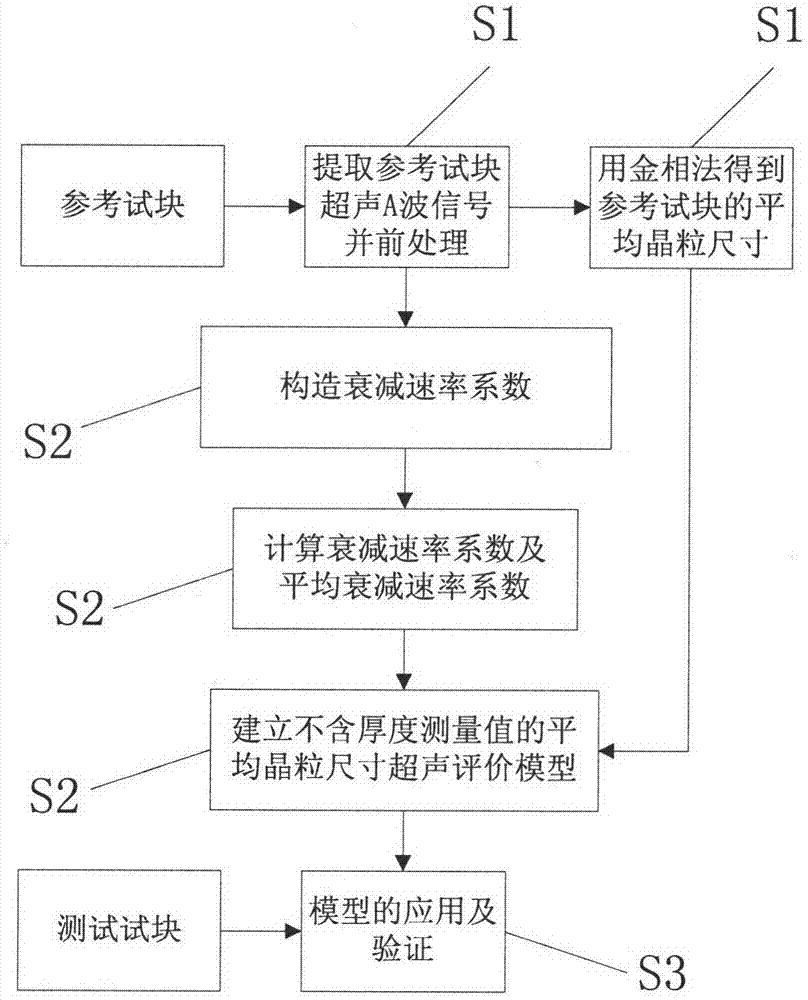

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

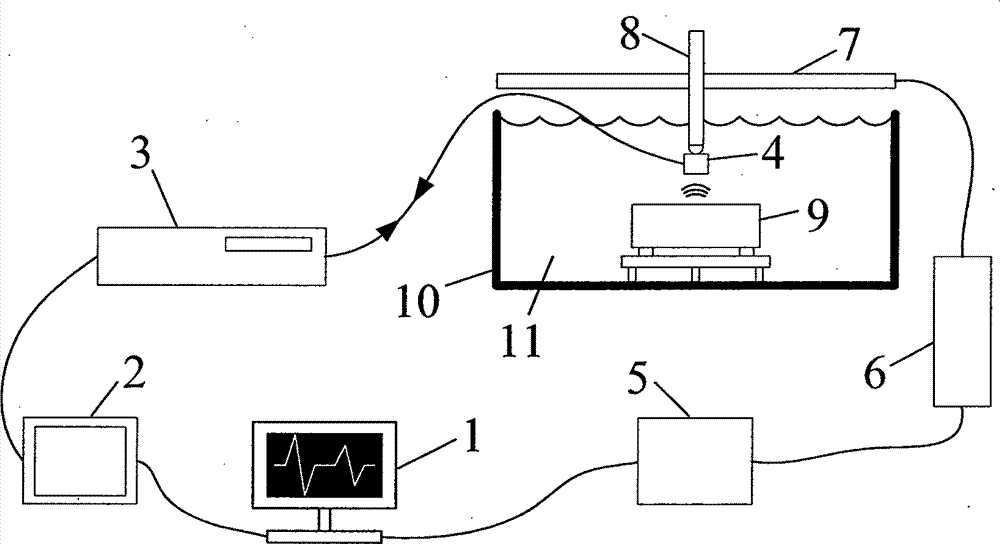

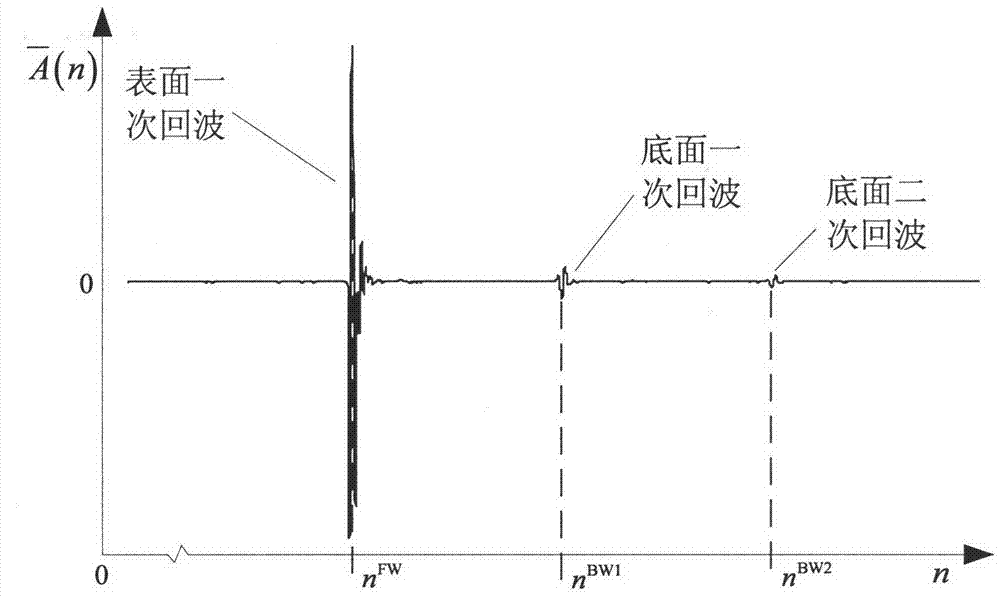

[0053] This specific embodiment takes TP304 stainless steel as an example. In order to evaluate a test block with an unknown average grain size, it is necessary to use several reference test blocks with known average grain sizes to establish an evaluation model. In the present invention, the reference test block is firstly fixed in a water tank filled with water, and the ultrasonic pulse generator / receiver (also known as ultrasonic instrument) is used to excite the ultrasonic longitudinal wave probe, and the ultrasonic longitudinal wave probe is clamped on the six-degree-of-freedom motion platform through the probe frame, Connect the control circuit through the motion control card installed on the computer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com