An Uncertainty Judgment Method for Passive Waste Heat Removal System

A passive waste heat and uncertainty technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of high sampling cost, reduce the accuracy of safety judgment of passive waste heat removal system, and cannot quickly judge, etc. problems, to achieve the effect of improving sampling efficiency, avoiding errors, and quickly judging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below by example the present invention is described in further detail:

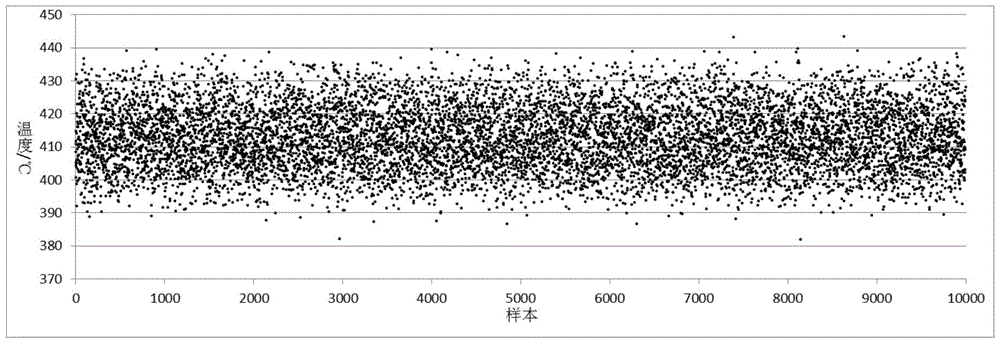

[0029] Usually, the failure rate of the event studied is low. It is a small probability event to randomly sample the failure sample points. Most of the sample points obtained by sampling are distributed in the non-failure range. The region has very high accuracy, but the fitting accuracy of the failure region which is most concerned by the present invention is too low.

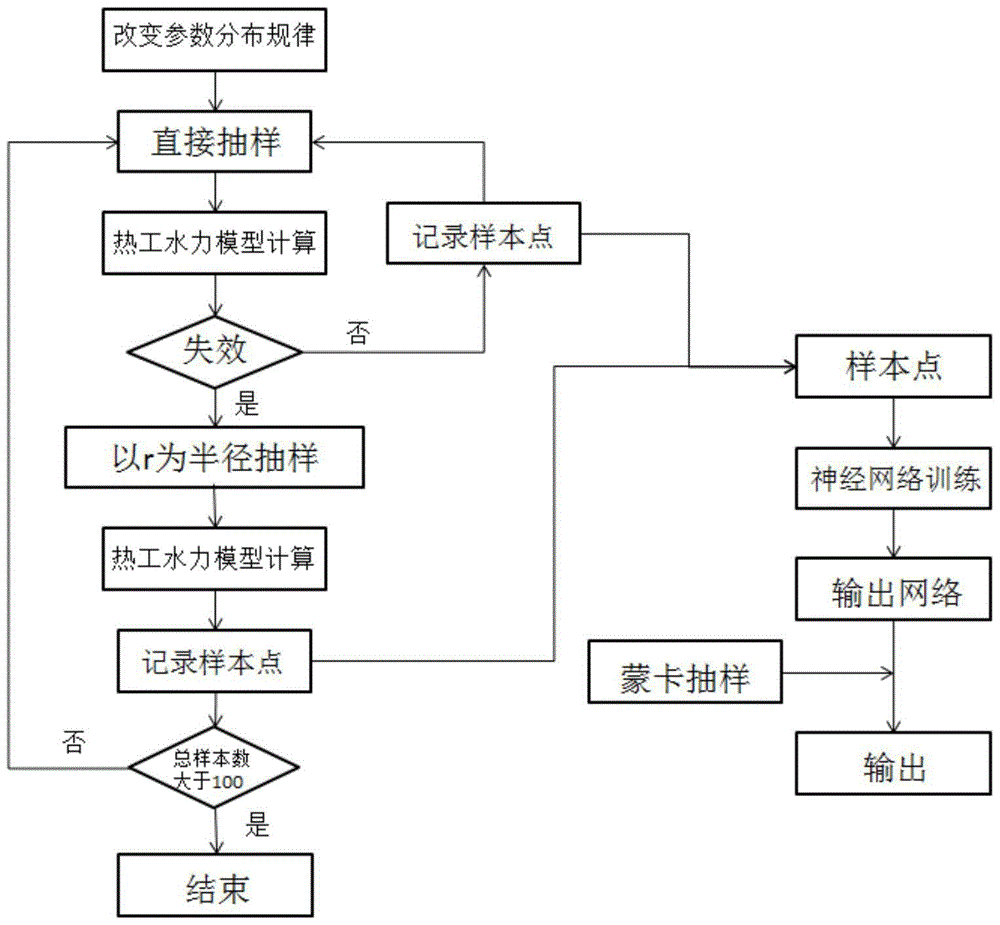

[0030] The technical solution of the present invention: the present invention overcomes this problem by changing the distribution law of the input variable. When sampling, the distribution law of the input variable is changed, but the value range is not changed. For example, all normal distributions are changed to uniform distribution, which increases the probability of occurrence of both ends of the value range. This only changes the probability of occurrence of each sample point, and does not change the functional relationship be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com