Application of an upflow anaerobic-biocatalytic electrolysis coupling enhanced refractory wastewater treatment device

A biocatalytic electrolysis and upflow anaerobic technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of weak tolerance to toxicity, lack of stability, Low efficiency of toxic waste water and other issues, to achieve strong shock load resistance, good effluent quality, and good biological film hanging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

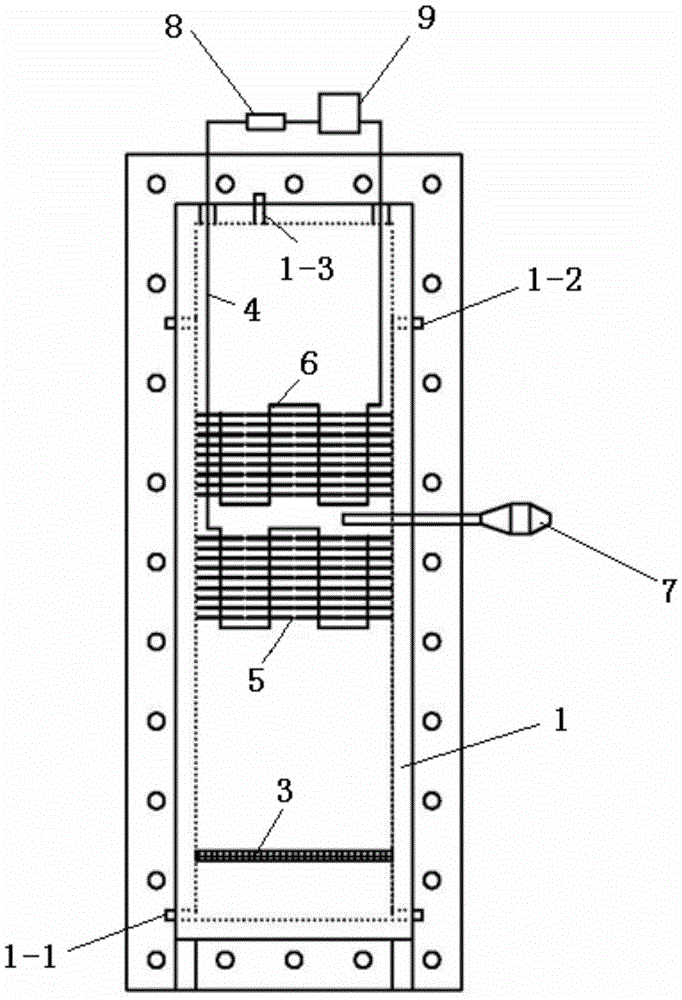

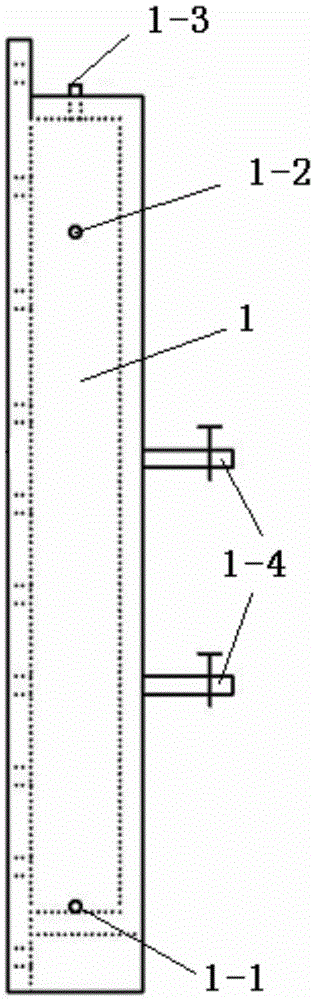

specific Embodiment approach 1

[0033]Specific embodiment 1: In this embodiment, an upflow anaerobic-biocatalytic electrolysis coupling enhanced refractory wastewater treatment device consists of a reactor main body 1, a cover plate 2, a water distribution plate 3, a titanium wire 4, a cathode 5, and an anode 6 , a reference electrode 7, a resistor 8 and a power supply 9; wherein, a water inlet 1-1 is respectively set on the left and right sides of the lower part of the reactor main body 1, and a water outlet 1-2 is respectively set on the left and right sides of the upper part of the reactor main body 1 , the air collecting holes 1-3 are arranged on the top of the reactor main body 1, and the two sampling ports 1-4 are arranged on the front of the reactor main body 1; the water distribution plate 3, the cathode 5 and the anode 6 are arranged inside the reactor main body 1, The anode 6 is higher than the cathode 5, the water distribution plate 3 is close to the water inlet 1-1, the cathode 5, the resistor 8, ...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is: cathode 5 is made up of 8 carbon brushes connected in series by titanium wire 4, and the diameter 25 of brush is mm, and length is 40mm; Anode 6 is made up of 8 carbon brushes connected in series by titanium wire 4 Composed of carbon brushes, the diameter of the brush is 25mm, and the length is 40mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment is different from Embodiment 1 in that: the diameter of the titanium wire 4 is 1 mm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com