A kind of novel cement mixture material and its preparation method and application

A technology of mixed materials and cement, which is applied in the direction of cement production, etc., to achieve the effects of shortening the setting time, improving the strength in the later stage, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

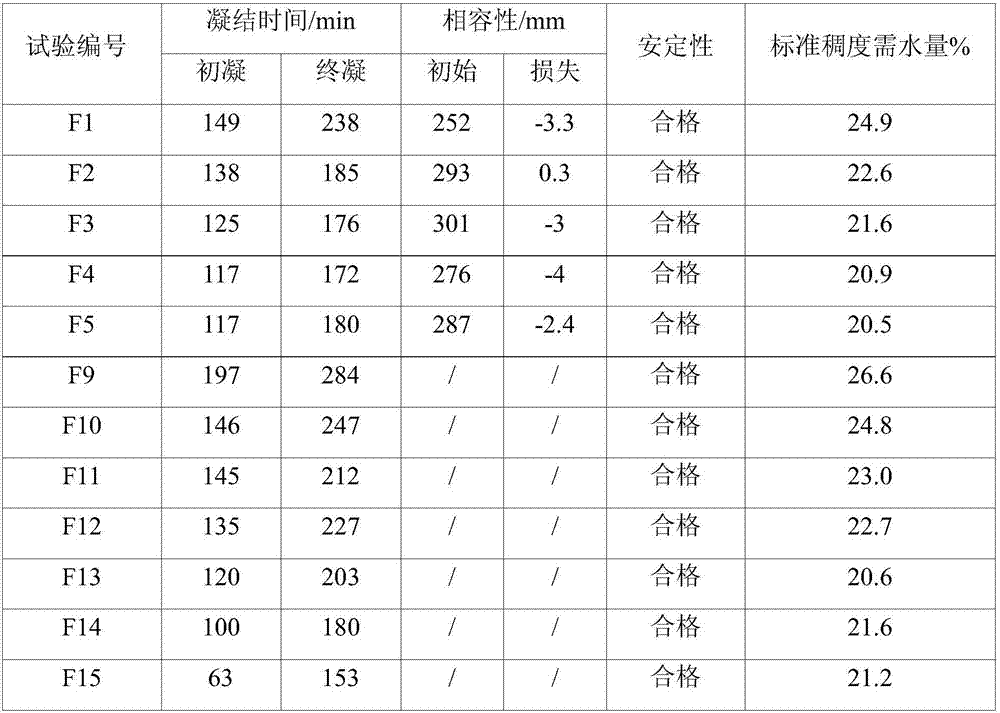

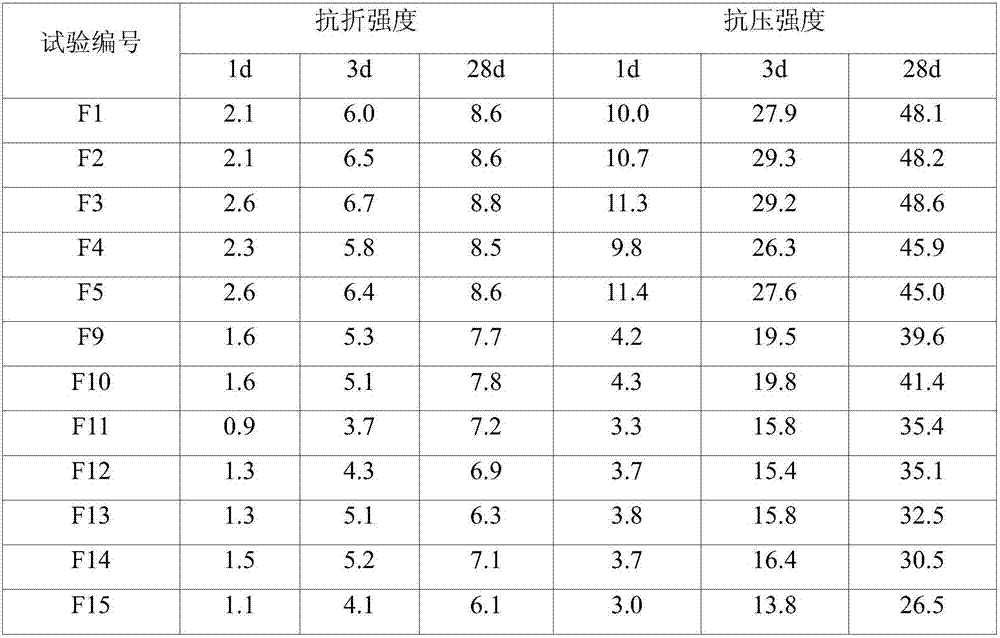

Examples

Embodiment 1

[0064] Embodiment 1 Preparation of novel cement mixture material slag balls of the present invention

[0065] A. Mixed raw materials: The raw materials are calculated as dry matter, and the following weight ratios are used for mixing:

[0066] 1 part papermaking white mud

[0067] Carbide slag 1~2 parts

[0068] At least one kind of 0.5-3 parts of wind ash and high-chlorine and high-alkali kiln dust is released in the bypass;

[0069] B, stirring: add the water of 3 times amount of raw material total amount in the mixed raw material and dilute, stir with 50~100rpm, precipitate; After testing, the used bypass wind ash of the embodiment of the present invention, high chloride high alkali kiln dust chloride ion content More than 1.5%, so 0.01% to 0.1% precipitant anionic polyacrylamide was added during mixing;

[0070] C. Stand still: Control the standing conditions: the temperature is 100°C to 120°C, the time is 12h; the pressure does not exceed 0.1MPa;

[0071] D. Separation:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com