Thick BZT film having EC effect, and its making method

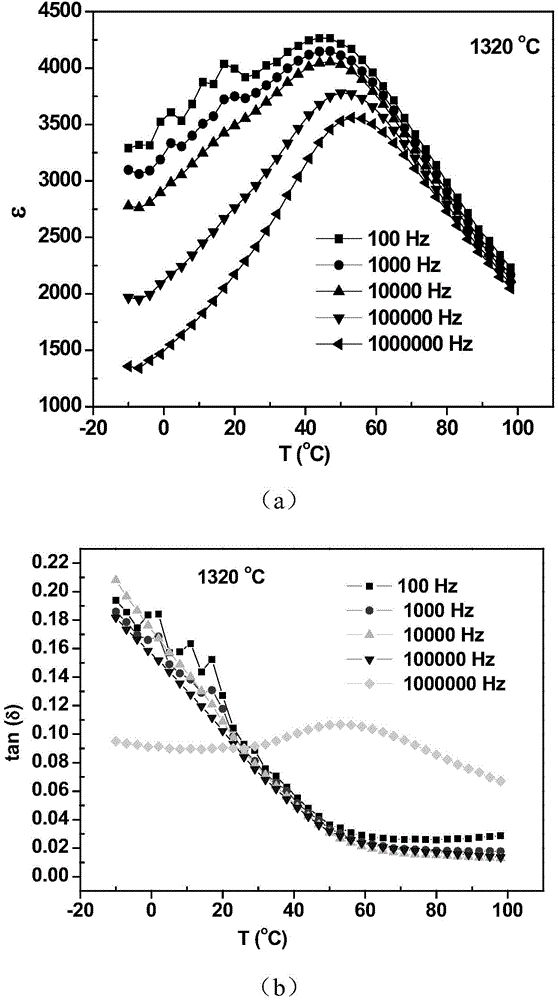

A thick film and effect technology, applied in the field of BZT thick film and its preparation, can solve the problems of ECE concept understanding and measurement technology immature, weak electrothermal effect, etc., to achieve the effect of reducing dielectric loss and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

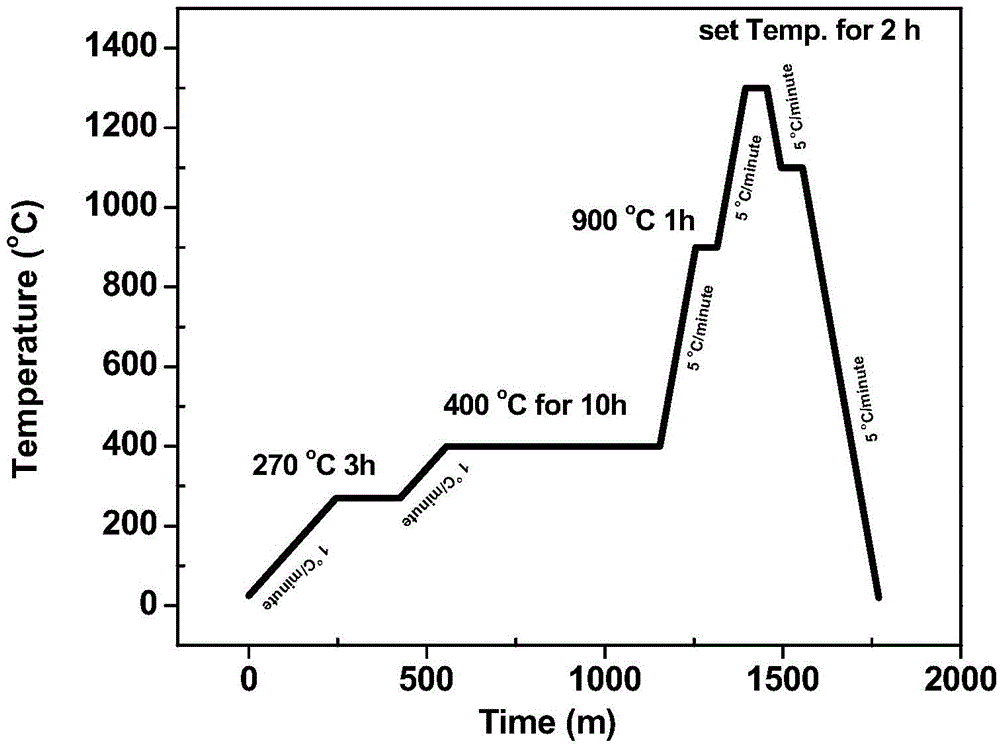

[0030] The invention provides a kind of preparation method of the BZT thick film with EC effect, comprises the following steps:

[0031] 1) Preparation of calcined powder

[0032] BaCO 3 、TiO 2 , ZrO 2 Weighing according to the mass ratio of 1:1:0.3, ball milling, and then pre-calcining at 1200°C for 2 hours to obtain pre-calcined powder;

[0033] 2) Preparation of slurry

[0034] Ball mill the calcined powder, add casting agent A and casting agent B, and prepare Tape-casting slurry, wherein, casting agent A is a mixed solution of 95% ethanol and methyl ethyl ketone and 5% PVB Composed according to any proportion; the casting agent B is composed of a mixed solution of ethanol and butanone with a concentration of 65-70%, PVB with a concentration of 20-25% and a plasticizer with a concentration of 10-15% according to any proportion; wherein, The mass ratio of calcined powder to casting agent A and casting agent B is 1:0.2:0.3;

[0035] 3) BZT thick film preparation

[003...

Embodiment 2

[0038] The invention provides a kind of preparation method of the BZT thick film with EC effect, comprises the following steps:

[0039] 1) Preparation of calcined powder

[0040] BaCO 3 、TiO 2 Weighing according to the mass ratio of 1:0.7, ball milling, and then pre-calcining at 900°C for 8 hours to obtain pre-calcined powder;

[0041] 2) Preparation of slurry

[0042] Ball mill the calcined powder, add casting agent A and casting agent B, and prepare Tape-casting slurry. Among them, casting agent A is a mixed solution of 90% ethanol and methyl ethyl ketone and 10% PVB Composition according to any proportion; Casting agent B is composed of a mixed solution of ethanol and methyl ethyl ketone with a concentration of 70%, PVB with a concentration of 25% and a plasticizer with a concentration of 15% according to any proportion; wherein, calcined powder and casting The mass ratio of agent A and casting agent B is 1:0.6:0.6;

[0043] 3) BZT thick film preparation

[0044] The...

Embodiment 3

[0046] The invention provides a kind of preparation method of the BZT thick film with EC effect, comprises the following steps:

[0047] 1) Preparation of calcined powder

[0048] BaCO 3 、TiO 2 , ZrO 2 Weighing according to the mass ratio of 1:0.8:0.2, ball milling, and then pre-calcining at 1000°C for 6 hours to obtain pre-calcined powder;

[0049] 2) Preparation of slurry

[0050] Ball mill the calcined powder, add casting agent A and casting agent B, and prepare Tape-casting slurry. Among them, casting agent A is a mixed solution of 94% ethanol and methyl ethyl ketone and 8% PVB Composition in any proportion; Casting agent B is composed of a mixed solution of ethanol and methyl ethyl ketone with a concentration of 68%, PVB with a concentration of 24% and a plasticizer with a concentration of 12% in any proportion; wherein, calcined powder and casting The mass ratio of agent A and casting agent B is 1:0.4:0.4;

[0051] 3) BZT thick film preparation

[0052] The prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com