Flame-retardant battery box and flame-retardant power battery system

A power battery and battery box technology, applied in the field of power battery modules, can solve the problems of power battery system control devices, battery pack corrosion cost, and complicated wiring, etc., and achieve the effect of light weight, low cost, and simplified wiring connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The flame-retardant battery box and the flame-retardant power battery system provided by the present invention will be described in detail below through embodiments with reference to the accompanying drawings.

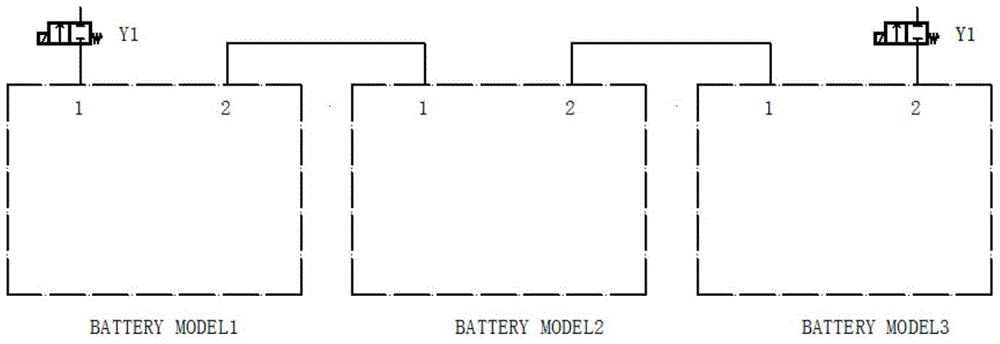

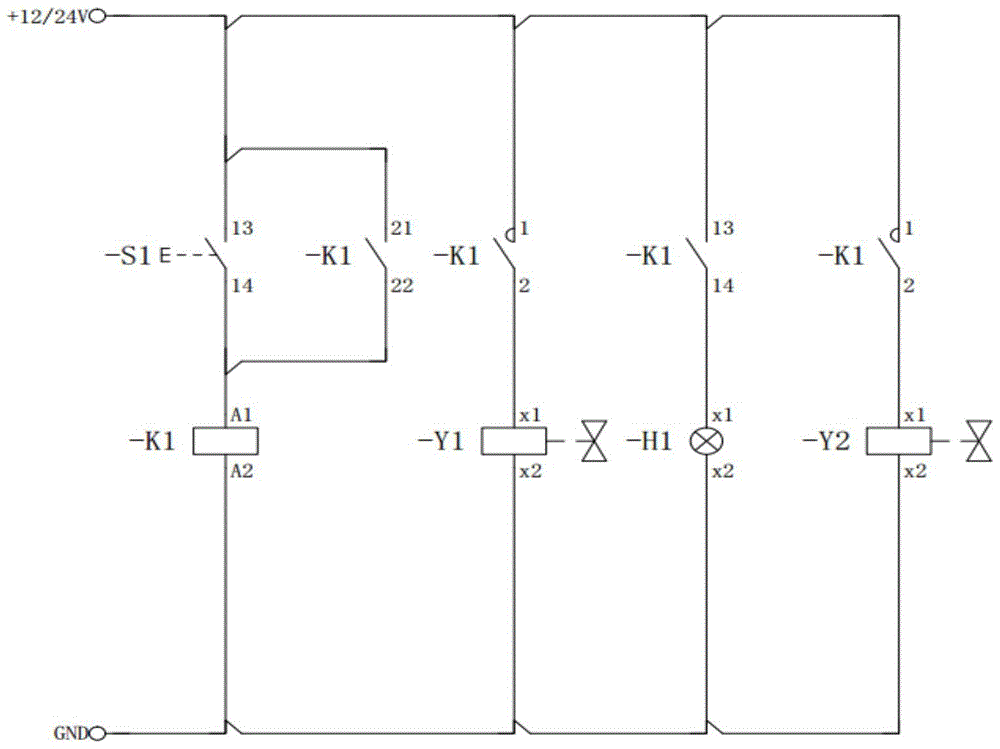

[0024] Such as figure 1 Shown is a specific embodiment of the present invention. The new energy vehicle power battery system includes 3 independent power battery modules, and each module contains several single batteries. Each power battery module is placed in a gas-tight flame-retardant battery box to isolate the power battery module from contact with the outside air. The battery box is filled with other flame retardant gases such as nitrogen or carbon dioxide to reduce the oxygen content in the box so as to eliminate the conditions for the thermal runaway of the battery pack to cause combustion. The box body is provided with a power interface and a control interface, both of which are airtight electrical connectors. Each battery pack in the box is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com