Equipotential optical fiber unit for high-voltage photoelectric composite cable and manufacturing method thereof

A technology for optoelectronic composite cables and optical fiber units, which is applied to power cables, power cables, electrical components, etc. including optical transmission components, can solve problems such as insecurity of personnel and equipment, breakdown of protective layers, and impact on the service life of optical fiber units. Achieve the effect of improving service life and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

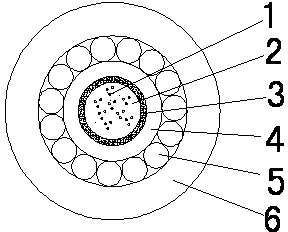

[0022] The equipotential optical fiber unit 1 for high-voltage photoelectric composite cable of the present invention consists of optical fiber 1, special water-blocking ointment 2 for filling the optical fiber unit, metal protection tube 3, semi-conductive plastic reinforcement layer 4, and metal wire armor layer 5 from inside to outside. Composed of a semi-conductive plastic outer sheath 6, the optical fiber unit is filled with a special water-blocking ointment 2, the metal protection tube 3 is one of copper tape, 314 stainless tape, and 316L stainless tape, and the semi-conductive plastic reinforcement layer 4 is a semi-conductive plastic One of conductive low-density polyethylene and semi-conductive medium-density polyethylene. The metal wire armor layer 5 is twisted from high-strength steel wires. The semi-conductive plastic outer sheath 6 is semi-conductive low-density polyethylene and semi-conductive medium-density polyethylene. One of the density polyethylene.

[0023]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pay-off tension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com