Method for physically treating complexing metal ion wastewater

A technology of complex metal and physical method, applied in the field of complex metal ion wastewater treatment, can solve the problems of membrane blockage, cumbersome process, troublesome regeneration, etc. in the membrane treatment method, achieve recycling, overcome high replacement frequency, prevent membrane blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

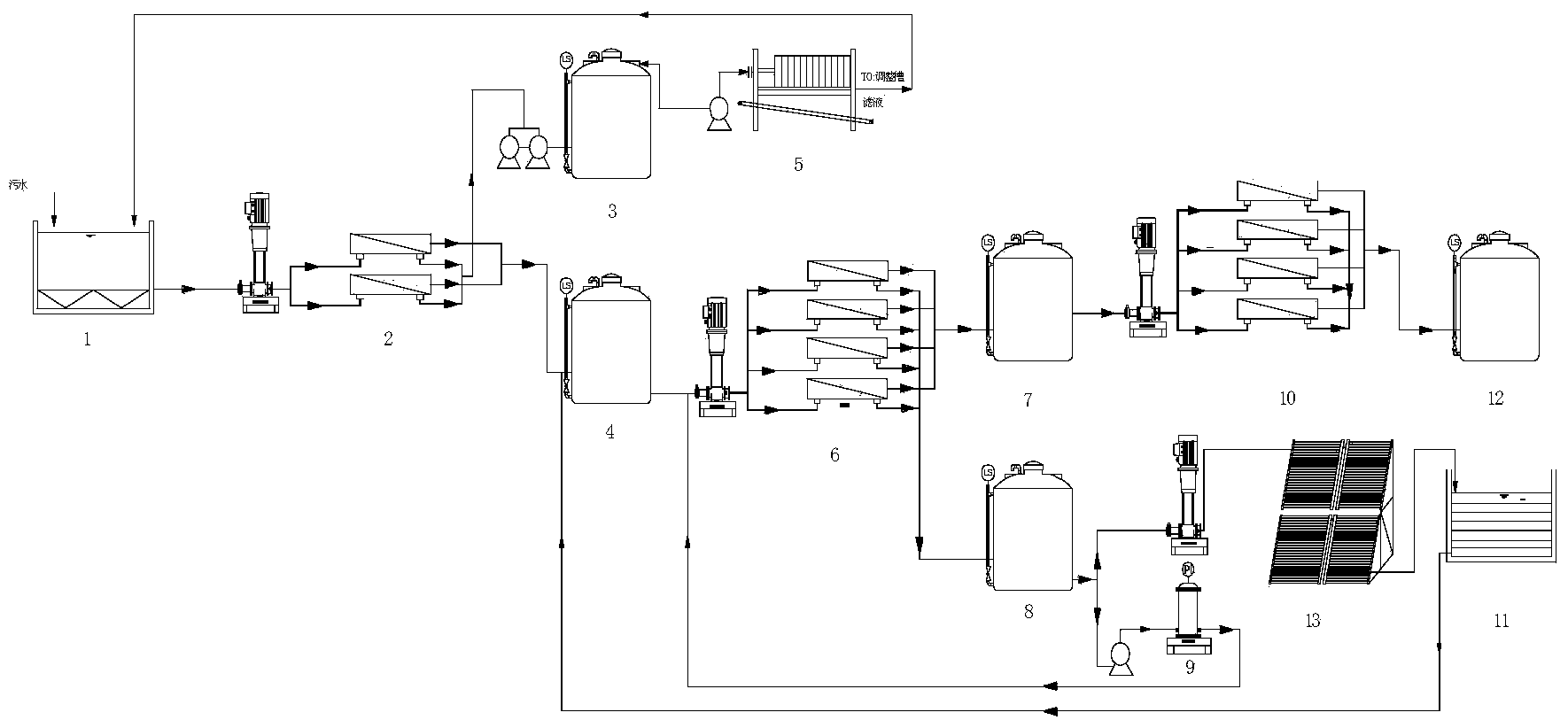

[0022] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Collect the comprehensive wastewater with high turbidity and metal content of about 0-1g / L into the collection pool 1, and enter the microfiltration processor 2 at a high speed under the pressure of 1.5-4.5MPa through a high-pressure pump to separate fresh water and concentrated water , the fresh water is buffered by the intermediate water tank 4 and then enters the nanofiltration concentration membrane group 6 for further separation, the concentrated water enters the filter press 5 through the intermediate water tank 3 for further purification and separation, the liquid is purified, and the liquid returns to the original water pool 1; nanofiltration concentration The concentrated water separated by the membrane group 6 is filtered through the intermediate water tank 8 and the precision filter 9, and then concentrated repeatedly in the nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com