Fireproof door core plate sheet material and preparation method thereof

A fire door core and board technology, applied in the field of building materials and building fire protection, can solve the problems of fragile fire resistance, foam cement board easy to absorb water, corroded door panels, etc., achieve good fire resistance and heat insulation performance, mature preparation method, enhanced The effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

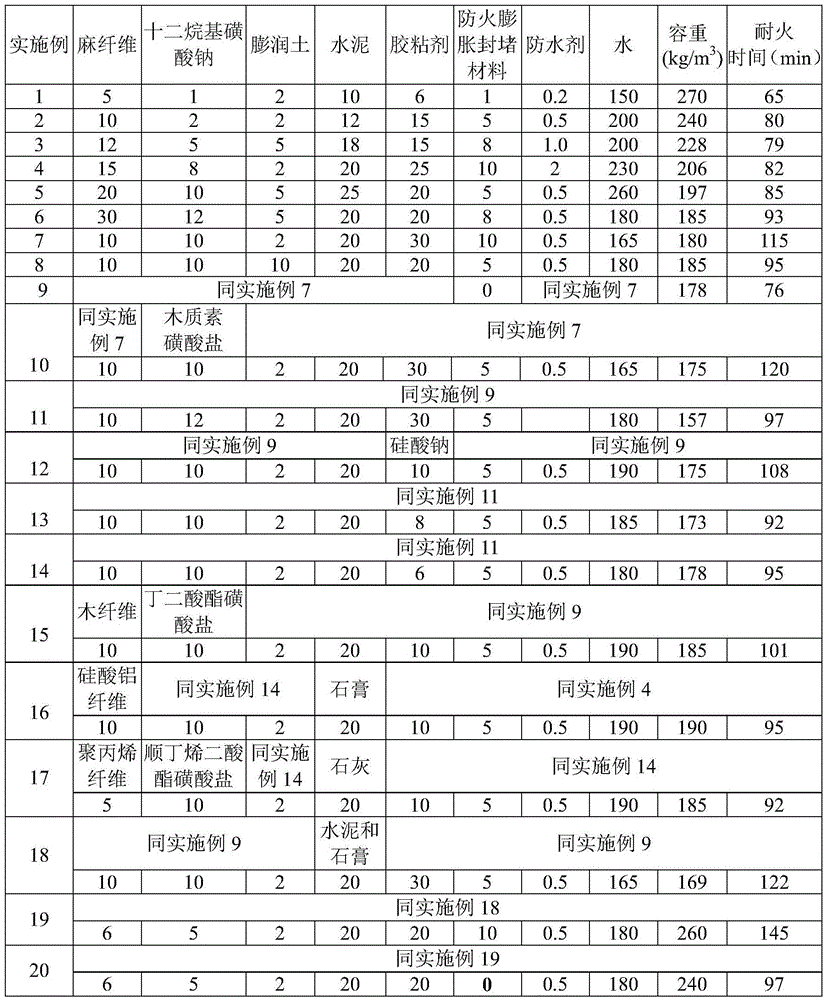

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

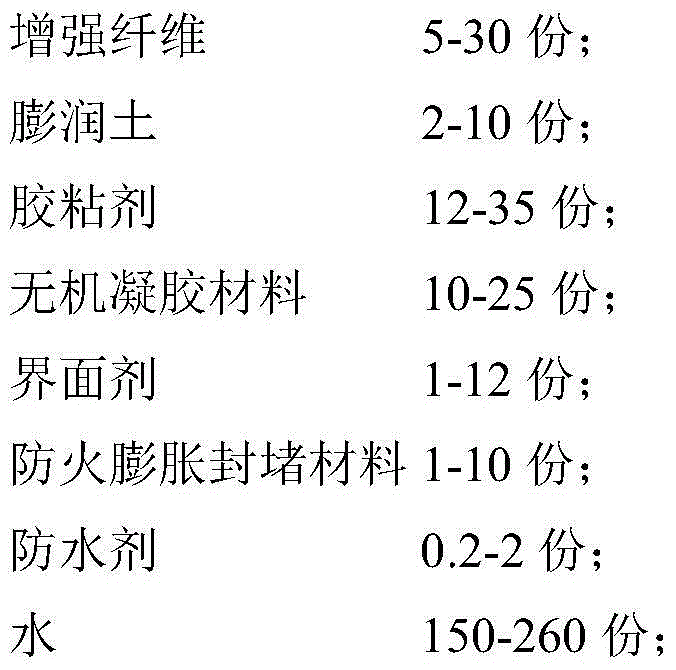

[0025] A fireproof door core board of the present invention, its components and parts by weight are: 5-30 parts of reinforcing fiber, 2-10 parts of bentonite, 12-35 parts of adhesive, 10-25 parts of inorganic gel material, 1-25 parts of interface agent 12 parts, 1-10 parts of fireproof expansion plugging material, 0.2-2 parts of waterproofing agent, 150-260 parts of water.

[0026] The reinforcing fiber in the present invention makes the material have certain flexibility and good mechanical strength, and described reinforcing fiber is a kind of in glass fiber, aluminum silicate fiber, polypropylene fiber, wood fiber, bamboo fiber and hemp fiber, preferably wood fiber or hemp fiber.

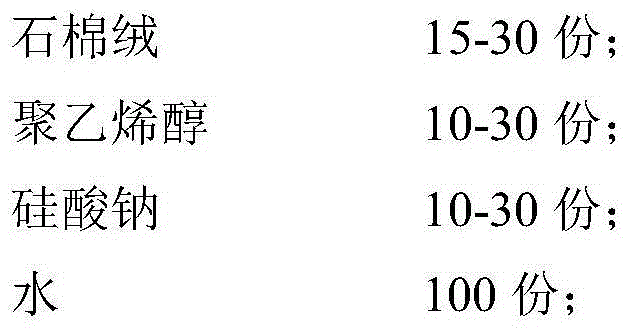

[0027] The adhesive and the inorganic gel material in the present invention can keep the foam produced in the preparation process; the adhesive is one of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com