Semiconductor laser device with stable wavelength and manufacturing method thereof

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of complex technology and high cost, and achieve the effect of reducing wavelength drift, reducing coefficient, structure and manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is the manufacture of TO packaged lasers (including TO56, TO9, etc.), including the following steps:

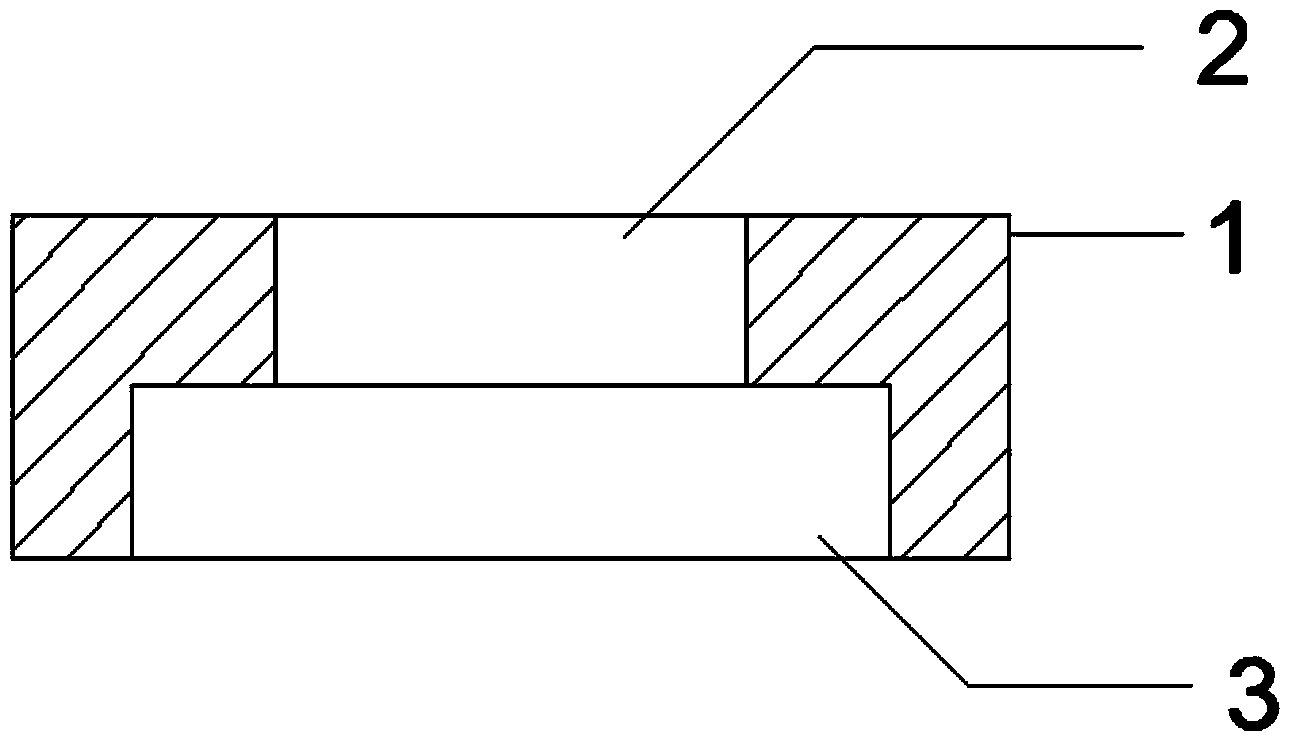

[0024] (1) production figure 1 As shown in the metal base 1 , the base plate is circular or square in shape, with a coaxial large hole 3 and a small hole 2 inside, and the large hole 3 and the small hole 2 form a stepped hole. The diameter of the large hole 3 is slightly smaller than the diameter of the TO base of the TO package laser.

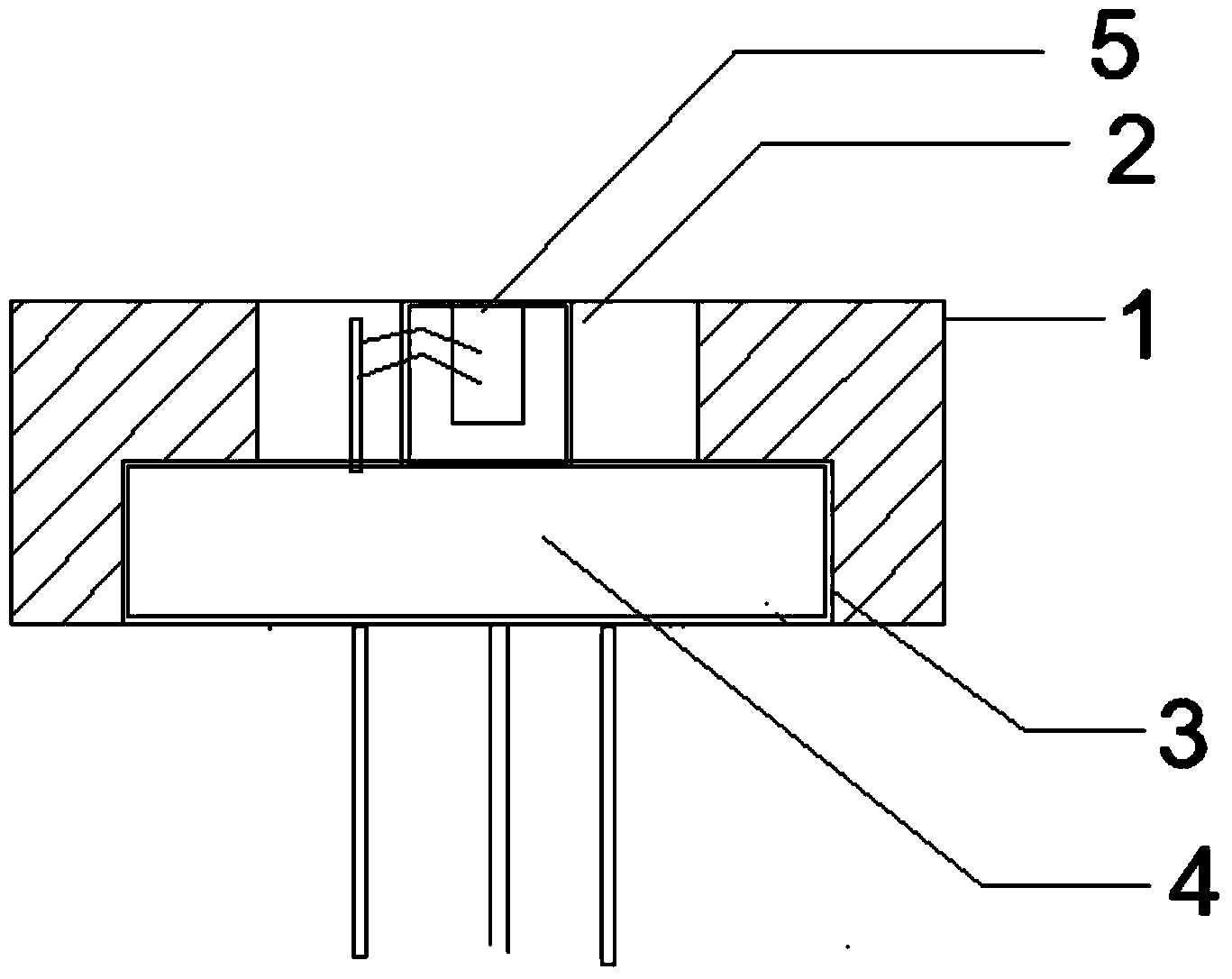

[0025] (2) if figure 2 As shown, assemble the TO package laser 4 into the figure 1 In the large hole 3 of the circular metal substrate 1 shown, the TO socket of the TO packaged laser 4 forms an interference fit with the large hole 3 , and the front cavity surface 5 of the TO packaged laser is flush with the small hole 2 .

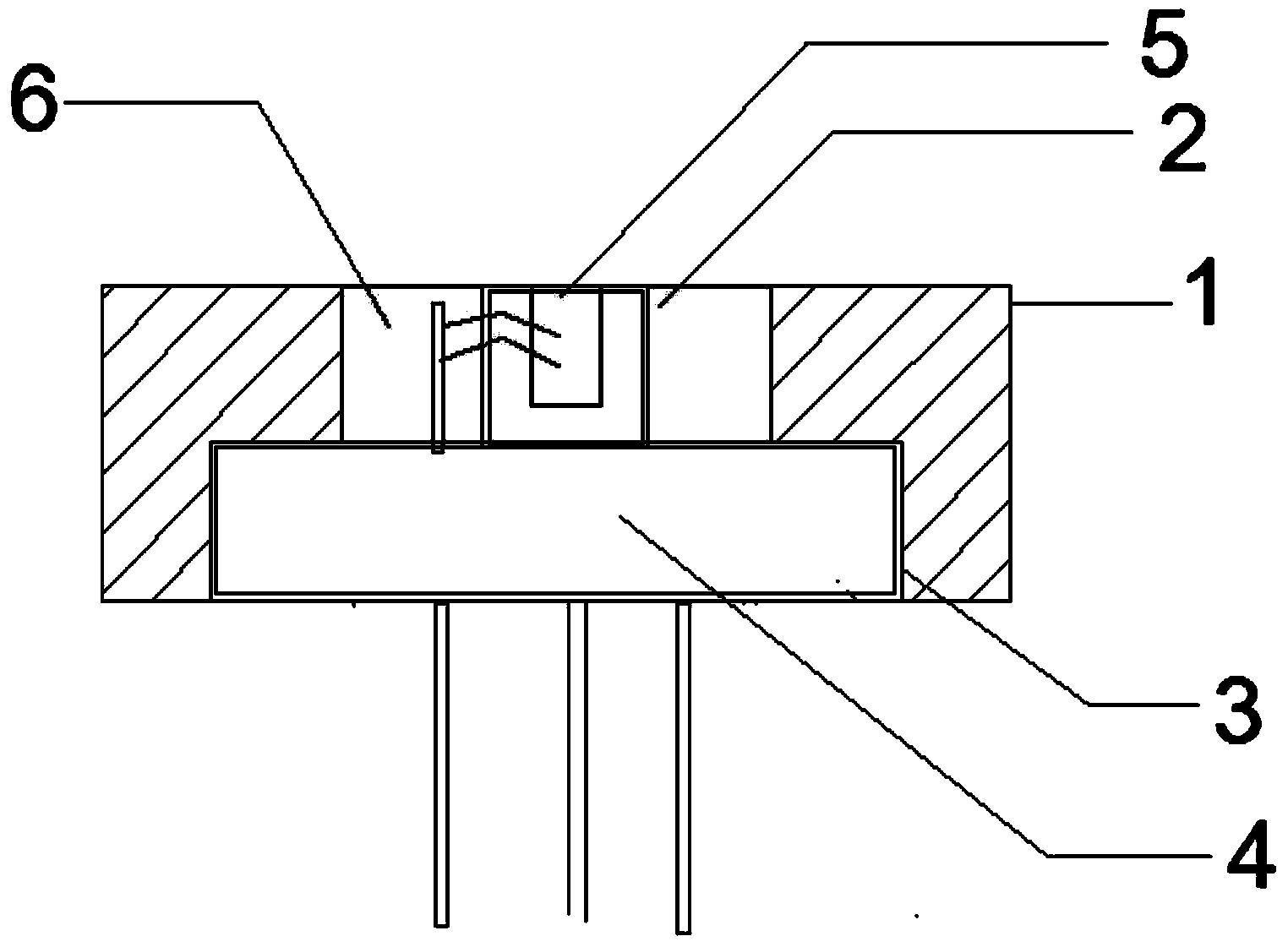

[0026] (3) if image 3 As shown, the space of the small hole 2 is filled with a heat-conducting adhesive 6 (curable type such as heat-conducting silica gel), and the height of the heat-conductin...

Embodiment 2

[0032] This embodiment is the manufacture of a C-mount packaged laser, including the following steps:

[0033] (1) production Figure 4 The metal substrate 1 shown has a square or circular shape with a circular or square blind hole 7 inside. The depth of the blind hole 7 is consistent with the height of the C-mount heat sink of the C-mount packaged laser 8 .

[0034] (2) if Figure 5 As shown, the C-mount packaged laser 8 is fixed in the blind hole 7, and the front cavity surface 5 of the C-mount packaged laser 8 is flush with the blind hole 7 (that is, flush with the square metal substrate 1).

[0035] (3) if Image 6 As shown, the space of the blind hole 7 is filled with heat-conducting adhesive, and the height of the heat-conducting adhesive is smaller than the front cavity surface of the C-mount packaged laser 8 .

[0036] (4) Put the laser on the metal substrate 1 in an oven lower than 70°C, and cure it at 60°C-70°C for 20-30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com