Modeling method for determining optimum mandril movement limiting speed in seamless steel tube production process

A technology of limiting speed and production process, which is applied in the modeling field of determining the optimal limiting speed of mandrel in the production process of seamless steel pipe, which can solve the complex calculation of the maximum limiting speed of mandrel, which is unfavorable for the steel pipe rolling industry. and other problems to achieve the effect of improving service life and product quality, avoiding production risks, and reducing mandrel wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

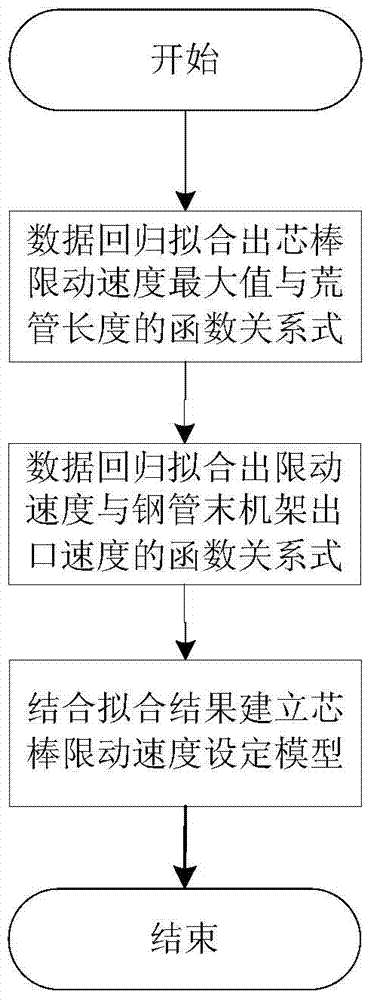

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The specific implementation steps of the present invention are illustrated by taking the model for setting the maximum value of the mandrel limit speed when the outer diameter of the mandrel is 187mm as an example.

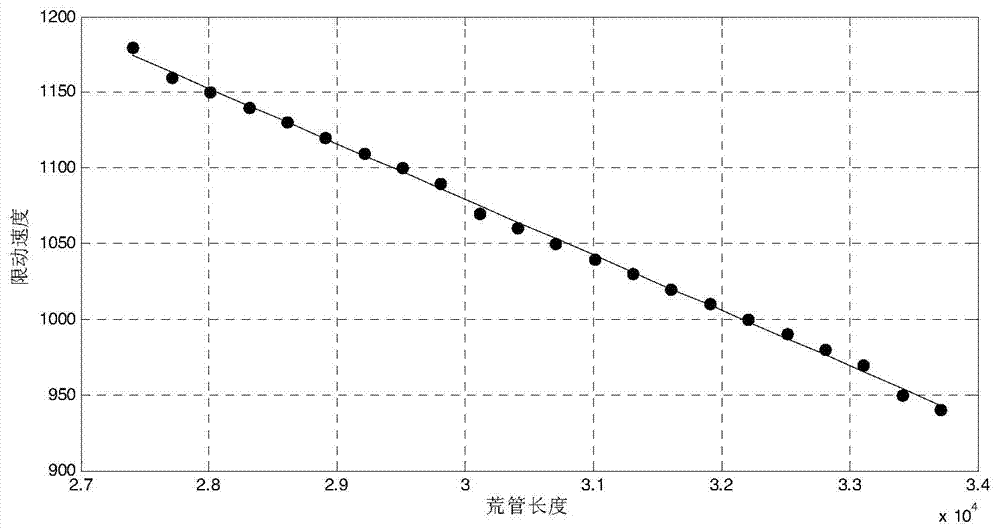

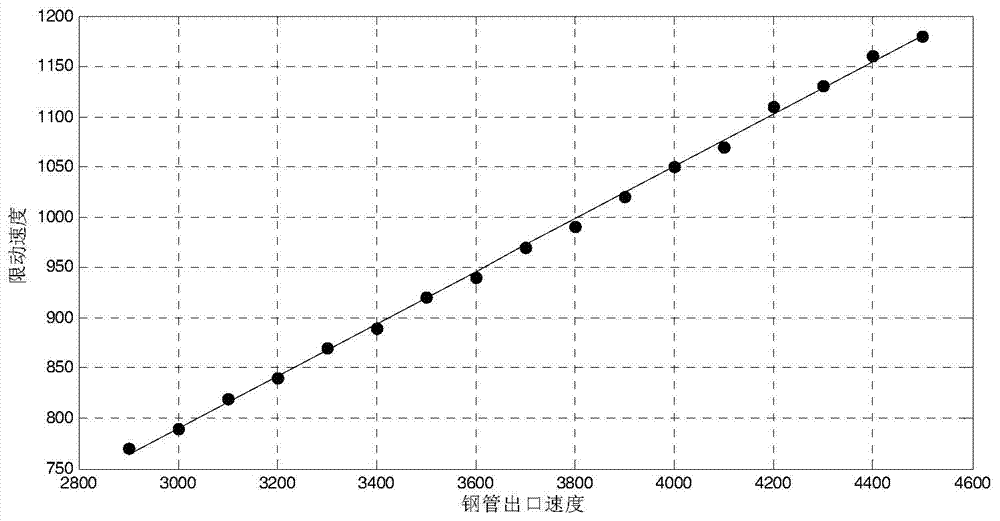

[0034]In actual production, the factors affecting the maximum set value of the mandrel limit speed include the length of the blank pipe and the exit speed of the end frame of the steel pipe. It can be known from process knowledge and experience that the longer the length of the blank pipe, the smaller the maximum limit speed of the mandrel should be set, and the greater the exit speed of the steel pipe, the greater the maximum limit speed of the mandrel should be set. According to the process setting and on the premise of ensuring smooth production, the calculation process is as follows:

[0035] Step 1: Taking the batches whose rolling plan is 235mm in capillary outer diameter, 16mm in wall thickness, 199.54mm in barren tube in outer diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com