Heat radiator module special for concentrating photovoltaic solar heater

A concentrating photovoltaic and radiator technology, applied in the field of solar power generation, can solve the problems of increasing product cost, increasing the cost of connecting wires and external power supply, increasing production workload, etc., and achieves processing efficiency, low production cost, and improved heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

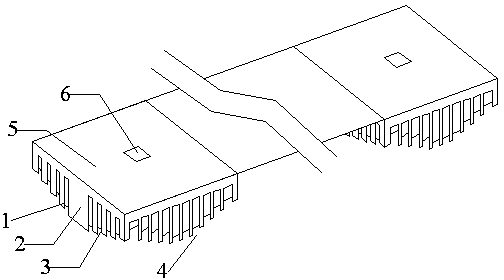

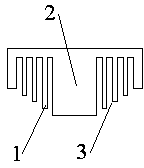

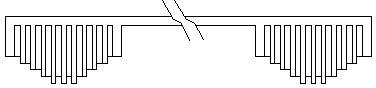

[0019] A special radiator module for concentrated photovoltaic solar energy, such as Figure 1~6 As shown, it includes secondary cooling fins 1 , main cooling fins 2 , radiator bottom plate 5 , and installation area 6 for concentrating photovoltaic photoelectric conversion receivers. The secondary cooling fins 1 are composed of multiple rows of cylindrical arrays or multiple rows of elliptical cylindrical arrays and a graphic array formed by splicing the surrounding arrays into squares and semicircles. The secondary cooling fins 1 start from the center of the main cooling fins. 2 Arranged in descending order according to the height, the inner and surrounding arrays of the secondary heat dissipation fins 1 are staggered in pairs, the main heat dissipation fins 2 are arranged in a row of rectangular column arrays, and the main heat dissipation fins 2 are two Above, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com